If you can’t position the jib clew exactly where you want it on all courses and in all weather, a barber hauler should be in your future, for even the most laid-back sailor. Here are some options.

If the jib has no or limited overlap, hauling the sheet inboard a few inches can be as simple as lightly tensioning the lazy sheet. A permanent in-hauler is typically rigged to a mast base turning block. If there is a lot of overlap, you can rig a line right across the cockpit to a spare winch, just for testing.

Options

Midships blocks offer multiple opportunities for testing. For reaching, a light block or even a carabiner on a fixed length strop attached to a mid-ships cleat can provide a solution. If some adjustability is required, the block can be attached to a length of line led under the cleat and back to a secondary winch; there will be more friction, but its only for reaching. If the line is a little longer, it will reach across the deck to the opposite sheet, where it can serve as an in-hauler. This creates tripping and chafe problems, of course, and is only temporary, for testing.

Snatch blocks make a removable barber haulers practical. This can make a lot of sense for spinnakers and reachers. We use the headsail barber haulers every day, so we always make these permanent. Loads are generally light, so use lightweight turning blocks to minimize friction.

We like low-friction rings for the sheet end. They’re light and there is less banging around. Carabiners make handy low-friction ring substitutes, but we only recommended them for testing, because they have a nasty habit of spontaneously clipping onto lifelines and other control lines.

A barber hauler that is intended to be adjusted under load will generally be led to a winch, but reaching outhaulers and twings for smaller boats can often be hand tensioned and led to a cam cleat, if you are willing to slack the sheet for a few moments while you make the adjustments. But since barber haulers are of greatest value when its blowing, make it sturdy.

I prefer positioning the basic sheeting system as far in as I will need it, so that I only have to haul outwards. However, new boats are coming out with systems that require hauling in and out, for all adjustments.

The simplest solution is to place a single low friction ring on the sheet, splice two tails to it, and lead one to a turning block at the mast base and the other to a turning block at the rail. A huge range of adjustment is possible.

Drew Frye is technical editor for Practical Sailor and author of Rigging Modern Anchors . He also blogs at his website www.blogspot.sail-delmarva.com.

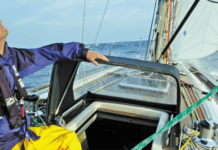

What is the antal part number for the deck mounted turning blocks pictured on the right of the image?