One of the great joys of sailing is the state of near nakedness (literal and figurative) to the wind, air, and sea-and the wisdom that comes with it. From that perspective, climate control seems antithetical to the sailors art. But being Practical Sailor (not Philosophical Sailor) we recognize that even the hardiest round-the-world racers seek temporary refuge dampness, cold, and heat. And for one looking to make the transition from the landlubbers life in temperate climates to full-time cruiser in the tropics, the idea of air-conditioning-despite its huge power demands-is alluring.

Today’s air-conditioning units are lighter and more power efficient than they were ten years ago, but they are still relatively expensive, regarded as luxury items on most boats. The expense of a professionally installed unit on a 35-footer can be as much as a new set sails.

Whenever you are plunking down that much money on a piece of gear, the first question that comes to mind is durability. How long will it last? So, in this, our first in a series of articles on climate control well look at types of air-conditioning and prospective life spans in the real world. (For those who are headed northbound and exploring heat options see Playing it Safe with LPG Heat, Practical Sailor, December 2015).

Photos by Drew Frye

What We Tested

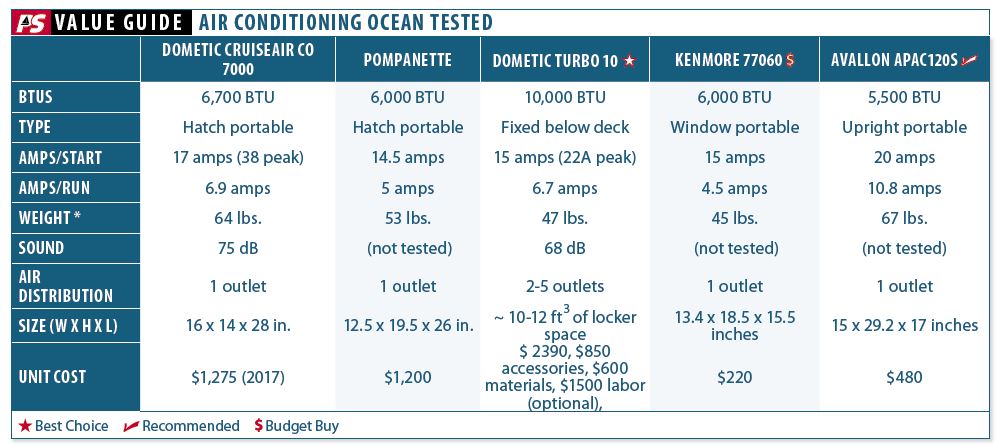

This long-term comparison focused on two products from Dometic, a world leader in this field-the Dometic CruiseAir 6,700 BTU portable air conditioner and the Dometic 10,000 BTU Turbo Air Conditioner. The units were chosen as representatives of two popular types of integral air conditioning units designed specifically for cruising boats, and were confident that most of our findings can be applied generically to each type. To put these two units into context, we compared their specifications, performance, and attributes to those of portable air-conditioners designed for home use but often used by live-aboard cruisers. A fourth type of air conditioner, the split gas system, which allows separate installation locations of the compressor (usually in the engine space) and the condenser coils and fans, will be looked at in a future article. A fifth type, the RV-type permanent roof-top (or hatch) mount is only really suitable for house boats, or boats that are permanently moored to a dock.

Both systems were installed on the same boat-a PDQ 32 – for an extended period. PS tester Drew Frye, who carried out the testing, has several years of experience using with each of these units on board. For comparison sake we included a portable window unit and a portable ducted air-conditioner, readily available at local home supply stores. Since we did not test the non-marine products, we relied on manufacturer supplied data for comparison.

How We Tested

Along with durability, noise and efficiency are the key concerns for most buyers. Using a calibrated decibel meter we took multiple noise readings from the two air conditioning units at a distance of one meter. We took current readings using a Fluke multimeter to compare energy efficiency and peak current loads. Finally, we observed any other notable differences in performance. The data is recorded in the adjacent tables.

Observations

Without question, portable units are cheaper than fixed units. The CruiseAir 6,700 BTU is no longer in production, but Pompanette makes a similar 6,000 BTU unit available from West Marine for about $1,200. Contrast this to $2,200 plus $1,200 in installation parts and materials for the Dometic Turbo 10000 BTU unit. Fitting the ducts and installing hardware for the Turbo can add two days to the DIY job. If you opt for a professional installation, this can raise the total cost to more than $5,000. The expense of a professionally installed permanent AC is a little less painful when you consider that the AC will increase the boats resale value-especially in warmer climates.

Is a DIY installation practical for a permanently installed AC? Sure, if you’re prepared to run wires and duct work and install through hulls and plumbing. The vendors say it can be done in an afternoon, and this is possible for skilled workman in an ideal situation. However, if the job requires complicated ductwork, allow a day for planning and three full days for installation. If you do decide to do your own installation, be careful not to compromise any structural bulkheads when cutting out passages for ductwork.

Follow the instructions rigorously. We have seen many botched installations, both amateur and professional, almost always because the installer did not follow the instructions. To save money on ductwork, buy the insulated duct and inlet/outlet fittings from a home improvement store or an RV store rather than from the manufacturer or a marine equipment supplier.

Floor mounted portables, connected to the outdoors via flexible ductwork, are another option. These are less expensive, only $250-$500 for comparable sizes, but they are still bulky, and they must be secured while the boat is underway. They are not a long-term solution for the mobile cruiser looking for maximum efficiency, but for the low budget cruiser stuck on the dock they are an affordable alternative to sweltering.

Avoid single-hose models. These draw cooling air only from inside, and exhaust hot air out through a duct. Since the air within the boat is often hotter and more humid than the outside air, this can reduce the cooling efficiency by as much as 50 percent.

A dual-hose unit recirculates indoor air and also draws air from outside, which improves efficiency significantly. Dual hose units are all greater than 10,000 BTUs. Some require a drain hose, while others evaporate the water into the hot air stream. Some can also operate as high capacity dehumidifiers.

Noise. A permanently installed air conditioner runs on seawater instead of air cooling, eliminating the often noisy cooling air fan required of all portable units. Testers installed the Dometic Turbos compressor and circulating fan inside one of the PDQs salon settees. With the settee seat cushions in place, the unit was very quiet-air hissed through the vents and the compressor emitted a low rumble.

The noise difference is considerable. Testers recorded 67 decibels for the installed Dometic Turbo vs. 75 decibels the smaller portable CruiseAir. Remember that a 10 decibel increase represents ten times the sound energy-so the difference is significant.

Tone. The sound pitch can also make a difference. The installed Turbo was lower in pitch and less intrusive than the CruiseAir. Quiet conversations were nearly impossible when the CruiseAir was running, while the noise of a permanently installed AC is can be nearly unnoticeable if installed correctly. Since the industry sound rating system is not directly comparable our own ratings for installed units, we did not rate the untested units for noise. Experience tells us that the standup and window portables will be closer to the hatch-mounted CruiseAir in terms of noise.

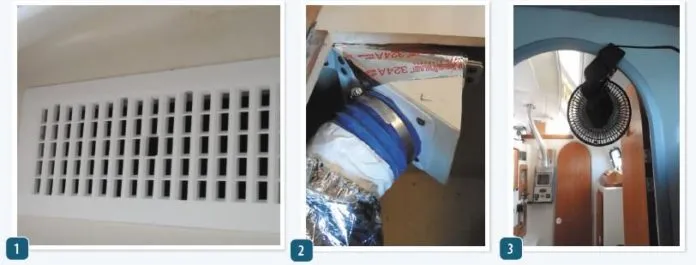

Distribution of cooling. With a portable air conditioner-any type-the person sitting next to it freezes. Distribution through the cabin can be aided by fans, but it will always be uneven. With installed air, vents take the air wherever you want it. However, it is important that area of the supply vent inlets falls within a recommended range. If a vent is too small efficiency suffers. If the inlet area is too big, the flow of cooler air is reduced.

The return volume must also meet the manufacturers minimum requirements, and the return inlet should not draw air from the bilge or engine space, which would not only spread odors and be inefficient, but also present a hazard.

Maintenance. The portable units require no maintenance, other than annual air filter cleaning. A permanent, central air conditioner requires regular raw water strainer cleaning, every 8 to 100 hours, depending on the amount of sea grass and nettles in the water. An external strainer is also required. This, too, needs to be checked for blockages, especially in high fouling areas.

Durability. The Dometic CruiseAir portable survived 18 years of seasonal use without complaint. Frye defied manufacture warnings, leaving it in place during many coastal passages on his catamaran, since it was too heavy to reasonably move and occupied too much space in the cabin. He lashed it down tightly, but that didn’t save it from spray and occasional green water. In the process of moving it, it took a few hard knocks. Eventually, the clamps on the leveling mechanism began to slip, but they were easily replaced with pins that were fabricated from fiberglass tent poles.

Weight. Excess weight is always a concern for sailors. The Pompanette 6,000 BTU unit weighs 53 pounds and the Dometic Turbo 10,000 BTU weighs 47 pounds-plus 17 pounds worth of installation parts (64 pounds total). The added weight of the installed unit is carried much lower, reducing pitching and lowering the center of gravity.

Storage Space. The compressor and condenser coils will occupy one small locker, and you’ll give up parts of other lockers for the duct work. This is the time for that house cleaning you’ve been putting off. Portable units require space when stowed for sailing, preferably where they are out of the way.

Power Requirements. The Pompanette 6,000 BTU portable draws 17 amps to start and 6.9 amps running. The Dometic Turbo, 10,000 BTU draws 14.5 amps to start and 6.7 amps running. It incorporates Dometics Smart Start capacitor and controller to reduce load spikes during start-up. The Avallon 12,000 draws a whopping 10.8 amps running, pressing the maximum safe running load of a 15 amp circuit. Clearly, the Dometic unit is the most efficient, and that translates not only into lower power bills, but also into reduced installation complexity. The Dometic, aided by the smart start controller is easily served by a 15-amp circuit, while the Avallon portable is bumping right up against the maximum.

Inconveniences. Carrying a 55-pound AC unit around the side decks, on-and-off the dock, and down below can be dangerous. Even with two people, getting it down through the companionway is still tricky. What is the cost of a single serious injury? When the unit is stored below for a foul weather passage, it must be well secured and takes up valuable space. If left in the deck hatch during fair-weather sailing, it blocks the view, blocks natural ventilation through the hatch, and snags every sheet that comes near it.

No matter how carefully fitted, hatch units leak rainwater during squalls. Because the close proximity to humid air where they fit through the hatch, most drip condensation. Window units and dual hose units also have concerns.

The only inconveniences of installed AC are opening the seacock and cleaning the raw water strainer. Locate both so they are easy to access. The strainer should have valves on both sides to reduce water spillage. The seacock should be closed when not in use (safety) and for 24 hours every few weeks. Closing the seacock for 24 hours prevents marine growth by eliminating oxygen and by allowing the concentration of copper ions in the water, leached from the copper coil, to reach preventative levels.

Hatch Mounted Units

A step above home store window units, hatch mounted units are a good temporary solution for dockside living while your moored to terra firma doing boat work or rebuilding the cruising kitty.

Dometic CruiseAir 6,700 BTU

We knocked this one around, it took green water right over the top several times (not while running), and though noisy and annoying to have on deck, it just kept running. I doubt many users abused theirs any more, although they may have more hours on them.

Bottom line: Recommended as a second-hand purchase.

Pompanette 6000

Very similar in size and weight to the CruiseAir, we’ve observed them on other boats but not studied them in depth. Those users we interviewed reported zero mechanical problems.

Bottom Line: Consider saving up for installed air.

Installed Air Conditioning

This is the option best suited for long-term cruising, because all of the critical components remain below decks protected from the elements. This feature is especially important for saltwater sailors. The premature failures with installed air systems that we know of stem from installation shortcomings, usually in the raw water suction design.

High intake loops that collect air result in unreliable operation. Oversized water pumps cause premature wear on the coil-bigger is not better in this case. Stray current can eat the cooling coil on the inside, and water leaks can drip seawater on the cooling coil, rotting it from the outside. Low voltage due to undersized wire or poor connections can strain the compressor. Properly installed, the unit should be as reliable and durable as a shore-based unit.

Dometic Turbo DTU 10 10,000 BTU

Dometic dominates this field with several lines of air conditioners to meet specific needs. Its smallest unit is the 3,500 BTU Cuddy, we opted for the 10,000 DTU 10 model.

This unit is quiet and efficient. Although the installation is time-consuming, the several days of boat yoga are well worth it. The very low power draw is a big bonus, allowing us to stay at marinas with modest power supplies.

A DIY installation requires good power tool skills and common sense (see aforementioned caution about penetrating structural bulkheads). It will likely require several days of steady work, or you can pay a contractor $1,000-$2,800, depending on the complexity of the installation and location of your boat.

Bottom line: Installed air is certainly the Best Choice, if you have either the DIY skills to do it right, or the dollars to hire someone.

Portable Uprights

There are dozens of brands of upright, dual hose-air conditioners. Friedrich is one brand that tested well with Consumer Reports, but their test field was limited. Our advice if you go this route is to compare warranty coverage and buy from a reputable supplier.

Avallon APAC120S

The advantage of caster-mounted units is that, unlike hatch mounted portables, you don’t have to lug them above and below decks. When you get the urge to sail they can be wheeled into a corner and secured, although they still eat up space. They are generally very quiet. Because they use a different BTU scale, a 12,000 BTU unit is closer to 5,500 BTU.

Finally, although they claim to evaporate all of the condensate back into the hot air exhaust, we still observed a few ounces of condensate on the most humid days. There is a pan with a sensor-remember to check it daily.

Bottom line: If you need quick AC for summer, this is a good solution while you make up your mind.

Window Units

Window units are clearly the shoestring sailors choice. Look for familiar brand names with good warranty coverage. Most today come with a remote control, which comes in handy.

Kenmore 10,000 BTU (#77060)

A dime a dozen, these are a cheap solution for the boat that spends a lot of time at the dock. We’ve seen them installed in companionway hatches using modified hatch boards, and over deck hatches, adapted to fit using some manner of home-made carpentry.

The former is more compatible with the design since the faceplate is meant to be in the room. There is also a YouTube video showing on how to modify one of these to operate below decks (although it requires quite a bit of metalwork).

Costing as little as $120 on sale, these can be the bargain solution for a small boat in a warm climate. Stowability and durability-especially in a marine environment-are the biggest drawbacks.

Bottom Line: A window unit can be a cheap, short-term solution while you make up your mind.

Conclusions

Portable air conditioning units can be durable and reliable, but they are inconvenient. Installed air conditioning adds considerable expense, particularly if professionally installed, but there is some recovery in increased resale value if properly done.

Generally these units are brought into service when the boat is dockside for long periods of time. If you are on the move between marinas – the stow and set-up routine with a portable can get tedious. But if you are held captive in one spot by circumstances and need some relief from the heat and stillness-a window mount or upright dual-hose will civilize your summer.

Stay tuned as we dive deeper into the world of compressors and coils and various options among split-gas systems.

Portable air conditioner can meet the needs of a casual cruiser, but long-term cruisers in tropical climates, especially those with boats greater than 40 feet long, will be better served by installed systems.

Nearly all marine air-conditioning problems can be partly traced to poor installation. A key step is to create a schematic that maps out the wiring, plumbing, ducts, and vents. Due to the potential fire risk with these systems, if you have doubts about wiring or fuses, you should consult an electrician. Although you don’t need to be an expert to succeed with a DIY installationit helps if you are a jack of all trades. And you need to do your homework.

1. A Fein Multimaster simplifies cutting in close quarters. Be careful not to compromise structural bulkheads or liners.

2. Measure twice, cut once. An inlet vent, mounted low in the main saloon fits snugly in its cutout.

3. We fabricated some of the plenums, transitions, and elbows, others were meant for use with clothes driers.

4. An above-the-waterline loop in the cooling water outlet (white hose) prevents backflow into a heeled boat.

5. Glue-on studs are a big help if you cannot through-bolt. These studs are from Duckworks. Weld Mount is another source. (See “Glue-on Fasteners” PS July 2017).

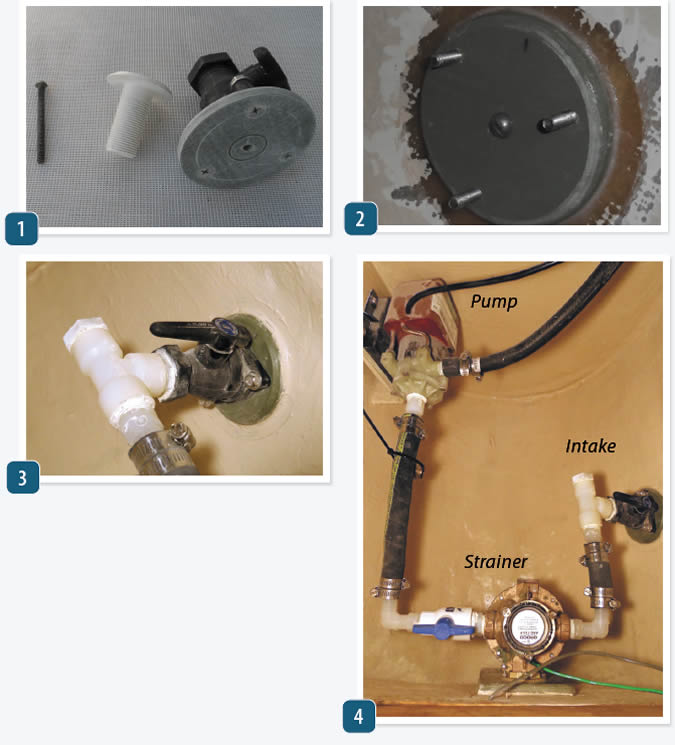

Properly plumbing the AC system is one of the most important installation tasks, not only from a functional standpoint, but also safety. In order to meet the American Boat and Yacht Standards for through hulls, the seacock needs to be able to withstand 500 pounds of static force for 30 seconds. This typically calls for a flanged base that is supported with screws or through-bolts. A backing plate that incorporates studs is one of the most sensible ways to meet the standard because it avoids the need for additional holes in the hull.

1. The home-made backing plate assembly is tested before gluing, from left: long screw used for clamping during gluing, UL certified Marelon through-hull, the assembled seacock and backing plate.

2. The backing plate with studs is clamped in place as epoxy glue cures.

3. A t-connector simplifies draining for winterizing, ensuring no low spots.

4. The water should rise smoothly from intake, through the strainer, to the pump. If any air pockets exist, the pump will not prime after a short peried of sailing (waves drive air into the pipes and the pump cavitates).

One suggestion, if you are using your AC system in places like Florida – include provisions to flush the piping. This includes connections from the seacock to the thru-hull, with connectors that are easy to get to and install. plus valves, if you have more than one unit on the boat. You will have to periodically use Barnacle Buster to clean out the pipes, and this is best done in recirc mode with a 5 gallon bucket. Also, think about installing a strainer that will accept a pool-cleaner chlorine tablet (or a sizeable piece of a tablet), to keep the piping clean.

Here, this is really useful comment, many thanks!

I am sorry but this article does not help. You should have tested same type of ac across different brands. But here, you are comparing apples to oranges….

Thank you for this article. Very encouraging in a safe manner.

We have a 1998 Beneteau Oceanis 321. We bought the boat in 2015. The first owner installed a Mermaid M6 6,500 BTU air conditioner shortly after he bought the boat. It has a heat cycle. It is designed to cool 550 cubic feet. We keep the boat on Lake Erie and sail six months a year. It works very well. No major repairs. The only repairs have been that we have had to replace the water pump in 2016 and 2022 due to wear and tear on the impeller.

We use the heat cycle in the spring and the fall. We leave it on most of the time at our dock. It keeps the humidity down in the boat. We have two effective 12v fans that we can run when we are not on shore power. We run it off 15 amp, 115 volt shore power.

I have experience as a yacht broker.

I agree with the advice in your article. I would add the following suggestions,

1. If at all possible buy a sailboat with factory A/C. The installation should be neater and easier to maintain. As the article states, most faults are with the installation. The yard who installed ours did a good job but I have seen many others that are less than seamanlike.

2. If installing an A/C unit, ensure you have an easy way to bleed air out of the water inlet plumbing to the pump. We have to bleed the system every spring after winter haulout. It is a pain in our boat. There are self priming pumps available but they are two to three times more expensive.

3. If installing an A/C unit, ensure you have a relatively easy way to clean the inlet water filter strainer. We have to clean the strainer about once a month in the summer. It is a pain on our boat.

4. If you are installing an A/C unit, ensure you install effective sound proofing. Ours is a bit more noisy than the factory A/C units I have experience with.

We have a Swallow Craft Swift 33 sailboat. It is a very large capacity 33′ boat. After almost a year of exploring options for AC we put in an overhead RV unit in the main cabin overhead hatch. One season in Florida and so far, we are very pleased. The unit is a Houghton B3500. It is low profile with 13,000 BTUs of cooling and 12,000 BTUs of heat. We just could not afford the lazarette space for a built in.