Anyone who ventures farther away from a safe shore than their propulsion systems can carry them in a few minutes needs to have plans to deal with several “what if” situations. The hull-breach scenario is one of these, and although one of the worst, it can certainly be dealt with more effectively with some prior planning and cool thinking.

If your bow shears off, as some have on offshore multifulls in recent years, or your hull fractures or folds in half, like some America’s Cup boats have been known to do, there aren’t many options. You’ll notice that in those events, however, the unlucky sailors were saved either by watertight bulkheads and extremely skilled jury-riggers on board, or by cadres of support personnel in fast chase boats. Most of us have no such support at hand.

In the event of a puncture from the branch root of a semi-submerged log or the corner of a container, or a large crack from a broad impact on a Chesapeake telephone pole or 55-gallon drum, there are techniques that can be employed to get you and your vessel back in one piece. In the case of hull breach, fast recognition of the type and extent of the damage and knowing what’s at hand to deal with it are two crucial trains of thought that have to be followed almost simultaneously.

Many of the temporary repair options available where cracks and small holes are concerned, center around the use of underwater adhesives. These are a class of adhesives that possess the ability to be applied and cured underwater. In many cases, they’re used either to plug a crack or hole, or to apply a plate or film to the damaged area to quickly seal out the leaking water.

We decided to take a look at some of the commercially available repair kits and underwater adhesive systems that might be included in a hull damage kit. We were a bit surprised to find so few kits available that were specifically designed to perform hull breach repairs. It’s encouraging to think that the scenario is unlikely enough to suppress commercial interest in providing for the market. The one kit put together expressly for the purpose of emergency hull repair, the Kollision Kit, made in England, was out of stock and unattainable for this series of tests.

There are dozens if not hundreds of commercial epoxies used in different industries all over the world. Many, we’re sure, would work as well, if not better, than the ones tested here. For example, in “Hull Hole Damage Control” (page 24) Meade Gougeon mentions his shop material, G-5, as a good, sticky repair material for underwater use. The trouble is, most industrial building epoxies aren’t known to the public, and they aren’t for sale to sailors off the street who need less than a truckload of the stuff.

In any case, the separate materials we found and evaluated in this test can be purchased as the basis of a kit that could be assembled by any boatowner. Ten underwater epoxies were selected as samples for evaluation in hull repairs. All of the adhesives tested here are advertised and sold as underwater systems, although few specifically for underwater hull repair applications.

What We Looked At

It was our goal to present enough information here that a boatowner might make informed decisions with respect to what to carry and how to use it effectively in different situations. This requires a fairly well rounded set of information that need not be overly complex. With respect to mixing and application, we looked carefully at the physical characteristics of the adhesives and resins that were evaluated. These characteristics would be important to the user in the determination of what system might be used for different types of repair options. We looked at the ease of combining and mixing each product as well as its mixed viscosity, underwater tack and holding power. We also looked at handling time and cure speed underwater. As a final test, we looked at the relative bond strength of each system on aluminum, gelcoat, wet wood, and bare fiberglass after making bonds underwater.

Procedures

All data sheets and information supplied with each sample were carefully reviewed for specific instructions and details on how to use the adhesives and resins. Most of the epoxies combined at a ratio of one part base resin to one part hardener. The exceptions to this were Bio-Seal 258, Bio-Seal 192, and SS218.

Each system was used out of its container at room temperature. The two epoxy sticks (AquaMend and Quik Aluminum) that were tested are designed simply to be cut like a package of cookie dough. The hardener and epoxy components are pre-combined coaxially, one within the other. After the proper size charge is cut, they are simply kneaded together until fully mixed and then must be applied before they begin to cure. No measuring of components is required.

The MSI B001327 material is applied using a side-by-side syringe similar to the two-ton and five-minute epoxies you can find at your local hardware store. Simply depressing the plunger on the syringe dispenses a correctly metered shots of material that only needs mixing to be ready to use.

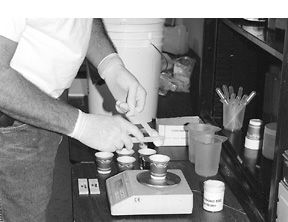

All other materials were metered at their recommended ratio using an Ohaus analytical balance. All materials were dispensed into and thoroughly mixed in a 50cc plastic beaker using a wooden tongue depressor. Most adhesive/hardener combinations were color-specific to provide a good visual indication of how well the components were mixed.

All of the substrates that were to be bonded were preconditioned underwater for 24 hours at 62 degrees F. Each substrate measured one inch in width by four inches in length by whatever thickness was used. The aluminum coupons were .0625″ thick (5086 grade). The wood coupons were oak, measuring approximately .25″ thick. The composite coupons were approximately .25″ thick and made with DCPD resin and fiberglass mat on the bare side and Cook Armorcoat on the gelcoat side. Both bare laminate and gelcoat surfaces were tested.

Each adhesive or resin system was applied to one side of the wet substrate underwater one minute after mixing. Observations were made with respect to the ease of spreading the material underwater and its ability to stay where it was placed. The second half of the substrate was then applied to the first, forming a one-square-inch overlap representing the bond. Each sample was gently squeezed until a small amount of adhesive flowed out of the joint (called “squeeze out”).

All bonds were checked every 5 minutes for the first half hour and then every 10 minutes for the next 1.5 hours to determine cure speed and green strength development while curing underwater. During this period, we also looked at the holding power of the wet adhesive to keep the bonded components together under the influence of gravity.

All bonds were allowed to sit for 24 hours underwater. They were then removed, dried, and broken by hand in a cleavage fashion to determine relative bond strength.

Prior to making bonds, a portion of each material was spread on a separate test board and placed in the water to cure. After cure, it was removed and checked for its degree of toughness. An empirical rating of poor, fair, good or excellent was applied to each observation where relevant. Actual measured values were used where applicable.

Discussion

In fairness, we must begin by stating that few of the products tested were developed specifically for hull repair applications; however, all materials tested were supplied as underwater repair systems for various different material classes or applications. It was our intention to see if their underwater capabilities could be extended to temporary hull repair.

We operated under the assumption that perhaps two general hull repair approaches might be used with adhesives. Both would require going over the side to get the job done, where flow and hydrostatic pressure will work in your favor and provide some clamping pressure to the plug or patch.

The first approach might be to cover the hole or crack with a flexible film or solid plate that would be held in position by the repair system until cured. The second might be to impregnate an expandable material or packing like a sponge or rag with the repair system material and force it into a crack or hole, thus sealing it and providing a solid patch after cure. For these reasons, both high- and low- viscosity systems were tested.

Only a few of the products tested were designed for the rapid cure one would want for doing these types of repair. In a breach situation, a fast curing product is very important. Cold water cannot be tolerated for very long by the repairer and a slow curing plate or film might fall off in any kind of surf or turbulent condition. Common duct tape works fairly well at holding such plates in place underwater and could be considered for such a use.

In the case of a thinner viscosity material, it’s best to wait for the material to begin to thicken prior to applying it in a patch situation. This improves its degree of tack and may help hold a patch plate in place better. In the midst of a hull-breach emergency, time is of the essence; however, a thinner-viscosity compound might be the correct choice for making the repair once things have calmed down a bit.

It’s also important to remember that the cure speed of most of these systems is listed for conditions at room temperature (23 degrees C). A reduction in temperature of 10 degrees C will double your working and cure times. Similarly, increasing temperature by 10 degrees C will cut the data sheet values in half. While most water temperatures rarely exceed the lower 80s, we know they can be considerably colder. A fast system will be required in colder waters, assuming that a speedy repair is urgent.

Conclusions

None of the faster systems, Bio-Fix 911, RayCrete, AquaMend, and Quik Aluminum was capable of developing good adhesion between the composite or the wet wood materials. On aluminum, only the Bio-Dur 911 developed a fair level of adhesion while the others returned very low performance.

In the plate adhesion scenario, the MSI B001327 product performed the best with respect to tacking specimens together. Although the product will run and sag out of the water (slowly), this was not observed underwater. Unfortunately, the product’s cure speed was very slow, eroding its practicality. We should note that although both bare FRP and gelcoat were tested, a patch would typically be applied to the gelcoat on the hull exterior.

The Armorcoat selected is known to present a very difficult bonding surface, but it represents the newer formulations of gelcoat commonly used by builders today. The same is true for the FRP resin: DCPD resins are very common in boats today and are notorious for being difficult to bond to.

We also note that in some cases it would be bottom paint that the plate would have to stick to, unless the paint could be scraped or removed before attempting the way of the repair.

The Bio-Fix 911 material did not possess good tack and hold capabilities, but if used with something to hold the plate in place (duct tape) it forms one of the quickest fair capacity bonds of all systems tested.

The epoxy stick materials were difficult to use in the plate-type repair due to the fact that a higher amount of clamping pressure is required to get them to tack to the repair surface and flow out of the joint. Only a small plate could be put in place with these materials.

As plugging materials, however, the two epoxy stick materials were the easiest to use since they’re not wet (fluid) systems but rather like dough. They functioned well to plug holes up to about an inch or so in width or diameter, simply by being mixed and pushed into the hole or crack. In a breach larger than that size, we suspect that water pressure would push the plug out. We also note their low bond performance on most materials and question the durability of a repair in turbulent conditions.

Bio-Fix 911, Bio-Gard 258, and Bio-Dur 561 make use of a Kevlar pulp fiber as both a reinforcement and thickening agent. This makes them a bit difficult to use to impregnate any type of wadding or foam, although Bio-Gard is still in the pourable viscosity range, along with its sister product, Bio-Seal 192, which contains no Kevlar. Cure speeds in Bio-Gard, Bio-Dur, and Bio-Seal were slow in developing green strength.

The same performance characteristics were shown by Hydrobond 500 and MSI B001327. Although they’re more paste-like materials, they worked well to impregnate fabrics that could be used as plugs. The MSI product is one of the few that is capable of repairing the Hypalon-type rubber used in some inflatable designs, although it again requires nearly a 48-hour cure to achieve this.

Our pick in this area would have to be the epoxy sticks, simply for their ease of use. Where large holes or cracks exist, the plate or film cover techniques would be best, and would require other systems.

In general, the RayCrete product had a poor cure underwater as well as poor adhesion and cohesive strength. This was the most highly filled system, perhaps using both microspheres and solids to provide for buoyancy control in the components through mix ratio. This product also required considerable mixing prior to use. We suspect that the sample we used may have overstretched its shelf life.

The best all-around adhesion was seen in the Bio-Dur 561 and Bio-Seal 258 materials, although neither would be considered excellent. The speed and versatility of the Bio-Fix 911 makes it good in most scenarios when used with other materials. Duct tape to fixture the repair is a good call in all cases. Both the MSI B001327 and Hydrobond 500 were slow but with fixturing would yield good repairs after a wait period.

Nothing performed well on wet wood. It’s important for epoxies to soak into the surface of wood to develop a good level of adhesion. Wet wood already possesses water in its surface that cannot be displaced by a high viscosity fluid like epoxy. Therefore adhesion opportunities are poor. Similarly, in the pursuit of good aluminum adhesion, both the external oxide layer and residual surface moisture are typically removed before a good bond can be formed. This is obviously not possible in such an application, which is perhaps why the results on aluminum were all generally poor.

It’s clear that there’s no way to be 100% prepared to deal with every contingency here. The many repair scenarios and conditions could be compared to sitting in an emergency room waiting for the next case to come through the door. All you can rely on are your experience, prior planning, and the equipment at hand. Each emergency is bound to be different.

If we had to pick one type of product, we’d keep some AquaMend epoxy sticks on board: They’re straightforward to work with, and are likely to cover a fairly wide range of problems. Aside from that, the choice comes down to whether you want setting speed (Bio-Fix 911) or tenacity of grip (MSI B001327). If there’s room, might as well carry a few options. After a season or two aboard, all should be replaced withfresh batches.

Contacts— AquaMend (epoxy stick) QuickAluminum (epoxy stick), Polymeric Systems Inc., 723 Wheatland St., Phoenixville, PA 19460-3394; 610/935-1170; www.polymerics.com. Bio-Fix 911, Bio-Dur 561, Bio-Gard 258, Bio-Seal 192, Progressive Epoxy Polymers, Inc., Frog Pond Hollow, 48 Wildwood Dr., Pittsfield, NH 03263-3406; 603/435-7199; www.epoxyproducts.com. Hydrobond 500, Polycaulk M-19, Superior Polymer Products, 25280 Renaissance Rd., Calumet, MI 49913; 906/337-3355; www.superiorpolymer.com. MSI 001327, Millworks Specialties International, 8004 California Ave., Fair Oaks, CA 95628; 916/961-7378; www.underwaterglue.com. RayCrete Ultimate, Valiant Technologies Inc. 175 Bosstick Blvd., Suite 107, San Marcos, CA 92069; 877/825-4268; www.val-tech.com.

Also With This Article

Click here to view “Value Guide: Underwater Repair Compounds.”