Next to hull integrity, bilge pumps are a vessels first-and often only-line of defense against sinking. Not only do they serve to clear incidental water from the bilges (minor leaks, rainwater, etc.), but they can also give the crew extra time when taking on water-time that can be spent repairing the leak, donning life jackets, or making a distress call.

Bilge pumps shouldnt be confused with emergency pumps, which provide much greater output. However, having one or more regular bilge pumps installed can prove immensely valuable in an emergency, so long as those pumps are reliable, efficient, properly installed (see page 2), and well maintained.

The bilge pump market is crowded with everything from inexpensive hand pumps to high-capacity electric pumps. In the Feb. 15, 2004 issue, Practical Sailor reported on our comprehensive test of electric bilge pumps, which covered a range of flow rates from seven manufacturers. In 2000, we looked at dozens of pumps: manual units in the April 15 issue and electric pumps in the June 1 issue. This year, we opted to divide the test field into two groups based on output capacity to enable more of an apples-to-apples comparison and to make the data easier to digest.

What We Tested

Four manufacturers-Attwood Marine Products, Rule/ITT Corp., Shurflo, and Johnson Pump-answered our call for the electric bilge pump test, submitting a total of 18 centrifugal pumps for evaluating. In this issue, we report on the eight higher-capacity electric bilge pumps (output rated at or above 1,600 gallons per hour, or GPH) and see how they fared in exhaustive bench testing. A follow-up report in the October issue will examine pumps rated for 1,500 GPH or less.

Editors Note: Keep in mind that advertised output is usually the flow rate at the outlet, and doesn’t reflect real-world capacities. Recently, the American Boat and Yacht Council began stipulating that manufacturers also rate pumps under two more realistic conditions: with a head height of 1 meter and a hose length of 3 meters, and with a head height of 2 meters and hose length of 6 meters. Head height is the vertical height of the hose outlet above the pump outlet. When comparing output specs on two different pumps, make sure the rating criteria are the same.

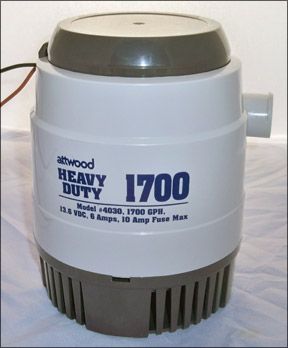

Attwood Marine is a leading maker of innovative deck hardware and a supplier of navigation lighting, fuel accessories, and other marine accessories. The Michigan-based company provided two pumps for the 1,600 GPH test field: Model 4030 (1,700 GPH) and Model 4060 (2,000 GPH).

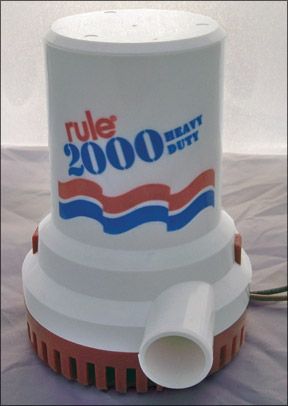

Rule is one of ITT Corp.s Flow Control companies, which also include Jabsco and Flojet. The company, which is headquartered in White Plains, N.Y., provided two pumps for testing: a 2,000-GPH Model 10 and a Rule-Mate 2000, the only automatic pump in this category.

Founded in 1968, Shurflo is a leading supplier to the marine and RV markets. Part of the Flow Technologies Group of Pentair Inc., the companys main facility is in Cypress, Calif. We tested Shurflos 2,000-GPH bilge pump, Model 358-010-00.

Johnson Pumps, which fielded three bilge pumps in this group (1,600; 2,200; and 4,000 GPH), has been one of the worlds leading marine pump makers for over 30 years. In 2006, the company became part of SPX Flow Technology.

How We Tested

Following the procedures of the 2004 bilge pump test, testers measured flow rates and power ratings on all pumps at two voltages while pumping fresh water into a tank set 4 feet above the pump. We also conducted a test to confirm compliance with the American Boat and Yacht Councils (ABYC) standards that state a bilge pump should be able to dry run at design voltage (13.6 volts for a 12-volt pump) for at least seven hours without failure. In the final analysis, we picked the top-rated pump based on performance, warranty, wiring and price.

Testers began with the dry run. To avoid any possible issues with our 50-amp CSI Speco PSR-50 power supply running all eight pumps at the same time, we operated them in two shifts. All pumps passed the dry-run test.

We mounted each pump to a test bench, added crimp-on ring connectors to the factory leads, and then connected them to a fuse panel with a fuse sized as close to specifications as we could find. Two feet of No. 14 wire connected our power supply to fuse blocks energizing the pumps. We monitored the supply voltage with a Fluke 77/BN multimeter and the pumps temperatures with a Craftsman Model 82327 non-contact infrared thermometer.

Testers warmed up the pumps with one hour of running time at 12.5 volts. We then increased the voltage to 13.6 (standard for a 12-volt pump) for the following seven hours. Total continuous dry running time on each pump was eight hours.

Flow testing was conducted at 12.2 volts and 13.6 volts. Testers used the Fluke multimeter to monitor supply voltage and a Craftsman 82062 DC/AC clamp-on ammeter to record power usage; voltages and current draw were both measured at the power supply. Testers timed how long it took each pump to fill a container of known volume, then used this to calculate each pumps flow rate. Each pump was tested twice at each voltage, and outputs listed in the Value Guide on page 25 are the average.

The pumps were tested using standard bilge pump hose sized to fit the pump discharge, which in all but one case was 1 1/8-inch diameter hose. The two larger Johnson pumps can be fitted with adapters to accept larger diameter hoses. The Johnson 2200 also comes with a 1-inch diameter hose adaptor, while the Johnson 4000 comes standard with adaptors for 1-inch and 2-inch diameter hose. Both were tested with the smaller of the compatible hose sizes.

As noted in the Value Guide, some of the test pumps can be rotated so that the outlet positioning can be adjusted after the pump is mounted. If the table lists a pumps outlet mounting options as having two positions, that means the pump has the typical two-prong mount and can be rotated 180 degrees. Those with four options can be rotated in 90-degree intervals, and those listed as being 360-degrees can be swiveled so that the outlet can be set in any position.

Setup Details

The test setup incorporated two plastic tanks, a 45-gallon supply tank and an 18-gallon receiver tank. Prior to each pump run, approximately 30 gallons of water was put into the supply tank. Each test pump was temporarily mounted onto a half-inch-thick piece of wood, placed at the bottom of the supply tank, and held in position with lead weights. Centrifugal pumps are not self-priming, so they must always be installed below the level of water they will be pumping, at all angles of heel.

For discharge hose, we used appropriately sized Shields VAC XHD Series 148 hose connected to each pump with a single clamp. It is smooth bore tubing and is recommended for use as bilge pump discharge hose. The test hoses were 6 feet long. The other end of the hose was attached using a single clamp to a plastic hull fitting mounted in the receiver tank, which was marked in two-gallon increments and located 4 feet above the level of the pump. This allowed us to have a set amount of head pressure so that our output findings were comparative.

Head (also referred to as static head) is the resistance that a pump has to overcome when pumping water up and out of the boat. It includes the resistance generated by the vertical distance the pump has to move the water up and any resistance generated by the discharge hose (kinks, ribbed interior). (For information on figuring head and vertical resistance, stay tuned for part 2 of this test in the October issue, or check out Nigel Calders “Boatowners Mechanical and Electrical Manual.”)

Electricity was supplied to each pump from the power supply through 15 feet of No. 14 wire to the fuse panel and then on to the pumps.

The wiring for all pumps was 16-gauge, tinned copper wire, with the exception of the Johnson 4000 unit, which used thicker 14 gauge. One aspect of the wiring that is of most concern to an installer is the length of the leads, which in our opinion, can’t be too long. If the leads are too short to reach the bus bar you’ll be forced to add more wire with a butt connection or junction box, either of which provides an opportunity for corrosion. That being said, the longer the leads provided, the further away you can keep the connectors from bilge water and the corrosive environment of the bilge in general.

RULE

We tested the Rule Model 10 and the Rule-Mate 2000, the only automatic pump in this test field. Both pumps were well made and are a common sight on recreational boats the world over.

Tested with 1 1/8-inch hose at the outlet, the 2,000-GPH Model 10 was a moderate performer, but the fact it reached 177 degrees during the dry run concerned testers. The fear here is the potential for overheating (and possible fire risk) should the pump be left on by accident or if a float switch gets stuck and the pump is allowed to run dry.

The Model 10 also had the shortest leads of any pump tested.

Automatic pumps are preferred for many installations; however, the feature does add to the cost of the pump. At $173, the Rule-Mate 2000 was the most expensive pump tested, yet it wasnt one of the top performers.

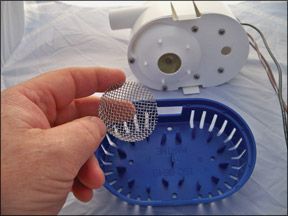

The Rule-Mate also features a mounting base strainer and a removable mesh strainer that help keep debris from clogging the pump. (See photo, page 28) This additional protection is a plus, but once the unit is removed from the base, the loose screen could be easily lost.

Bottom line: Both pumps, although they are quality products, were outperformed by other units in our test.

SHURFLO

Shurflo had a single entry in the 1,600 GPH and above group: the model 358-010-00 unit. Testers liked the quality of construction and “heft” of the 2,000-GPH Shurflo, which was one of the heaviest pumps of its size. We also liked the unique 360-degree swivel mounting option, as well as the 60-inch leads.

The best testimonial to the Shurflo, however, was its pumping capacity. The Shurflo filled our test tank faster than any other pump in the group (at both test voltages). While it drew a considerable amount of power compared to the other pumps, it also delivered in terms of water moved. It came closest to matching its advertised output (2,000 GPH, using its rated hose size) and pump model labeling with 3 feet of head.

Bottom line: Based on output, pricing and construction, the Shurflo 2000 is the top pick for this test group.

ATTWOOD

Attwood was represented with two test pumps, the 4030 and model 4060. Both pumps are well made and performed well during our tests. And both feature a clever twist/lock mounting that provides four different positions for the output once the base is installed. That being said, we were somewhat puzzled and concerned about the warranty: Attwood guarantees the pump for three years on recreational boats but only for one year in commercial applications. We understand that the policy addresses the increased demands of a pump in commercial use, but none of the other manufacturers make any qualification regarding warranty and how the pump is used.

Testers were not impressed with the Attwoods short leads, which measured 32 inches, the second shortest in the test group.

Bottom line:The 1,700-GPH Attwood Model 4030s output was close to its advertised output, and it is reasonably priced. Although we’d seriously consider spending a few more bucks to upgrade to the Shurflo 2000, the Attwood 4030 performed well for its size. Its the Budget Buy in this group.

JOHNSON

Johnson Pumps fielded three pumps in this group: models with GPH rated at 1,600, 2,200, and 4,000. All three were well constructed and reasonably priced; the 1600 and 2200 models were the least expensive of all those tested.

All three pumps ran the coolest during the dry-run. The Johnson 4000 ran 12-percent cooler than the Shurflo 2000, but pumped about 4-percent less water. Although the 1600 model used less power than any other pump tested, performance of all three Johnson pumps was among the lowest of the test group. Even the 4000 units output-which had our testers giddy with the anticipation of blasting the test supply tank dry-was less than expected. We tested the 2,200 with 1 1/8-inch hose but used the smallest hose that is compatible with 4000, which is 1-inch hose.

Bottom line: Although very reasonably priced, the Johnson pumps showed lackluster performance as compared to their advertised output.

Conclusion

When selecting the best overall pump from such a diverse group, several factors have to be considered to make the choice meaningful as it relates to the real world. In other words, just because a pump can move X amount of water with no head pressure or hose attached, thats no indication that it will be the best performer when its actually installed. Performance output specs that include head and lower battery voltages-like those used in our testing-help consumers make a more informed decision. The top performer in our real-world bilge simulation was the Shurflo Model 358-010-00, the Best Choice. The Attwood 1700 performed well for the money and is our Budget Buy.

For guidance on bilge pump installations and the results of our test of bilge pumps rated at 1500 GPH or less, stay tuned for next months review of lower-capacity electric pumps.

this is all god information, however, I am looking to find PS opinion on the better bilge pump CONTROLLERS. ie, the electronic device or just plain switch & pilot lamps that turn on & MONITOR the electric bilge pumps i have in place, . Id like to know what CONTROLLER is better in PS testers opine, eh?

Yes, a log of frequency and duration of pump operation would be very helpful to owners of old leaky boats.

I have used all the mentioned pumps on old leaky wooden boats and although not the fastest, Johnson have outlasted the consistant cycling by years. Generally budget 5-7 years on a johnson.

Rule has gone the way of Craftsman and for practical purposes, is a last choice. Even worse, the expensive 110v ac automatic pump has a three year warrenty and the brushes last maybe 18 months. It is advertised as a sump pump and all purpose tank pump, but just crap.

Ok, tests are good and a lot of feedback on these units.

One thing that is missing are the dimensions to fit into a bilge, considering many sailboats have tight bilges size wise.

Thanks for an interesting and very useful article but can you please clarify one point regarding the Johnson 4000 pump? The article states that “The Johnson 2200 also comes with a 1-inch diameter hose adaptor, while the Johnson 4000 comes standard with adaptors for 1-inch and 2-inch diameter hose. Both were tested with the smaller of the compatible hose sizes.” but the chart states that the Johnson 4000 was tested with 1-1/2″ hose. Can you confirm that 1-1/2″ hose was used for the test and not 1″ hose as implied by the wording in the text?

Very useful information, particularly as I’ve just recently replaced my bilge pump with a high capacity pump which is not included in these tests.

Hopefully, the manufacturers will pay attention to the issue of lead lengths. In every pump I’ve installed for 20 years now, that’s been an issue. I’d happily pay a few bucks extra for another five feet of wire on the pump so that connections could be made outside of the bilge. I have to buy that wire anyway.

Hi Guys,

Did you really test the Johnson Pumps with a smaller ID hose size than the other pumps, 1” vs 1-1/8”?

Pumps with a larger diameter hose will perform better by every measure.

This is not actually a comparison test, is it?

Really?

The Shurflo data sheet says “Run Dry: No”. You did test it running dry?