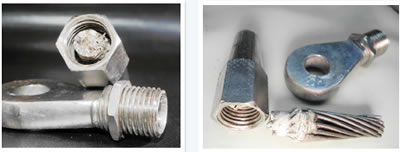

A couple of months ago, PS Technical Editor Ralph Naranjo disassembled a headstay that he had used aboard his Ericson 41 sloop, Wind Shadow, for nearly a decade. It was set up with Norseman fittings as terminals for 3/8-inch diameter, 1×19 stainless-steel wire that had supported a Harken roller-furling system. During disassembly, neither the wire nor the end fittings showed signs of corrosion or physical wear. And when the fittings themselves were taken apart-requiring heat to free the sealant in the terminal-the wire bundle was pristine and showed no sign of any slippage or corrosion.

Looking back at how he made up the terminals a decade earlier, Naranjo recalled some difficult decision making over commingling thread-lock (such as Loctite) and socket sealant. Good fortune prevailed, and what he settled on has obviously stood the test of time, not to mention sea-induced wear and tear.

Naranjo had used a viscous polyurethane sealant (3M 4000 UV is a good choice), rather than silicone and made a significant effort during the dry-fit stage to get some Loctite 242 on the male stainless-steel threads. During the initial tightening to form the wire over the head of the cone, the Loctite transferred itself to the female threads, and as soon as he had backed off and checked how the outer strands had evenly shaped around the cone, he loaded the socket and coated the wire with sealant-readying things for final assembly.

Threaded stainless-steel hardware under compression is prone to galling, a process that can, in effect, weld the threaded components together. In order to be absolutely sure this would not occur, Naranjo added more 242 Loctite, which also helped to keep the hardware from loosening. He also found that assembly took less torque than one might imagine, and he finished up each installation with a lot less vigor than you would use on an automotive lug nut. A couple of threads usually remained showing, and sealant oozed out of the upper end of each terminal.

Looking closely at the 10-year old hardware revealed no sign of deterioration from water intrusion. The geometry of the wires surrounding cones was just as it should be. Many riggers use silicone sealant as their preferred bedding compound for the interior of the terminal, but aboard Wind Shadow, polyurethane sealant worked well. Some pros use red Loctite 262 while others prefer blue 242; both seem to deliver the goods.

The polyurethane sealant 3M 4000 UV is also excellent, as it adheres better to metal than other sealants. We do not recommend 3M 5200, on the other hand, as it does not stick well to stainless steel.

Thank you Darrell and Ralph, impressive getting a review of the Norseman fitting after 10 years. Looks like careful assembly at the start is key.