Designers of boat anchors deal in a handful of variables. The holding capacity of an anchor derives from its fluke, particularly the flukes size, shape, and the angle it makes with the shank. Other parts of the anchor-shank, roll bar, and stock-allow the fluke to set and hold as the designer intended. Based on the shapes and relationships between these components, an anchor fits into one of several broad categories: fluke (Danforth, Fortress, Manson Racer), plow (CQR, Delta, Kobra, SARCA Excel), claw (Bruce, Lewmar Claw, Manson Ray, Super Max), or fisherman (Luke).

A relatively new addition to these categories is the scoop, so named because the angles of the flukes are convex. Examples of scoop-type anchors include Spade, Rocna, Manson Supreme, Ultra, and Mantus. Well devote our closest attention in this article to the scoop category.

Note that fluke has two meanings: first, as an entire design category; second, on any anchor, the part that does the job of digging into the seabed. The simplest fluke is a flat plate, as youll find on a Danforth or Bugel. But relying only on a plate introduces other design puzzles. What happens if the anchor lands upside down on the seabed? Will the anchor fit on a bow roller? Will the fluke and shank be strong enough? And how much will it cost? Often, changing one variable affects two or three others.

Working the Angles

Though they look very different, many anchors of different types-CQR, Fortress, and Rocna, for example-hold surprising similarities. One similarity is the fluke-shank angle (also called simply the fluke angle): the angle the fluke makes relative to the shank (or, in the case of a curved or jointed shaft, the shanks load path). Another similarity is in the penetration angle: the angle the bottom of the fluke makes with the seabed when it lies still (sometimes tilted on its side) before setting; this helps determine whether the anchor initially sets. Finally, theres the setting angle: the angle the fluke makes with the seabed when the anchor is actually holding. This angle determines whether the anchor sets and holds well.

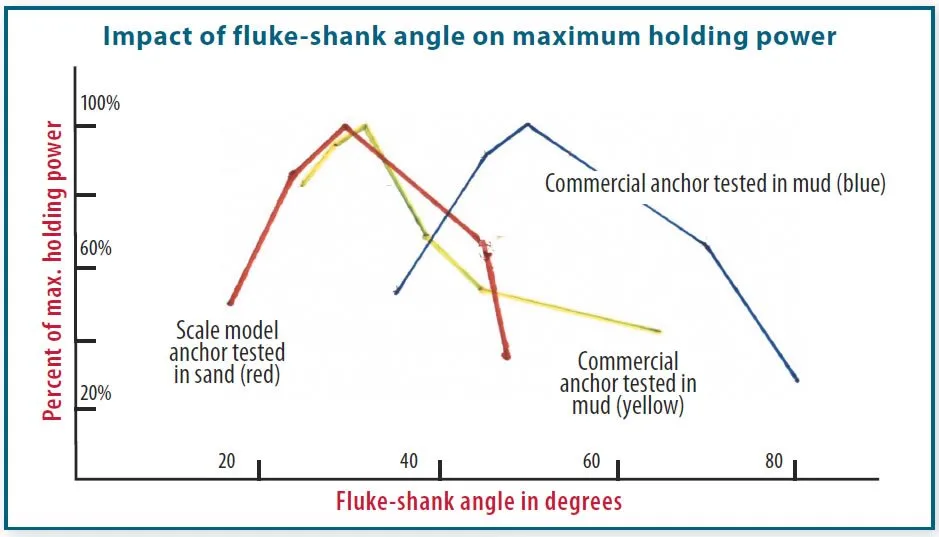

Fluke angles have been studied extensively, first by the British and U.S. navies, and more recently by the oil industry. The results are well known, but the recommendations differ according to the seabed. However, all researchers agree that comparing an anchors setting and holding ability purely by geometry can lead us astray-particularly when the angle differences are small. Empirical testing is required. Thus, the following report is simply laying the groundwork for future studies. It is not meant to single out any particular anchor. We hope this preliminary article will help PS readers better understand how their own anchors function, how to optimize the anchors holding ability, and how many of the tests appearing online can offer only a partial picture of anchor performance.

Last winter (see Small Anchor Reset Tests, PS February 2013), we reported that in thin mud an anchor with a fluke angle of around 45 degrees will outperform an identical anchor with its fluke angle set at 30 degrees. But a more viscous sand seabed is entirely different, and research demonstrates the ideal fluke angle for a typical sand bottom is around 30 degrees. Most scoop style anchors have fluke-shank angles of about 30 degrees-although how each maker measures the precise angle varies, and determining the exact angle can be complicated by angles, curves, or joints in the fluke and shank.

Recognizing that different bottoms may require different fluke-shank angles, some anchor designs allow the owner to change this angle. Fortress and the Super Max are two anchors that allow the owner to increase the fluke angle so that anchor can be adapted to suit either sand or thin muds. These are exceptional designs, yielding better than average results in mud (see our reports in 2006, Anchors for Muck for Under 200 Bucks, PS February, 2006; and Soft Mud Anchors for $200 and Up, PS April 2006).

Penetration Angles

Seemingly small changes to the details and geometry of the anchor that don’t significantly alter the fluke-shank angle can affect the penetration angle. The toe of the anchor (the point that digs in) is critical. If the toe does not dig in, the anchor will not set. Older designs like the CQR and Delta have cone-shaped toes that have trouble penetrating harder bottoms. In some anchors-CQR, Delta, and Spade-this deficiency was countered by adding weight (ballast) to move the center of gravity toward the toe. Recently, though, the use of stronger, harder metals has made possible the sharper toes we find in the SARCA Excel, Mantus, and Fortress. Toe design also helps, and the turned-down toe of the Ultra and Excel help engage the seabed.

We have quantitative measured the penetration angle of anchors of different types-Fortress, Excel, Spade, Manson Supreme-and found that 60 degrees is a fairly consistent angle for the initial plunge into a sand seabed.

How an anchor first engages a particular seabed can have a big impact on its final setting angle. Although the following description of the setting process can vary greatly according to seabed, it nevertheless offers a useful summary.

Penetration Into setting Angle

As load increases, the static anchor self rights from its tilted position on the seabed, re-orienting itself such that anchor is balanced and sitting on an even keel, one might say. As the fluke rotates and balances, its attitude from that initial penetration angle changes. This is where the anchors center of gravity can come into play. Depending on the composition of the bottom, if the angle is too steep, the anchor can potentially trip on the toe and drag; too shallow, and the anchor could skim the seabed surface like a cheese slicer.

As the anchor dives deeper, there is increasing resistance to burial. Gradually, the chain rode buries and introduces upward tension on the chain (some big-ship designs reduce this resistance by using cable instead of chain; see Anchor Rode Report, PS February 2014). The combined resistance of the shank, roll bar, and chain can cause the angle of penetration to lessen. Under extreme loads, the fluke will reach an attitude where it is nearly horizontal; this, in effect, is the anchors point of ultimate holding ability. Any additional load will cause the anchor to drag, or even begin to surface.

Soft mud seabed. Poor visibility has prevented our testers from accurately measure setting angles in murky seabeds. However, based on available studies, we think it is safe to assume that the optimum setting angle of 30 degrees (in clean sand) increases in mud, to about 45 degrees. Tests with identical designs set at different fluke angles supports the assumption an anchor with a greater fluke-shank angle holds better in soft mud.

Hard seabeds. Research of commercial anchors demonstrates that very hard seabeds require different characteristics. Sharp toes help. A narrower setting angle also helps. If the angle is too high in a hard seabed, the anchor simply trips up-and drags. Anchors that grab quickly in hard bottoms are popular among fisherman, and they can be useful to sailors in an emergency-losing an engine on a lee shore for example.

Modern Anchors in theory

These setting characteristics are easily observed with modern anchors: Spade, Fortress, Excel, Mantus, Rocna, Manson Supreme, and others. They all engage the seabed exceptionally quickly and develop hold rapidly. A modern anchor will often fully set within the length of the shank. Such older anchors as CQR, Bruce, and Delta often require more patience and skill to set.

In our view, it would be very difficult for the average boater to tell the difference between a similarly sized Spade, Excel, Manson Supreme, Fortress, Mantus, or Rocna anchor when set in a sand bottom in normal conditions. However, subtle design differences can matter in peripheral seabeds: mud, cobbles, weed-and under extreme loads.

Most of these modern anchors in a 35-pound size (less weight for an aluminum Fortress or alloy Spade or Excel) when tested in sand will all achieve a hold of approximately 4,000 pounds. This is the anchor a 35-foot boat with a 20-horsepower engine might use. If set correctly, the older-style anchor (CQR, Delta, Bruce) of the same weight will develop around 2,000 pounds of hold. Even the lesser number is plenty of hold for most conditions and high enough that you might need a trip line for easy retrieval. It is only when conditions deteriorate and the boat pitches and yaws that the 2,000-plus pound holding power of the newer-style anchors is required.

A very rough rule of thumb for engine performance is that for every 10 horsepower (assuming a reasonably efficient propeller) a boat can develop a rode tension of 225 pounds per 10 horsepower. So the 35-foot boat with 20-horsepower engine can set an anchor to 450 pounds of hold-far below the anchors ultimate holding potential. In other words, you can’t fully set an anchor, nor test its holding capacity by engine alone-the sea and wind is the true test. This is one reason why a real world test is so hard to simulate on YouTube. A four-wheel drive vehicle on a hard mud tidal flat can not replicate performance at sea.

Modern Designs: Quick Setters

By actually observing underwater how the anchors set and perform, weve noticed some anchors set quickly, but do not set as deeply as others. Based on our own testing and published videos, the setting angles of some scoop anchors, appear to have relatively shallower sets in some conditions. The observations are preliminary, and based mostly on third party videos and images. Some of these videos are used in advertising, or appear to made by individuals linked to one or more manufacturers. Others are carried out by sailors like Steve Goodwin who want to satisfy their own curiosity. (You can see Goodwin’s videos illustrating short scope anchor performance here: https://goo.gl/V24zjr).

Although the volume of photos and videos we’ve reviewed appear to support our own field observations regarding setting angles, we recognize that this is not enough evidence to make definitive conclusions on setting and holding ability. The differences in bottom type lead to a wide range of results, and the angle of pull (controlled through scope and load during setting) can also affect setting ability. More testing is needed, and it is important that future tests replicate identical conditions for all anchors. Measurements need to be made in situ, since it is difficult to measure the angle from an image.

If you’d like to share your own observations with Practical Sailor, the method we have used thus far to compare setting angles in photos and videos is relatively easy to replicate with your own or another anchor. You can examine any underwater photo of the partially set anchor in a sand bottom. The key points used to determine orientation are the shackle, and the corners in the shank and heel. By recreating the orientation on dry land, you can measure setting angle (see photos). Weve also done our own in situ measuring on a variety of anchors.

In hard sand, our testers Spade and Excel anchors have repeatedly set at an angle of 30 degrees to the seabed, sometimes much higher. He has also seen the Rocna consistently develop setting angles greater than 30 degrees in sand. However, images and videos that our testers dug up (pun intended) for this article show various scoop-style anchors setting at angles less than 20 degrees, in which case, the ultimate holding ability would be measurably compromised. Some of these images and videos appear to be staged to favor particular anchors, but they sometimes do the opposite, reveal potential weaknesses.

In several photos and videos our tester noticed scoop-style anchors setting at fairly small setting angles-as small as 17 degrees. When we contacted one of these manufacturers, Mantus, regarding this, they disagreed with our measurements and directed us to videos showing the Mantus and other anchors setting at similar angles in sand. One video (see: goo.gl/lZfWwZ) indicates a 4:1 scope on all rope rode, something you never see on a sailboat. (Other images and videos shared by Mantus showed more typical, all chain scenarios.) The many questions raised by these types of YouTube tests, were among the factors that prompted this study. In particularly, we were intrigued by emphasis on quick setting that these videos seem to demonstrate.

Greg Kutsen, owner of Mantus anchors, described the goal of his design. Mantus anchor is designed to maximize the likelihood of the anchor to set on every deployment even in hard and/or challenging bottoms, he said. We consider setting ability, a critical characteristic of a cruising anchor, while performance of the Mantus Anchor setting/holding in softer bottoms is similar to other scoop style anchors. We believe when sized appropriatly Mantus Anchor is a solid choice for a primary cruising anchor.

Ned Wood of Manson emphasized that any anchor design involves a trade-offs: A quality anchor manufacturer will balance the multiple characteristics of an anchor. . . The setting speed of an anchor which boaters rely on to allow their anchor to dig in first time, must be balanced against the ultimate holding power which is the function of an anchor . . . having an anchor that sets well, but simply doesn’t have ultimate holding means a manufacturer will overly promote setting speed to be what customers should seek.

It is important to note that the Mantus anchor has performed adequately in two tests we have covered, and several cruising boats reported weathering Hurricane Matthew on Mantus anchors. In a 2014 test conducted in soft mud organized by competitor Fortress Anchors (see Anchoring in Squishy Bottoms, PS February 2015), the Mantus performed ahead of CQR, Delta, Lewmar Claw, Rocna, and Spade. And in our dinghy anchor test, a two-pound Mantus held up to 160 pounds in sand (see Dinghy Anchors: Big Anchor Tech Scaled Down, PS December 2015). However, the results for the soft mud test (less than 700 pounds of holding power) were below what wed require for a working anchor of this size. And deducing the holding power of a full-sized anchor based solely on performance of a 2-pound anchor can lead to inaccurate conclusions.

In our view, more independent testing of ultimate holding capacity for these new style anchors in typical sand or clay (layered soil) environment is needed. Such a test would help determine if designs that tout short-scope, quick-setting ability in harder bottoms are just as effective in ultimate holding power in sand or layered-soil bottoms. Until we collect this data, the following observations, based partly on the research of Bob Taylor, a noted expert on anchoring, are salient.

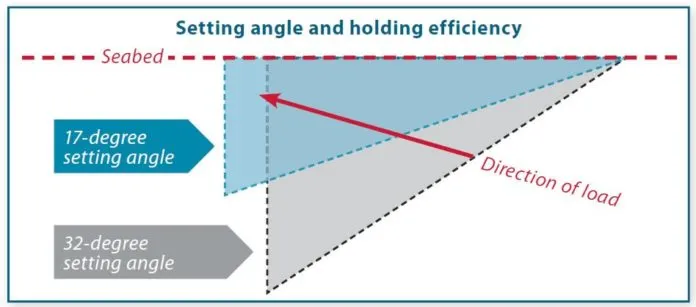

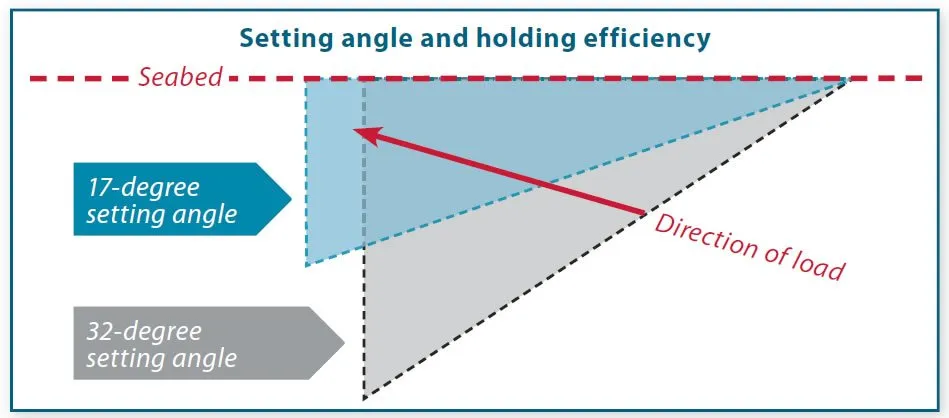

A fluke that sets at an angle that is 17 degrees relative to the seabed can penetrate the soil quickly, especially in a hard bottom, but the effective surface area of an anchor set at 17 degrees relative to the seabed will offer less holding ability than the same anchor set at 32 degrees (see illustration).

A chief advantage of a steeper setting angle is that it provides more effective surface area engaging the material in the seabed. In short, it digs in more. Once an anchor is set, the effective area of the anchor fluke and the depth that it buries, not weight, decides holding. In fact, a much smaller anchor that plunges deeper can often hold more than a larger, heavier anchor that does not dig in. (An anchor that is too deep raises other issues, such as the challenge of retrieval.)

In real life we don’t ever want to test our anchors ultimate holding capacity, but that can happen, particularly in marginal seabeds. An anchor for overnighting will offer a larger safety margin, compensating for marginal seabeds, yawing, pitching, and operator error. An anchor with a shallow setting angle of less than 20 degrees might make a great lunch hook, but it could reduce the safety margin in a big blow.

Another key factor is that deeper layers of the sea surface tend to be firmer. An anchor that penetrates and sets at an angle of 30 degrees or greater will dig into soil that offers greater holding power, while a shallow setting anchor might drag through looser soil.

Finally, as anchors dive, their setting angle decreases due to the increased drag of peripheral components: shank, roll bar, shackle, swivel, and chain. All of these components resist being buried. Eventually the sum of the resistances are simply too great, and the anchor will reach its ultimate holding capacity. When it reaches ultimate hold, the anchor fluke is approximately horizontal. Obviously, an anchor that starts setting with its fluke at an angle of less than 20 degrees to the seafloor could reach its maximum set more quickly as the shank and other components increase their resistance.

Conclusion

More research is required to determine how significantly a shallow burying angle impacts holding ability, whether this behavior is peculiar to specific designs, and what the sailor can do when setting the anchor to improve holding. Consumers need to be aware that all anchors represent a compromise: an anchor that grabs quickly in a hard bottom is not necessarily the best for a sailboat bracing for a storm in sandy cove, and a soft mud anchor that doesn’t do well in veer tests wont be best when a big wind shift is coming. A good anchoring arsenal on a cruising boat will include at least three anchors-two on the bow suited the bottoms youre likely to encounter, and a reliable kedge ready to deploy.

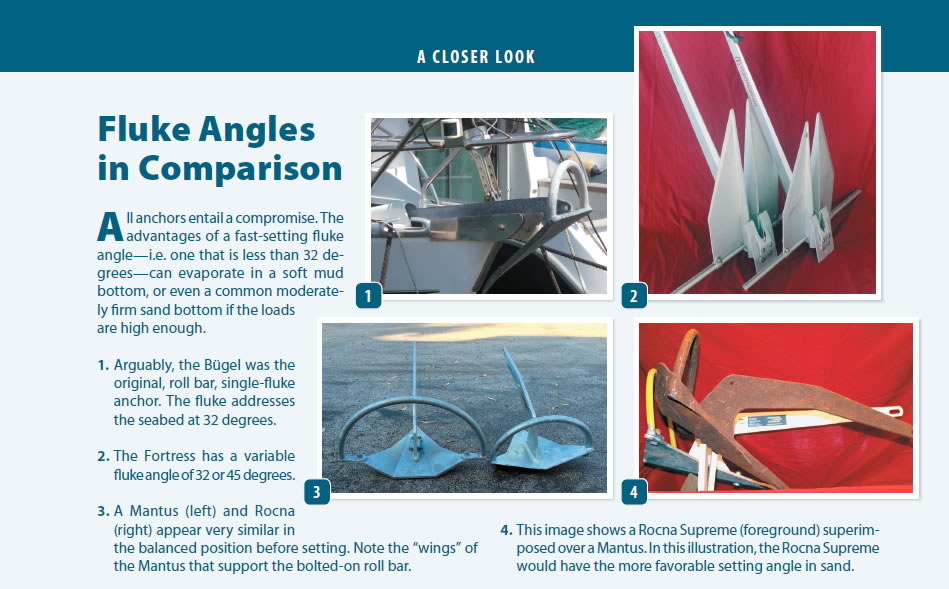

All anchors entail a compromise. The advantages of a fast-setting fluke anglei.e. one that is less than 32 degreescan evaporate in a soft mud bottom, or even a common moderately firm sand bottom if the loads are high enough.

- Arguably, the Bgel was the original, roll bar, single-fluke anchor. The fluke addresses the seabed at 32 degrees.

The Fortress has a variable fluke angle of 32 or 45 degrees. - A Mantus (left) and Rocna (right) appear very similar in the balanced position before setting. Note the “wings” of the Mantus that support the bolted-on roll bar.

- This image shows a Rocna Supreme (foreground) superimposed over a Mantus. In this illustration, the Rocna Supreme would have the more favorable setting angle in sand.