The mainsail of our Chesapeake Bay test boat was intact, but, after exhausting every life-extending option available—including patches, repairs, re-stitching, and tune ups—it became obvious that the sail was on its last legs.

As with any big-ticket item, purchasing a new main involves a number of choices, each of which are driven by an equally diverse list of factors to consider, from the type of boat (cruiser or racer) and area sailed (inshore, coastal, or blue water) to the type of sailor you are (i.e. a performance-oriented hard charger or someone with a more laid-back approach).

To help with our mainsail replacement mission, we turned to Baxter Sailmakers Ltd., a well-respected loft located in Norfolk, Va. Owner David Baxter brought a wealth of knowledge to the project and proved to be a valuable sounding board while considering the various options available. Baxter is hardly alone in this category. Although franchise affiliates garnered the lion’s share of recommendations in our recent reader poll some of the highest encomium went to independent sailmakers like Baxter.

Sail Selection Factors

Many of the decisions we faced were easily answered based on a realistic review of our boat, future sailing plans, and a review of existing mainsail pros and cons we’d noted throughout the years. Our test boat is a 36-foot Union cutter, a full-keel, heavy-displacement cruiser reviewed in the February 2010 issue. Future sailing plans include cruising Chesapeake Bay and the East Coast, with the occasional Caribbean crossing thrown in.

Once these initial questions were answered, the actual decision-making fun began in earnest. These included decisions about sail construction (cost, cloth, weight, number of reefs, etc.) as well as possible upgrades to the flaking system, track system, reefing setup, and similar details. Here’s a step-by-step account outlining the major options and selection process for our new mainsail, along with the reasoning behind each decision. While your decisions at each step may vary, the exercise can help serve as a template for your own mainsail search.

Material

Our old main was constructed of Dacron, and while we may have briefly fantasized about the use of some exotic fiber or laminate, in the end, polyester continued to offer the best balance of cost, longevity, and performance for our particular situation. We decided to go with a premium-grade polyester (Dimension 360AP-MTO 8.4 ounce) that was described by our sailmaker as bulletproof and virtually maintenance free.

Premium polyester is tightly woven and has a high yarn count that provides good shape retention and good performance over a wide range of wind speeds. Other benefits include durability, longevity, UV stability, softer “hand” (feel of the cloth), and lower cost.

As to cons, polyester cannot deliver the same weight savings or shape that you find in high-tech laminated or fiber-reinforced cloth; however, we decided that the materials benefits made up for any loss of performance. (You can only squeeze so many knots from a Union 36.) From a cruising perspective, we felt that laminated sails didn’t offer the best value with regards to longevity, particularly as they are still subject to delamination and mildew issues despite a number of advances in the manufacturing process.

Corners, Clews, and Eyes

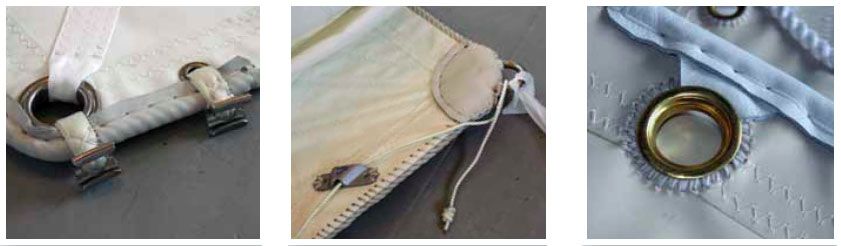

A few “traditional” sailmakers feel that hand-stitched elements at the corners and clew (see photos) are the best option for cruisers, on the basis that they better spread loads and are more easily serviced or repaired at sea by the owner. Others say there is nothing wrong with high-quality pressed-in eyes, as the cloth will typically fail before the hardware tears out or fails. Our existing main used a riveted aluminum headboard and pressed eyes. As both served us well over the years with no failure, we opted to use them with our new main as well. There is a difference in quality of pressed eyes, however. We used all stainless-steel eyes supplied by the Swedish sailing hardware company Rutgerson Marin.

Batten Banter

One of the first post-cloth decisions you’ll have to make is whether your new main will utilize full-length battens. There are a number of pros and cons regarding full-length battens and a wide range of opinions on their merits for cruising. Some cruising sailors choose to forego battens altogether, but if you want your mainsail to have a decent amount of roach, you’ll need some form of batten support.

On the plus side, a full-battened mainsail holds its shape longer and is easier to stow (particularly with furling devices such as lazy jacks, etc). Battens allow more roach, which enhances sail performance, and also dampen sail flogging, which increases sail life and reduces noise during hoisting, dousing, and reefing.

On the downside, full-battened sails are more complicated to build and add considerable expense to the sail. Fully battened sails are also a bit more difficult to race with, as the sail is “locked” into one shape, reducing adjustment options. It’s also more difficult to tell when a full-battened sail is out of trim. Battens can chafe the sail and the pockets that hold them, and they are prone to hanging up on standing and running rigging when the mainsail is raised, reefed, or doused. Batten pockets are a primary source of mainsail repairs. Battens put significantly higher loads on the track and cars, and they also increase the stack height of the sail luff.

Our old main had full-length battens, and in our mind, the benefits provided by a battened main outweighed the negatives. However, in light of our experience with a full-battened main, we decided to try a hybrid approach — a “2-plus-2” configuration, with two full battens at the top, and two partial battens at the bottom.

On the plus side, partial battens make the sail more adjustable with minimal loss of performance (as compared to a full-batten sail). The sail is also easier to trim when hard on the wind. Since the top two full battens are still relatively short, they don’t hinder the raising or lowering of the sail.

The two partial battens still distribute the load across the sail well, but their shorter length means there is less compression at the luff. This reduced friction on the luff track makes it easier to reef. A partially battened main is easier to remove from the mast—when the need arises—than a full-battened one. It is slightly cheaper to build, and matching the length of the partial battens with the longest full-length batten reduces the number of spare battens needed. A well-made and well-cared-for, partially battened sail can deliver 10-plus years of good service.

As to downsides, a partially battened main is not as easy to stow as a full-battened one, and while the 2-plus-2 setup dampens flogging, a full-batten main does it even better. This also means the partially battened sail will lose its shape quicker.

Reef points

Once we decided on our batten style, next up was the number and position of reef rows to reduce mainsail area during heavier winds. Our existing main had three reef rows, each consisting of a secondary tack and clew cringles and intermediate reef points used to secure the bunt of the sail when reefed.

The primary decision with our new sail was the number of reef points. While the existing three rows may have provided more reefing options, we rarely (if ever) used the third reef, which also complicated things by adding additional running rigging.

After discussing the pros and cons with our sailmaker, we opted for two reefs rather than three. The first reef reduces the mainsail area by 15 percent, while the second is at 29 percent. Some sailmakers might suggest an even deeper reef (say 40 percent), to allow the main to function as storm trysail.

Baxter’s opinion was that trying to make the main do everything was not the best approach in our case, particularly since reefing the main to the size of a storm trysail would result in poor sail shape and less-than-ideal performance. He suggested that two reefs in conjunction with a proper storm trysail would better serve our occasional bluewater aspirations should the weather turn heavy. (For more on trysails, see “A Tale of Two Trysails,” August 2008.)

Another upgrade we made was installation of “quick cringles” (aka “easy reefs”), which consisted of a length of webbing through each reef cringle with a stainless-steel ring sewn in on both sides. The rings make reefing quicker and easier than trying to fit the reef cringle over the reef hook, while also reducing sail chafe and distortion. Some cruisers have added Dacron straps at the luff and small blocks at the clew to help pull down the main for reefing, but we opted not to have these features.

Loose Foot or Fixed

Another change from our old sail was the decision to go with a loose-footed main. Our old main had a substantial outhaul car and was also attached to the boom along its entire length, a belt-and-suspenders approach that our sailmaker deemed unnecessary. In addition to being easier to bend on and remove, a loose-footed main offers other advantages, such as easier and more efficient sail trimming. One possible downside would be the higher loads placed on the outhaul car (if not sufficiently robust).

Taming The Main

Our old mainsail utilized a Dutchman stowage system (installed by a previous owner). We considered other flaking systems for our new main (lazy jacks, lazy jack/sail cover combos, etc.), but we’ve been pleased overall with Dutchman system and decided to use it with our new main as well.

One change we made was to go with the Dutchman’s 40-3A system, which has three control lines, instead of the previously installed two-line model. Based on conversations with the manufacturer, the 40-3A was the correct system for our sail and would provide better control and performance. By sending in the tabs from our old Dutchman, we qualified for a 30 percent trade-in discount.

For more on mainsail handling options (including the Dutchman system) check out the February 2008 issue.

Slippery Upgrades

Once the basics of our new mainsail were decided, the next step was to review possible upgrades to the system as a whole. After discussing the various options available, our sailmaker stated that the biggest “bang for the buck” upgrade we could make would be to eliminate our friction-inducing external slides by installing a Tides Marine Strong Track and Slide System. The system is a mainsail luff track and slide assembly that greatly reduces the friction normally associated with raising and lowering the mainsail. The track is a single length of low-friction, ultra-high molecular weight polyethylene plastic (UHMPE) that is machined to slide onto your existing mast track. Installation is simple, straight forward, and the results when raising and dousing our new sail are nothing short of amazing.

Another great recommendation by our sailmaker was to upgrade our batten cars to Schaefer Battslide receptacles. The Battslide units (which accept both flat and round battens) allow front-end loading and batten adjustment at the mast. Front-end loading allows you to keep the leech of the sail closed (making it impossible for a batten to slip out through the leech), while the batten-tension adjustment feature makes it easier to maintain proper sail shape.

Although Schaefer doesn’t make a slide that fits the Tides Marine Strong Track system, the Tides Marine #400 slide fit the Battslide cars perfectly and provided full articulation, which makes raising and lowering the sail easier while reducing batten compression loading.

Conclusion

Purchasing a new main is big deal for the average sailor, an event that most cost-conscious cruisers go through only a handful of times in their sailing life. This infrequency makes it a heady experience, one that’s equal parts anticipation and trepidation as you wade through the various options and select those that will (hopefully) produce that perfect sail. As with any major project, combining your own experience with research and the advice of a professional will go a long way toward ensuring you reach mainsail nirvana. At the heart of this experience is the relationship with the sailmaker. A good sailmaker will patiently listen to your expectations and explain the various options, and more importantly, will stand by you after the sale. For those just starting their search, a list of reader-recommended sailmakers that appears online with this article is a good place to start.

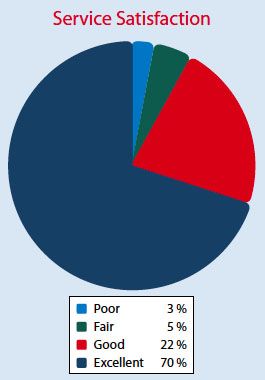

Our informal online sailmaker poll generated 336 complete responses, not large enough to be statistically significant, but still useful, in our opinion. In total, readers recommended more than 100 different lofts. The responses are subjective to each respondent’s experience, making it impossible to fairly rank sailmakers based on the poll, so readers should consider this report an overview and use it accordingly in any sailmaker search. The responses can offer some insight into what can be expected of a specific sailmaker and what should be considered in the selection process.

Sixty percent of the respondents said they used their boat for cruising, while 31 percent used their boat for racing as well as cruising. Just over 6 percent identified themselves purely as racers. Most (63 percent) identified their sail material as premium Dacron.

The good news was that 70 percent of our readers rated their sailmaker’s service Excellent, and 22 percent rated the sailmaker’s service as Good. Close to 90 percent of the respondents had purchased sails in the previous five years.

Below are general findings regarding the most frequently recommended sailmakers in the poll. More detailed survey results are available at the website http:// questionpro.com/s/1-288131-1841644. A complete listing of all the sailmakers recommended in this poll will accompany the web version of this article at www.practical-sailor.com. We will also be publishing select comments from the survey on the Inside Practical Sailor blog, which is accessible through the top menu of our website.

North Sails (www.northsails.com) – Of the major “franchise” sailmakers, North Sails was the most popular brand, with 42 respondents saying their sails were built by North affiliates. The lofts were from all over the country. The highest number of respondents (six), said they bought their sails in Annapolis, Md. Nearly one-quarter (10) reported a problem. In the ratings for overall service, the votes were as follows: Excellent, 19; Good, 14; Fair, 3; Poor, 6. Of the major national franchise sailmakers in our survey, North had the lowest percentage of customers satisfied with overall service. The chief complaint was generally the lack of personalized attention and poor after-sale service.

Doyle (www.doylesails.com) – Twenty-four respondents said they had their sails made at Doyle affiliates, almost all of them at East Coast lofts. Only one respondent reported a significant problem with his sail, which he said was quickly rectified with a personalized visit from the sailmaker. In the ratings for overall service, the votes were as follows: Excellent, 20; Good, 4. Respondents generally praised the lofts’ after-sales service.

Quantum (www.quantumsails.com) – Twenty-three respondents said they had their sails made at Quantum lofts. The locations were primarily on the East Coast, with lofts in Rhode Island (four), Annapolis (four), and Seabrook, Texas (three), making up the greatest number of respondents. In the ratings for overall service, the votes were as follows: Excellent, 13; Good, 7; Fair, 2; Poor, 1. Most respondents praised the level of service, although three respondents (two from Texas) stated they were not happy with details such as corner reinforcement in the clew area.

UK Halsey (www.ukhalsey.com) – Fourteen respondents said they used lofts affiliated with UK Halsey, the highest number (four) were served by the loft in City Island, N.Y. In the ratings for overall service, the votes were as follows: Excellent, 6; Good, 5; Fair, 2; Poor, 1. Criticism centered on after-sales service, which was praised by the majority of the respondents.

Not every sailor has a selection of local sailmakers to choose from. He or she must instead rely on Internet research and phone conversations to find the best sail for the best price. As most of the world’s sail production takes place in a handful of high-volume production lofts abroad (China, Sri Lanka, and Africa), U.S. sailmakers have taken on the role of sail designers— rather than sailmakers.

In our recent study of mainsails, we found that sails made abroad make excellent value, thanks in large part to computeraided design and panel-cutting. Nevertheless, the sailor needs to be specific regarding the measurements and the details of construction, and his relationship with the sail designer/salesman is as important as ever—particularly in the event that something goes wrong.

Locally built or finished sails tend to be more expensive, but the advantage of having a sailmaker check your measurements on board and then make sure the sail fits and performs as designed is often worth the extra money. This kind of attention is also possible with offshore-built sails from major lofts, so long as the sales rep regards this as part of his job.

During the design of our main, the sailmaker spent over an hour onboard measuring the hoist, outhaul, etc, as well as answering our questions and discussing the various options available. As with any major purchase, there’s a good deal of reassurance in knowing that the person selling you the sail is the one that will be making it and is willing to join you for a sea trial to answers questions or address problems should they arise.

Global Doyle Evolution Sails Far East Sails Halsey Lidgard Hood Sailmakers Island Planet Sails Lee Sails Mauri Pro Sailing Mauri Sails North Sails Quantum Sail Design Group Rolly Tasker Sails UK-Halsey Ullman Sails

Canada North Sails Toronto Triton Sails North Sails Vancouver North Sails Vacouver ShoreLine Sails Voile Saint-Onge

South Africa Quantum Sails South Africa

U.S. National JSI North Sails Direct The Sail Warehouse

California Elliott / Pattison Sailmakers Glaser Sails Morrelli Performance Sails Santa Cruz Sails SLO Sail and Canvas Ullman Sails Long Beach Ullman Sails San Diego/Seattle

Colorado Kelly-Hanson Sails

Connecticut Z sails

Florida Atlantic Sail Traders Bremen Sails Emerald Sails Knighton Sailmakers Mack Sails National Sail Supply North Sails Gulf Coast Smyth Team Sails (850-243-WIND) Super Sailmakers (Doyle loft) True North Sails

Illinois Doyle Midwest North Sails Chicago Sterling Sails (773) 523-4449 UK-Halsey Chicago

Indiana Sailrite

Louisiana West Wind Sails (985) 626-5638

Maine Bayview Sails and Rigging Bluffton Bay Sails Bohndell Sails E.S. Bohndell Sailmakers Hallett Canvas and Sails Maine Sailing Partners Nathaniel S. Wilson, Sailmaker

Maryland Ace Bacon Sails Doyle Chesapeake North Sails Annapolis North Sails Chesapeake Quantum Sails Annapolis Quantum Solomons Island Scott Allen Sailmakers

Massachusetts Downs Sails Doyle Boston Doyle Buzzards Bay Doyle Manchester Squeteague Sailmakers

Michigan Doyle Sails Detroit North Sails Detroit Quantum Sails Traverse City

Montana Taylor Sailmakers (406) 755-4218

New Jersey Eggers Sails, Inc Hendrickson Sailmakers Linthicum Sailmakers North Sails – New Jersey

Oklahoma Kerr Sailmakers

New York Bay Sails (a Haarstick Loft) Doyle Ploch Sailmakers Doyle Sailmakers Long Island Haarstick Sailmakers Quantum Sails Long Island Somerset Sails

North Carolina Omar Sailmakers

Rhode Island North Sails Intensity Sails Thurston Sails

South Carolina FX Sails North Sails South Carolina Waters Sails

Texas C&C Sailmakers Cameron Sails Mariner Sails North Sails Kemah Quantum Sails Gulf Coast, Seabrook UK-Halsey Texas

Vermont Vermont Sailing Partners

Virginia Baxter Sailmakers Dabbler Sails Hampton, VA Sales & Sail Care Latell Sails North Sails Hampton Ullman Sails Virginia/Latell Sailmakers LLC

U.S. Virgin Islands Quantum Sails USVI

Washington Neil Pryde (Scott Rush, agent) Port Townsend Sailmakers Puget Sound Sails

Wisconsin Dorsal, LLC