At first glance, having an on-deck anchor locker looks as practical as having a trunk in an automobile. It appears to be a great place to stow the rode, hide the windlass, pack up the deck brush and a bucket, and perhaps even tuck away a few bulky fenders. Coastal and inshore sailors love the locker, but offshore cruisers and racers have mixed feelings about them, especially when it comes to poorly thought-out wells that have been cleaved into a boats foredeck.

For years, we have wandered the Annapolis and Miami boat shows, peeking into anchor lockers and recording the good, the bad, and the just plain poorly designed. This photo essay comes from the scrapbook of photos weve accumulated during these dockside tours and our adventures on various boats; the accompanying commentary is gleaned from lessons learned during bluewater voyages, coastal cruises, and inshore passages.

As with all things boat-design related, choosing between an anchor setup with an on-deck locker or one with a deck spill pipe and a belowdecks chain well comes down to weighing the pros and cons based on your needs and what type of sailing the boat will be doing. Whatever your situation-whether youre buying a boat or looking to get yours properly set up-here are a few points to consider in regards to the sensible anchor locker:

- All points of access should be able to be made watertight.

- The lead angle of the anchor chain to the windlass expedites rodehandling rather than being set to accommodate keeping the windlass undercover.

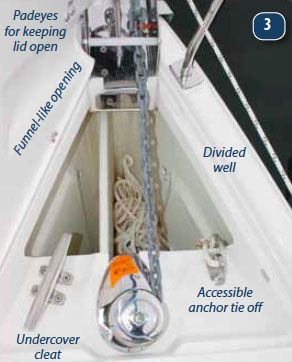

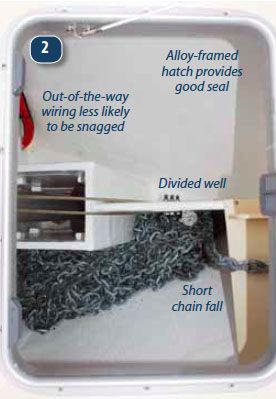

- There’s enough room for chain to castle (pile up as it is stripped from the windlass) and still provide a clear fall.

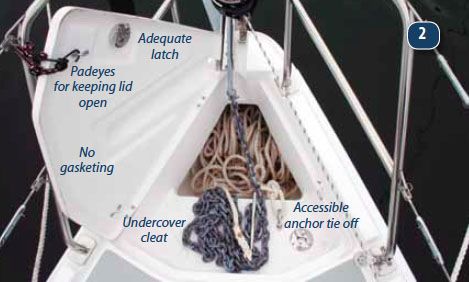

- Cleat leads and opening the locker do not conflict.

- The bitter end of the chain has a length of nylon rode connecting it to a hard point on the boat so that the rode can be untied or cut in an emergency.

- The windlass was chosen to fit the task at hand, not just to fit the locker.

A Dry Locker

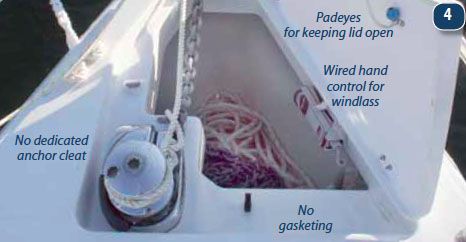

In the chain pipe versus anchor locker debate, one of the main arguments is that a contemporary on-deck anchor locker is much more difficult-often impossible-to make watertight. The International Sailing Federations (ISAF) Offshore Special Regulations treat anchor wells as cockpit volume. This is a clear indication that watertight status is not always in the cards, and in heavy weather, inundation may involve more than the drip from a wet anchor rode.

In heavy seas, even the lockers drains can become floodwater inlets, as PS Technical Editor Ralph Naranjo discovered on a lumpy passage from Bermuda. The boats crew learned the hard way what an anchor well full of water could do to decrease buoyancy and increase the pitching moment of a Swan 48 MKII. It took the repeated efforts of crew wedged in the forepeak to pump the locker dry using a permanently installed manual bilge pump.

Inspection found that the culprits were the two relatively small drain holes located just above the boats resting waterline. Through these, water gushed into the locker each time the bow plunged into a wave face.

While these drains were welcome features dockside and during coastal passages-they help keep the decks clear of anchor mud and other detritus from the depths-the euphemism locker drain takes on a whole new meaning at sea.

Lesson learned: Before going to sea, close off the anchor locker penetrations regardless of whether they’re on deck or in the hull, and regardless of whether they’re intended inlets or outlets.

Locker Design

Not all anchor lockers are created equal, as was evident during our boat-show walkabouts. Some had forward-facing anchor rode exits that were more spout-like entrances begging waves to enter; others were built in trench-like recesses that also invite water to follow a path of least resistance. Some were so shallow that only a few feet of chain rode would fit the chain box. A few doubled as a location for bow thruster relays and anchor windlass electrical accoutrements.

Placing a windlass in the recess of a well is walking the fine line of compromise. The upside is an uncluttered deck; the downside includes limited chain fall-the distance between the chain gypsy and the locker bottom-which can lead to problems with chain castling and links jamming in the gypsy.

Perhaps the biggest drawback is that in the event the locker floods during a passage, the windlass, solenoid, and junction box may be submerged for hours or days at a time. If the anchor windlass breaker has been left on, the stray current corrosion can be a very big deal, especially aboard aluminum boats.

And then theres the anchor lid. Boat designers often wrestle with how it should open and how it will function in concert with lines and cleats. The importance of a well thought-out design was highlighted during one PS editors recent charter aboard a 40-some footer.

The boat was anchored using a chain/rope rode secured to a twin set of cleats just aft of the anchor locker. When a formidable 0300 squall rolled in and the crew needed to get out a second anchor, they soon realized it was stowed in the on-deck locker, and the primary anchors rode ran straight across the locker lid, barring access. The rope rode, tight as a guitar string in the gale, would have to be rerun before the crew could extract the second anchor. In order to simply open the locker, the crew had to attach a line to the primary rode, put a block on the rail, and as the rode was slipped from the cleat, another crew transferred the tension to a cockpit winch.

Lesson learned: Be sure theres no conflict between cleat leads and the lockers opening; if there is, store essential gear elsewhere.

Construction Inspection

A peek into an anchor locker can give you a good idea of the boats construction quality. A boats stem area is usually free of laminate-hiding liners, and the curious consumer can see how well controlled the layup was, how the hull-to-deck joint was made, and what efforts were made to spread the loads linked to attached hardware. So while you scrutinize the line locker, also take a look at how the boat was built.

This quick inspection could save you from big headaches down the road, as one delivery skipper discovered. He learned the hard way how some production boatbuilders cope with putting a lid (the deck) on a very big box (a boat). The better the builder, the tighter the fit. More hurried builders over-trim bulkheads and some even allow them to float. And that is exactly what made life miserable for the delivery skipper and his crew.

As they beat to windward and their anchor locker filled, the water discovered the bad hull-to-deck fit and the builders less-than-careful tabbing. In effect, it was the exact opposite of how a collision or watertight bulkhead should be constructed, and the result was a leak that was nearly as threatening as a crack in the hull.

Lesson learned: If the boat you own-or the one you are about to buy-has an anchor well, check carefully and see how its sealed off from the rest of the boat. Also check sealed wire-run leads and all bulkhead penetrations.

Conclusion

By no means is this a condemnation of the concept of an anchor well. For coastal cruisers and offshore sailors, it can work, but its important to consider the points we’ve covered here. Every builder varies in their approach to locker design and construction, so give any boat you’re potentially buying close scrutiny to be sure the anchor locker has been well thought-out and well built. If you already own a boat, be sure it is up to the task at hand.

The contemporary anchor locker setup favors clear-deck convenience. This compromise can have some serious disadvantages. As with most things on sailboats, boat owners/buyers have to weigh the pros and cons and find a balance that meets their needs.

all water in the locker. Residual water evaporates, but it leaves the salt behind.

The brine combines with the sulfur-laden bottom residue, creating a galvanic

reaction and a puddle of rust. Even on this new boat, anchored only a few times,

water trapped in the anchor well has already becoming a chemistry experiment.

creating a watertight seal than the typical gasketed lids. In this case, however,

the chain fall is mere inches before the chain has to bend at a right angle as it

drops into the locker. Both chain stripping and castling will likely be an issue.

Anchor lockers are a convenience to coastal cruisers but no friend to offshore sailors. Passagemakers often forgo a deck-clearing locker for a belowdecks anchor-chain well. An angled spill pipe leads the anchor chain from the deck to the well, which often is under the forepeak and behind a watertight bulkhead. The setup not only eliminates the flooded-bow worries inherent with an on-deck locker, but it also moves the chain and anchors’ weight lower and further aft, where it should be to avoid hobby-horsing.

To keep water out of the belowdecks chain box, you first must keep water from pouring down the spill pipe. We have heard of numerous methods to seal the deck hole—from Silly Putty and duct tape to threaded brass caps and rags—and most of them work in most conditions. The holestopper methods PS contributors have found to be effective in even the heaviest of weather (when a boarding sea can create a fire-hose effect) include:

Teak plug: Sized to fit the deck hole and about 6 inches long, with an eye for attaching the chain to the bottom (after it’s removed from the anchor) and a fitting on top for pulling it out later (which may have to be done with a halyard). As the wood gets wet, it swells to seal the hole. PS contributors and circumnavigators Evans Starzinger and Beth Leonard use a Delrin plug in the same way, but they bed it with silicone before getting underway.

Closed-cell foam (from a cushion, Nerf ball, or the Forespar TruPlug): PS Technical Editor and bluewater sailor Ralph Naranjo suggests squeezing closed-cell foam “like a rubber rivet into the aperture.”

Other tried-and-proven methods include leaving the anchor on and spraying canned expanding foam insulation into the hole (this dislodges easily when the anchor is dropped); shoving a tennis ball into the chain-pipe (for a chain still attached to a bow anchor, split the ball half-way and pass the chain through it); cramming a rag into the hole and spraying foam insulation over it.

If like most of us you leave the chain on the gypsy of the windless the chain naturally is IN the hole To the chain box so completely sealing it is next to impossible BUT does it need to be? In my case The chain box never gets more water in it then the bilge pump can pump out so a drain from the chain box to a deeper bilge with a automatic pump takes care of the amount of water getting through the chain hole. In fact even when waves are coming over the bow little water gets down that hole. Then I would expect everyone has rope spliced on to the end of their chain rode (personally I have 100 feet of it. And it’s spliced NOT shackled because a chain shackle won’t fit through the whole nor will it fit in the gypsy when transition from the chain to rope. (Rarely ever exceed my anchor chain BUT if needed to anchor in a deep anchorage I have a additional 100feet of rope rode) the end of that rope has a eye splice and THAT is attached to a shackle attached to the backing plate of the windless. I used to use sections of foam pool noodle split around the chain to close up the hole but I found so little water actually entered in that hole. It wasn’t worth the effort. My windless also is not at the very bow like some ether and it takes some pretty big waves to get to the hole, ( the whole foredeck would have to go under to submerge the windless and and then stay submerged for enough water to over load my bilge pump.

now originally the factory setup was no windless and a very shallow anchor locker that might fit a small danforth anchor a short length of chain and 100-150 feet of rope rode. It drained well under the clipper bow BUT this is no longer my primary anchor @and the primary anchor chain is not stored there.

I have two such danforth anchors on board in addition to my primary mantis anchor one is store in the original anchor locker the other secured in the aft locker. With a extra length of mooring chain so I can make up multiple anchor setups. (Or if my primary anchor and chain rode get hung up somehow that I was forced to cut it free and loose my primary anchor I have two backups until I can get a new primary.

All in all a all chain rode (with a rope rode added to the end) and a windless mounted further back from the bow and directing the chain down to a anchor box low and further back then the immediate bow is by far a better setup then small on deck recessed anchor boxes ) but I guess when these designers designed these little on deck anchor stowage it was for those who’s boats are NOT left at anchor they day sail out of a marina and maybe anchor up at a beach for the day do some swimming the pull the anchor up and head back to their slip . They also stay at the marina when heavy seas anencephaly big waves are forecast. So the design is perfect for them but no offshore cruising boat if it was actually designed as one (or redesigned well) has much use for a shallow on deck anchor locker.