Teak offers many advantages that make it a great decking choice. Compared to other woods, metal, and fiberglass, teak is a good non-slip surface and is very durable thanks to its resistance to rust, rot, mildew, and UV damage. Its also fairly low maintenance; if left to turn silver, a regular rinse with clean seawater is all it needs as the salt and minerals help hold in moisture.

However, it has become increasingly difficult to find good-quality teak planking and the price of a new teak deck has skyrocketed-not to mention the industrys environmental impact. Even with teak-decking companies that preassemble the wood decking layouts and panels in the factory for a quicker installation, the price of a natural teak deck can still be twice that of synthetic teak deck. The number of new boats favoring synthetic teak over natural-both on deck and down below-is on the rise. In addition to being less expensive, synthetic teak is more lightweight, cooler, easier to maintain, and is available in many colors.

If you have an older boat with a teak deck that needs rescuing and you love the look of teak, you may want to consider installing synthetic teak rather than replacing the natural teak, painting a nonskid system, or applying nonskid mats like Treadmaster (see PS November 2013 online).

What We Tested

Practical Sailor tested five different brands of synthetic teak products marketed for marine use and sold in the United States. (Many similar products are also available abroad.) This is a very large field, so we narrowed our search to established players. Of those that we did not test, several seemed to be nearly identical to products we tested or they did not have a large share of the U.S. marine market.

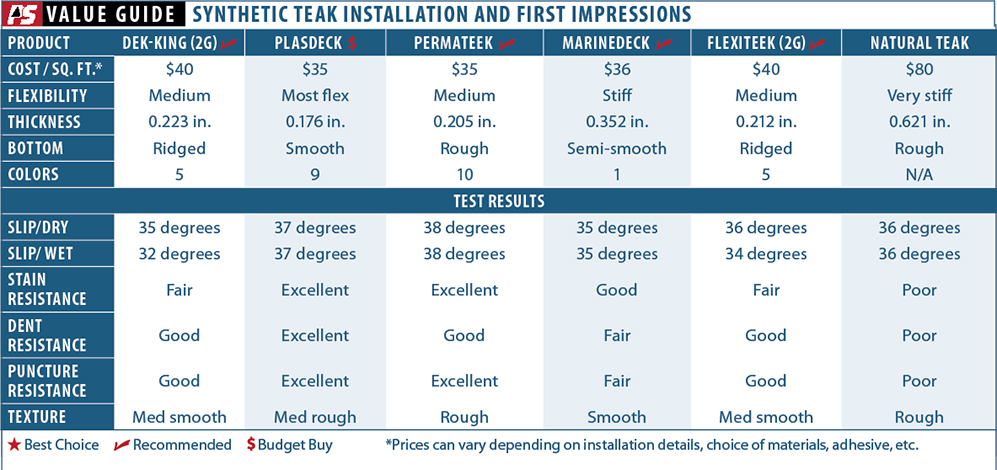

This report is the first in a multi-installment review of synthetic marine decks. It focuses on initial observations, stain and impact resistance, installation, and ease of maintenance. Test results are shown in the accompanying Value Guide table. A future report will look more closely at long-term durability. See How We Tested for details on the testing protocol and ongoing long-term testing.

Dek-King

Manufactured by Wilks Rubber/Plastics in Tollesbury, U.K., Dek-King is a PVC-plastic, synthetic-teak decking material. Ameriteak Marine handles most of the North American distribution, except on the U.S. East Coast, which is served by World Panel Products in Florida. Dek-King is available in five color combinations with black, gray, or cream caulking. Four are natural teak color, and one mimics a gray, weathered deck.

Dek-King sent us two 23-inch by 15-inch sample panels, along with a trowel, a couple of Sabatack 750 XL adhesive sausages, and simple installation instructions. We received samples of both the standard teak material and the new 2G material, which is 32-percent lighter in weight than the standard material and is slightly lighter in color. The company claims it is 30-percent cooler. It costs about 25-percent more than the standard product. The 2G is more popular with sailboat owners because of the lighter weight and cooler feel. Testers did notice the 2G was significantly cooler.

The ultraviolet-resistant composite product has a nominal thickness of 5 millimeters, tongue-and-groove edges for better joints, and inverted T grooves on the bottom for better adhesive bonding. The simulated caulk seams can be black or white.

If you provide Dek-King with a template of your deck layout, the panels can be pre-assembled as mats, simplifying the job for do-it-yourself customers. The material is also available in 32-foot rolls of various widths for commercial contractors and boatbuilders, which comprise over 80-percent of the companys sales. Wilks also makes composite faux-teak toerails, handrails, fendering products, and pre-assembled, fully welded mats.

Bottom line: Dek-Kings 2G material will appeal to those who are most concerned about reducing weight. It earns a Recommended rating.

PlasDeck

Made in Akron, Ohio, the PlasDeck products are the only U.S.-made material in our test; the company also makes a line of plastic lumber products.

Standard material comes in 32-foot rolls, either 2 inches or 6 inches wide with black, white, or custom caulking (blue, gray, cream, or a glow-in-the-dark material), and with straight or bullnose (radiused) edges. They offer 23 color and caulking combinations, for both exterior and interior decking, and will design and install any custom inlays, images, logos, or lettering you desire.

The samples we received included three 24-inch by 16-inch panels in tan, gray, and light wood coloring. Testers found the PlasDeck material to be the thinnest and most flexible of our test samples.

PlasDeck will sell its decking direct to do-it-yourselfers for about $20 per square foot, or they will provide pre-assembled sheets made from your boats deck template for about $35 per square foot; they also offer the option of having a local distributor measure, weld, and install the panels for about $65 per square foot.

Bottom line: Its affordable pricing makes PlasDeck our Budget Buy. This is also a sensible choice for U.S. clients or organizations seeking a custom logo, color, or design in their deck.

Permateek

Manufactured in the United Kingdom, Permateek has 13 distributors throughout the U.S. and Canada. The company does not offer the product in strip form for do-it-yourself installers, but it will make custom panels from templates provided by customers. For installers, that means there is no on-site cutting or waste. The kit comes complete with thermo-welded strips shaped to fit, adhesive, and instructions on gluing. All distributors offer on-site measuring, fitting, and installation service.

Permateek offers 10 color options-including traditional, weathered, and walnut-with black, silver, or white caulking. Pre-fitted panels range in price from $35 to $55 per square foot, depending on the complexity of the deck layout. Simple hatch covers or square swim platforms could be as little as $25 per square foot. The company recommends using Saba Sealtack 750 XL adhesive with the decking; each tube will glue about 15 square feet.

Bottom line: Top results in nearly all tests, Permateek earns a Recommended rating.

Marinedeck 2000

Made by Stazo Marine Equipment in the Netherlands, Marinedeck 2000 is handled by several distributors in the U.S. The Florida-based firm MarQuipt covers the U.S. and Caribbean.

A company with a unique departure from the PVC material of its competitors, Marinedeck uses natural cork with a hybrid synthetic binder compressed under pressure. This results in a thicker, stiffer, and seemingly more durable panel that feels softer, stays cooler in the sun, exhibits good nonskid properties, insulates, and deadens sound. The material feels much softer under foot than the others in our test.

Marinedeck comes in a variety of sizes in quarter-inch or one-third-inch thicknesses, in sheets, or different width planks, with and without seams or caulking. The cost of planks and sheets, and seam-binder (minus the adhesive caulk) runs about $36 per square foot.

Bottom line: Nonskid properties, feel, and durability make this a good product for those who don’t care about having a teak lookalike on deck. We Recommend it.

Product photo courtesy of PlasDeck

Flexiteek

Flexiteek is headquartered in Sweden and sold in the U.S. by the Florida-based Flexiteek Americas. Like Dek-King, Flexiteek has a 2G, second-generation, material that is 30-percent cooler and 35-percent lighter weight than its standard product. It comes in five colors, plus black for interior cabin soles, with black, gray, or white caulking; its sold in planks of various widths from 1 to 4 inches wide. The PVC-composite material uses a heat-welding process to bond strips instead of glued caulking for long-lasting seams, according to the maker.

The Flexiteek surface feels medium smooth, with a look and feel very much like sanded natural teak. In tests, its nonskid and heat retention were Good, similar to that of the Dek-King material. The company also offers matching composite material for toerails, rubrails, and various trim, edging, and angle sections.

Bottom line: One of the most widely available products in North America, and a longtime player in the field, Flexiteek earns our Recommendation.

Conclusions

Without any durability results (the subject of our upcoming Part II), we refrained from recognizing a Best Choice among the PVC-based materials. Permateek stood out for several reasons: It resisted staining the best and was a top finisher in our impact-resistance testing; it was among the grippiest surfaces. The only drawback is that distribution is more limited than others.

PlasDeck, an affordable option made in the U.S., was our Budget Buy for the do-it-yourselfer on a tight budget. Marinedeck earns a Recommended rating for its cork-based material that resists stains, does not get too hot, and feels smooth to the touch. Finally, Dek-King and Flexiteeks lighter 2G materials will appeal to racers or sailors in areas with an experienced distributor/installer. Both are recommended.

Your choice of a natural-teak decking substitute will depend on your preference of appearance and color combinations, your opinion on texture, and access to local distributor or installer.

For those facing a teak-deck replacement, you can install synthetic for about half what natural wood would cost. The synthetic is lighter, cooler, more flexible, and more stain resistant than teak, and there are more color and design options. But unless you are set on a teak aesthetic, a more practical long-term option is painting on a two-part linear polyurethane nonskid (see PS January 2012 and November 2013). While synthetic teak might nicely accent a cockpit, an LPU deck will be more abrasion resistant and less costly and time-consuming when it comes time

for renewal. No deck lasts forever.