Cheoy Lee Shipyards of Hong Kong has been a commercial builder since the early 1900s and is one of the first molders of fiberglass boats in Asia. Production of fiberglass boats began in the early 1960s and continues today, although the company—like many big yards around the world—has turned its focus toward commercial ships and the mega-yacht market. Looking at the line of 78- to 100-plus-foot yachts catering to Far East millionaires and billionaires, it is clear that any concerns about what would happen to Cheoy Lee when Hong Kong reverted to China were way off target.

Main offices of the venerable shipyard, which was building commercial craft for many years before the advent of fiberglass, are located on the Kowloon waterfront. As their operation grew, the company moved much of the actual construction facilities out to Lantao Island. It’s a barren place, virtually no trees, covered mostly with a brown grass. Workers are transported to and from each day by high-speed crew boats.

Cheoy Lee, like many Asian builders as well as custom U.S. and European builders, makes many of its own parts. We will never forget walking into one of the sheds on Lantao Island to find, at the edge of the shadow and door light, an old man delicately fairing a sand-casting for a propeller. He used simple hand tools, working, as best we could tell, entirely by eye. Though Asian boats still carry a fair amount of locally made stainless and bronze hardware, this trend began to change during the 1980s, when Western buyers, wary of cheap Asian knock-off accessories, began to demand name-brand portlights, water pumps, and the like.

An improved standard of living in Hong Kong and Taiwan raised labor rates to the point that it made sense to import essential hardware rather than hand-tool, and the elaborate woodwork you find in the early Cheoy Lees is no longer available at bargain rates in Asia. Back in the late 1960s and 1970s, however, Cheoy Lee enjoyed an enviable reputation for classic design and superior workmanship, even if some of the boats suffered from a few problems endemic to Asia, such as inappropriate use of plywood, poor electrical wiring practices, and the endemic teak-deck leaks that earned them the name “leaky teakies.”

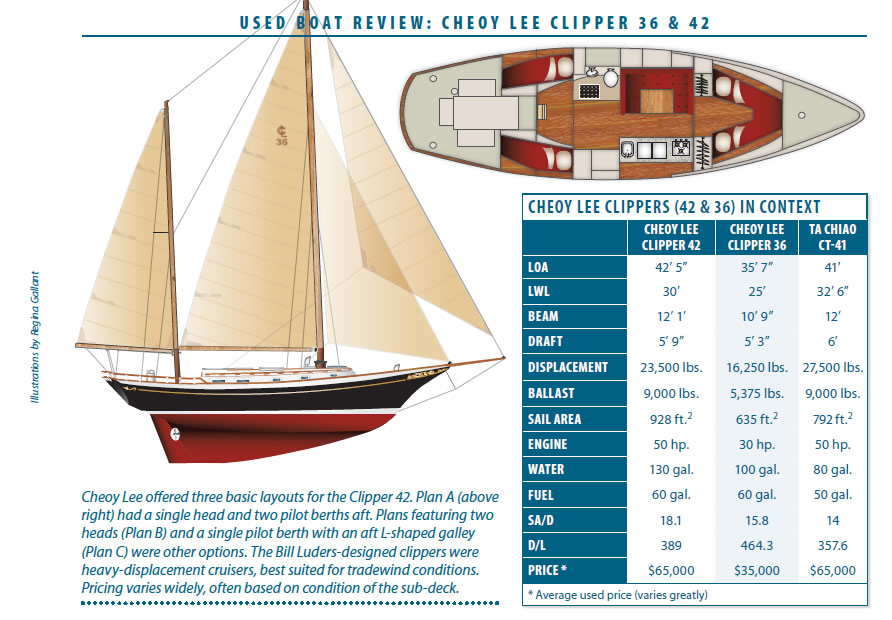

The Cheoy Lee Clipper 36 was built from 1969 to about 1988. The Clipper 42 was introduced in 1970. Eventually, both were replaced by the more contemporary designs of David Pedrick. We doubt that very many Clipper series boats were brought into the U.S. after the mid- or late 1980s.

THE DESIGN

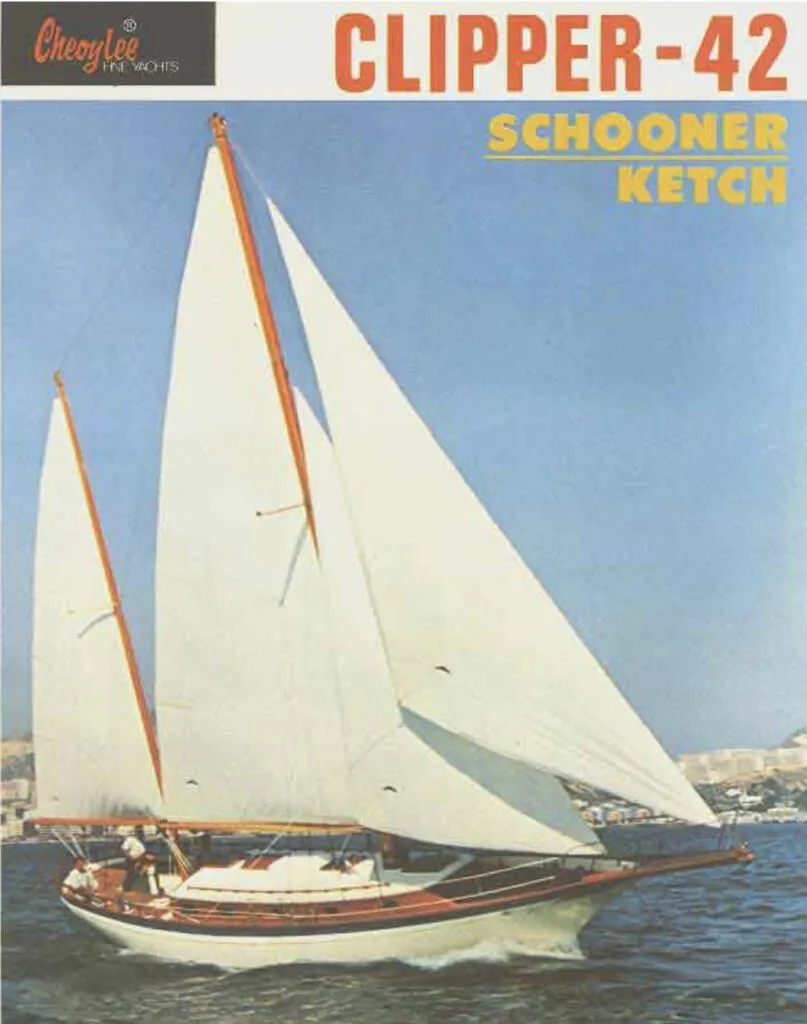

A.E. Bill Luders Jr. drew the lines for quite a few early Cheoy Lees, including the Clipper series and many of the Midshipman (early center-cockpit boats) and Offshore series. The Clipper 33, 36, and 42 were popular in large part because of their classic lines. In ways, they are reminiscent of L. Francis Herreshoff’s Ticonderoga. They are mostly ketch-rigged (actually cutter ketches with a Yankee, staysail, main, and mizzen), with bow sprits, wooden spars, graceful sheerlines, and moderate overhangs. Each has a full keel with attached rudder. Though we do not have all the drawings for the Clipper 36 and 42, their displacement/length ratios of 464 and 389 are very high, indicating that the garboards are quite slack and the bilges full. Or in other words, these are heavy-displacement boats with a very traditional Y-shape.

The numbers, however, are a bit deceiving because the sailing length will increase considerably as the boat heels.

The sail area/displacement ratio of the 36 ketch is 15.8, which is low to moderate. The 42 ketch has a more generous ratio of about 18. The divided sailplan is well suited to offshore cruising and will provide adequate power, especially on a reach. These boats would not be expected to excel either upwind or downwind. The 36 was available with a cutter rig, though we have no record of any in our files, and both the 36 and 42 could be ordered with a staysail schooner rig, of which we know at least a few.

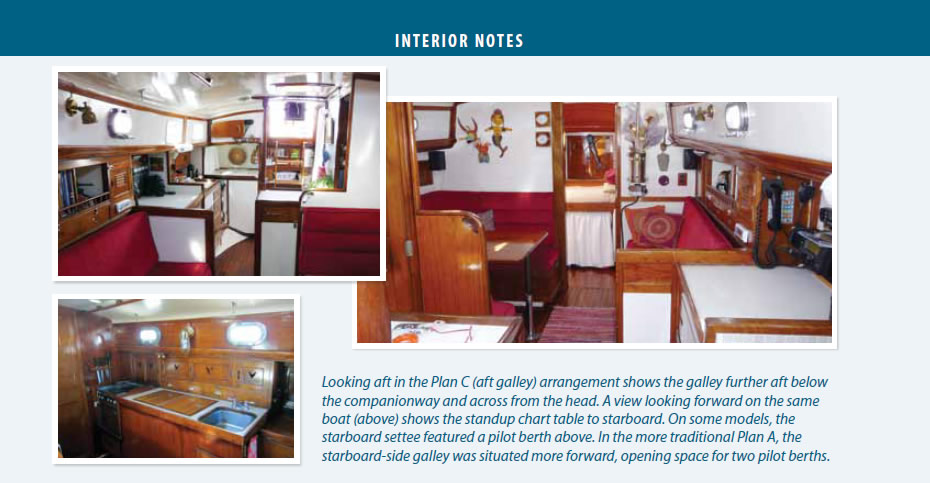

The underwater lines of the 48, for which we have the full designer drawings, are similar to that of the 36 and 42. The Clipper 48 has a traditional interior with V-berth, pullout settees and pilot berths in the saloon, and an aft stateroom with double and single berths. Several alternative layouts were available, including a U-shaped dinette in the saloon and a circular dinette forward.

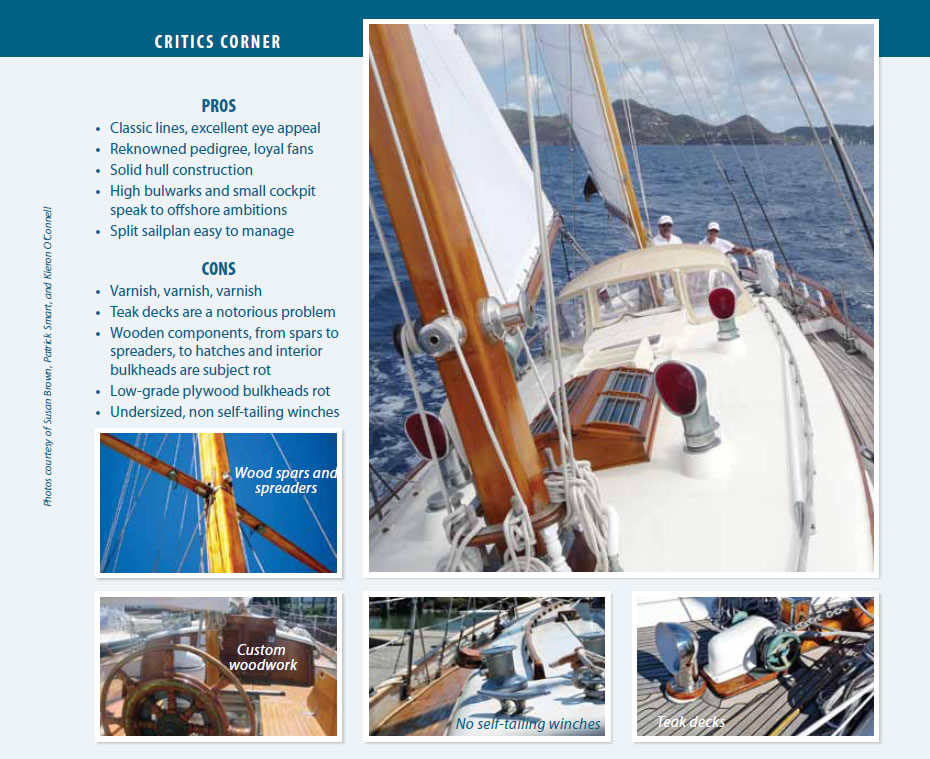

Photos courtesy of Susan Brown and Kieron O’Connell

CONSTRUCTION

Like most boats of this vintage, the Clipper 36 and 42 have solid fiberglass hulls. According to company literature, the thicknesses range from about 7/16-inch at the sheer to 1-inch at the keel. This is hefty. Unlike a number of other early fiberglass classics (such as the Mariner 31/32 or Black Watch 37), the Clippers had fiberglass decks, most with a teak overlay.

Henry Geerken, the owner of a 1969 model, told us that his deck was mahogany planking covered with fiberglass, then teak. He discovered this when he was having the deck planking removed. (As we have noted many times in previous articles, teak decks do not last forever, maybe 25 years, and replacement is very costly. Geerken paid $14,000 for a new fiberglass deck, which he said was less expensive than teak. In hot weather, he also found, this made the boat cooler inside.) Ballast is cast iron, externally fitted to the keel. Lead is preferable as it is denser, softer, and not subject to the corrosion that iron is. You’ll want to keep the iron keel coated with epoxy, with all the attendant prep work, including, but not limited to, sand- or bead-blasting to remove all traces of corrosion.

A number of owners have complained about the gelcoat, which one owner said was never up to par. Another said he had to paint his topsides after just three years. Geerken’s cored fiberglass rudder split, though the surveyor said it could be satisfactorily repaired by injecting epoxy resin.

Steering is via cable-quadrant, and on some boats, there was no provision for an emergency rudder. Before taking an ocean passage, you’d want to work out an emergency steering system.

The interior is all wood, and nicely done, which was the main reason for buying an Asian boat in the first place. An old brochure calls it a lavish teak interior. The owner of a 1981 model , however, said it was beautiful, but too much teak to varnish. In recent years, there has been a trend away from teak for just this reason. (Lower initial cost, lower weight, and brighter interiors are three other good reasons.)

Bulkheads are tabbed to the hull, which provides for a very strong structure. A 1994 survey of Geerken’s 1969 Clipper 36 showed the bonds to be intact. Other owners, however, complained about bulkheads made of non-marine grade plywood that was susceptible to rot.

Berths were foam rubber, covered with vinyl; if they haven’t been replaced yet, they should be. Countertops were Formica; sinks were stainless steel. The original toilet was the Wilcox-Crittenden Imperial, and the last time we checked, you could still find parts for this popular, well-made toilet.

Ventilation is provided by a teak and Plexiglas skylight, forward hatch, four cowl vents (five on the 42), and two Dorades. Skylights are notorious leakers and will have to be recaulked or rebuilt at some point. Although the original specs called for fixed ports, we have seen both fixed and opening ports on both models, usually high-quality bronze or stainless steel.

Cheoy Lee Clipper 36 and 42 are only rarely on the used boat market. We found these two CL Luders 36s. However, the Cheoy Lee owners association is very active and used Clippers come up occasionally.

Fuel and water tanks are made of fiberglass. Aluminum is a better choice for diesel, and water in a fiberglass tank tends to taste a little funny. Still, if properly made, fiberglass certainly is serviceable. Geerken’s surveyor did note that the copper fuel lines had unsupported runs, which could make them subject to vibration damage.

Geerken pointed out to us that the electrical system on his boat uses the positive as ground, which foiled his electrical trouble-shooting efforts until he figured it out.

Many original boats came with a wooden ladder that fit amidships, but these are often lost or deteriorate. Geerken bought an 8-foot one from Defender Industries.

Photo courtesy of Susan Brown

PERFORMANCE

As mentioned earlier, the Clipper cutter-ketches or schooners sail best on a reach, and then their speed will be more than adequate. Upwind and downwind, the boat will feel slow compared to lighter, fin-keel sloops. But speed is not the reason to buy one of these boats. They are, after all, capable offshore designs.

Readers rate seaworthiness as excellent, but stability less so. As one would expect from the narrow beam, Y-shaped hull, and heavy Sitka spruce spars, they are a bit tender initially, though stiffen up nicely once their shoulders are in the water. One reader said, “She looks after you.”

Balance was rated as above average by most owners. With the ketch rig, it should be possible to get the boat to steer itself with the wind on the beam or forward of it. One owner said, it has slight weather helm. “Trim sails, put wheel lock on, and let’s go! Some weather helm, of course, is desirable and necessary.

Geerken’s sail trim advice is to trim the Yankee first, staysail second, and main third; then ease the weather helm with the mizzen.

The main has roller-reefing rather than the jiffy reefing most often seen today. Roller reefing can work well up to about the first reef point, but it is unnecessarily complicated and can chafe the sails, so it makes sense to give up on this antiquated system and convert to simpler, more effective jiffy reefing.

Owner reports in our files indicate that the Clipper 36 was powered by either the Westerbeke 4-107 or Perkins 4-108 diesel engines, though some others we know had Atomic 4 gasoline engines. Both the Westerbeke and Perkins are excellent engines, but we prefer the Perkins. Owners of both said the engines were highly reliable, as we know from firsthand experience, but that accessibility is abominable, or in the words of one owner, “Zilch!” Among other things, checking/adjusting the stuffing box will not be easy.

Expect to make about six knots at 1600 rpm. Literature from Lion Yachts, the old East Coast distributor, indicates that the 42 came with the Perkins 4-108, though one owner had a 75-horsepower Volvo diesel. “Had 13 reasons for replacing after six years,” he wrote. He repowered with a Perkins 4-108, which he said wasn’t big enough, although many owners find it quite enough.

Full-keel boats with attached rudders and the propeller in an aperture do not tend to back down well, and the Clipper series is no exception.

CONCLUSION

Theres no denying that the classic look of the Cheoy Lee Clipper series is enough to make your heart flutter: That’s what a boat is suppose to look like! Indeed, some well-known personalities such as singer-songwriter Jimmy Buffet have succumbed to the Clipper’s siren song. Construction certainly was above average, with heavily laid hulls and fairly sound joinery.

Less noticeable are a small variety of potential problems stemming from the wooden spars, occasional flaws in metal work, and electrical work and components. One Clipper owner, for example, found that the stainless chainplates were secured with iron bolts and nuts, which corroded. Lazarette, hatch, and seat locker lids were sometimes made of plywood with insufficient fiberglass over it to seal out moisture. Previous owners may have upgraded or fixed some of these problems as they occurred. As with any boat, we’d ask the most persnickety surveyor to go over it with a fine-tooth comb. Because the interiors of these boats are quite complex, we suspect the list of repair jobs will be longer than usual. Regarding performance, the boat is deceptively quick on a reach, but due to its full keel and heavy displacement hull shape, it does not excel upwind or down.

Prices for early models represent a good value in today’s market. You might be able to pick up a 36 for less than $30,000, but carefully check the engine and teak decks as both are expensive to replace. You don’t buy a Cheoy Lee Clipper for performance or ease of maintenance. The 36 and 42 appeal to certain types of sailors, and you know who you are. Go in with your eyes open, ready to work (or pay), and you’ll have a boat to be proud of for many years to come.