According to Earl Hinz, a veteran cruiser and a recognized expert on contending with heavy weather at sea, the concept of sea anchors can be traced back as far as 1200 AD when Polynesian mariners used stone ground anchors and lines fashioned from coconut fibers for the purpose of keeping their double-hulled canoes into the wind while at sea. (We extracted that nugget from Heavy Weather Tactics Using Sea Anchors and Drogues, Paradise Cay Publications 2000, one of several books Hinz has written.)

Hinz identifies the advent of parachute-style sea anchors as some time around World War II. It’s commonly understood that these devices began to gain favor among offshore sailors in the late ’70s and early ’80s. Since then, they have been refined and are now commercially available from several sources.

When properly deployed, a well-designed and well-built sea anchor can be an excellent tool to control vessel drift under a variety of conditions. If things go badly, and your vessel is adrift without power or a rig, a sea anchor can hold the vessel’s bow into a seaway, substantially improving the boat’s ability to safely ride out the weather. And if the need arose, a sea anchor could even keep a vessel in distress off a lee shore. For these reasons, many knowledgeable blue-water cruisers consider sea anchors manadatory safety gear.

Before continuing, it’s important to note that sea anchors are distinct from drogues. Hinz defines the former as “a large drag device deployed over the bow of a boat to hold the bow into the wind and the waves…A proper sea anchor will hold the backward drift to under 1 or 2 knots maximum…A sea anchor is used when the boat is disabled or the crew no longer wishes to sail, but would simply like to hold a relatively safe position and attitude with respect to the seas.”

A drogue, wrote Hinz: “is a smaller drag-producing device that is deployed over the stern of a boat to slow its forward progress when running downwind and, to some extent, to hold the stern to the seas…” It would be folly for any mariner to confuse the two or their respective applications.

We recently reviewed a group of six sea anchors, deploying three of them in actual tests conducted in 5- to 8-foot waves.

What We Tested

Fiorentino and Para-Tech, manufacturers well known for their high-quality, parachute-style sea anchors, provided a number of samples for testing and review. (Both companies manufacture sea anchors in various sizes up to 40 feet.) California-based Fiorentino has two lines of sea anchors and sent samples of each. The Coast-9 is a 9-foot diameter anchor designed, as the name implies, for coastal operations. The FPA-9, also 9 feet in diameter, is a heavier duty sea anchor designated as the offshore model. Fiorentino also sent a Coast-16 and FPA-18.

Colorado-based Para-Tech sent one anchor—its 15-footer. Our test boat—a 25-foot center console powerboat weighing 3,100 lbs.—was already equipped with a 9-foot model from Para-Tech.

How We Tested

The 9-foot sea anchor kept aboard our test boat is set up with a 20-foot rode of half-inch, three-strand nylon, a primary float, and 50 feet of half-inch polypropylene trip line. (It’s actually a drift-fishing setup for use when the waves don’t exceed five feet.) We used this setup as the first stage of our test for the 9-foot sea anchors.

We also tested each by adding 300 feet of 1/2″, three-strand nylon line to the sea anchor to mimic the rode length that one might use during heavy weather conditions in an emergency. Fiorentino provided floats and a trip line for its 9-foot sea anchors, and we deployed both with that provided gear. This same rode was used for all the sea anchors we deployed. As each test was completed, we switched the rode over to the next anchor using a large shackle to secure it to the parachute thimble.

Strong east winds blowing for several days prior to our test produced wave heights of 5 to 8 feet during our deployment testing. In addition to the consideration given for in-water testing, the 9-foot sea anchors were also reviewed for price, construction quality, and warranty.

The larger sea anchors were not suitable for in-water deployment with our test boat; but we did review their specifications, construction quality, pricing, and warranties.

Fiorentino

Fiorentino uses similar construction techniques on both its 9-foot sea anchors. The offshore-designated FPA-9 and the lighter-duty Coast-9 use a multi-section canopy fashioned from 8 oz. nylon, with 2″ nylon webbing sewn onto the skirt and 1″ nylon webbing on the vent hole opening. Shroud lines are multi-braid nylon line rated at 2,500 lbs. breaking strength. To make a solid connection to the canopy, each shroud line is sewn directly to the canopy over a total length of 14″.

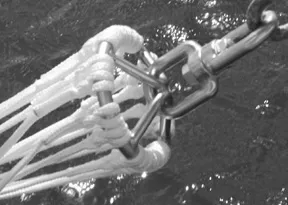

The bitter end of each shroud line is double-looped over the Para-Ring® (see photo above) and locked in place by back-sewing two inches of the line together. The Para-Ring® is approximately 6″ in diameter with two U-shaped brackets welded to the ring, which secure a large swivel. All Para-Ring® components are stainless steel. The swivel serves as the attachment point for the sea anchor rode. Additional multi-braid nylon lines attached around the vent hole of the canopy serve as the tripline attachment point.

Both Fiorentino’s 9-footers have 2 pounds of lead weights sewn into the canopy skirt on one side to stabilize the chute in the water and to encourage it to sink beneath the surface. A stowage bag is included with the purchase of any Fiorentino Coast or Offshore sea anchor, along with an instructional DVD or video.

Here are the differences between the two 9-footers: The more heavily built FPA-9 uses 16 sections in the canopy construction, whereas the Coast-9 uses only eight. It also has twice the number of shroud lines; again 16 for the FPA-9 and eight for the Coast-9. The Para-Ring® and swivel are also a size larger on the offshore sea anchor and the nylon panels have a higher thread count. At the tripline attachment point, the inshore model uses four lines while the offshore one uses eight. And the FPA-9 weighs 19 lbs., whereas the Coast-9 weighs just 13 lbs.

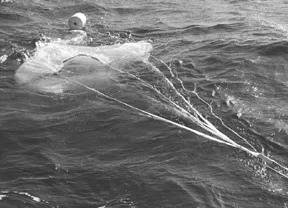

Both Fiorentino 9-footers performed well in the moderate sea conditions present during our testing. When we tested each with the short fishing rode, there was significant reversing in rode pressure from taut to slack as waves and troughs alternately rolled under the boat. This is to be expected when using such a short lead under these sea conditions. Once the rode was lengthened to 300 feet, the boat settled smoothly into the waves, maintaining a course within 20 degrees of directly into the seas. Whenever a series of larger waves rolled through, the boat centered up and headed dead into the waves.

We deployed one of the 9-footers using an optional Fiorentino deployment bag. The other went straight in the water without a bag. Both deployed properly without any tangling, which is a critical issue when deploying sea anchors.

The two larger Fiorentino sea anchors we examined, the Coast-16 and the FPA-18, are constructed in a like fashion, using the same materials as the smaller chutes. Each is beefed up to provide the needed additional strength to support the strain that largers vessels would put on these devices.

The Coast-16 canopy is constructed in 12 sections using the same number of shroud lines run to a Para-Ring® the same size as the one on the offshore FPA-9. The slightly larger and more heavily built FPA-18 has a canopy with 28 sections and the same number of shroud lines fitted to a heavy-duty Para-Ring®.

At Fiorentino’s website we found the Coast-9 priced at $396 and the offshore FPA-9 for $677. The price includes free freight within the U.S. The warranty on all Fiorentino sea anchors is five years. Optional rigging gear available from Fiorentino includes floats, trip lines, and of course, an anchor rode.

Bottom Line: These are top-of-the-line sea anchors, well built, using high-grade, 8 oz. nylon panels and stainless-steel hardware.

Para-Tech

The 9-foot Para-Tech sea anchor uses eight sections of 4 oz. nylon to form the canopy. The seams in the canopy, the canopy skirt, and vent opening are all reinforced with nylon webbing. On the seams, 1/2″ webbing is used with 1″ webbing strengthening the other areas. Heavy-duty 1/2″ webbing is used for the vent hole shroud lines while a heavier webbing strap serves as the float line attachment point.

The main shroud lines, made from 9/16″ tubular nylon webbing, are sewn onto the bottom five inches of the canopy at section seams. Additional webbing serves to connect the reinforced skirt to each of the eight shroud lines. Shroud lines terminate into a pair of 22″-long straps made from 1″-wide, heavy-duty nylon webbing shaped to hold the anchor rode attachment shackle.

Para-Tech products are “failure tolerant,” meaning if the whole system is over-stressed, the sea anchor is designed to blow a panel, but will still keep a boat’s bow into the seas though the rate of drift will increase slightly.

A 10-foot section of float line, made of the same material as the main shroud lines, is attached to both the chute and a storage bag that comes standard with the Para-Tech sea anchor. When stored, the 9-footer fits in a bag that measures about 8 inches in diameter and 10 inches high.

We rigged our sea anchor with 50 feet of additional tripline by attaching it directly to the short section of factory installed tripline. The anchor rode for fishing is only 20 feet long; it attaches to the parachute shackle on one end while the other end gets looped over the bow cleat. We used a long line float and clip to attach the float for deployment.

The trip line is secured to the bow cleat; that way we can quickly and easily collapse the sea anchor by hand without powering forward with the boat. This setup makes pulling the anchor quickly quite easy.

Unlike the Fiorentino sea anchors, the Para-Tech products carry no added weight in the canopy. Para-Tech sea anchors don’t rotate, say company representatives, because of the unique pattern of the canopy seams. We detected no rotation with Para-Tech’s 9-foot model while deployed.

The performance of the Para-Tech 9-footer was identical to the pair of Fiorentino sea anchors, both on the short fishing rode and on the long rode. The anchor was deployed directly from its storage bag (included with the Para-Tech); it did require a couple of tugs on the main rode to get the anchor out of the bag. Once out, it deployed cleanly with no tangling.

The Para-Tech 15 is a 9-footer on steroids. It uses the same canopy material, but is made in 16 sections and uses 16 main shroud lines. These terminate into four, 36″ x 2″ sections of nylon webbing that form a hole for a large shackle. When packed in its stowage bag, the 15-footer measures 11″ in diameter and 15″ high.

We priced the Para-Tech anchors on the company’s website. The 9-footer is $349 while the larger 15-footer is priced at $859. All Para-Tech sea anchors carry a five-year warranty and come with a stowage bag, float line, heavy duty shackle and instruction manual. Available accessories include anchor rodes and a choice of stainless, galvanized or titanium hardware.

Bottom Line: The Para-Tech 9-footer is a well made product. It differs from the Fiorentino in a few key ways, particularly that its panels are made of lighter nylon material and its shroud lines are made from nylon webbing instead of line, and rated for 2,000 lbs. breaking strength instead of 2,500 lbs.

A Word to the Wise

In his aforementioned book, Earl Hinz spends almost 30 pages discussing the proper use of sea anchors. There’s an important reason for this. Improperly deployed sea anchors can lead to disastrous consequences.

Determining the size and length of the rode you use in conjunction with a sea anchor are important considerations. “It is essential,” wrote Hinz in his tome, “that the length of the sea anchor rode be matched to the wave length of the sea…” He recommends setting the length of the rode so that both the boat and the canopy ride on the crests of immediately adjacent waves. That way, “they experience the same orbital motions of the surface water and hence move in harmony with each other.”

The diameter and strength of the rode should be determined with a number of factors in mind. “The rode,” explained Hinz, “…must have elasticity to absorb surge loads. For this reason, nylon rope is the best choice.” He favors braided line over three-strand despite the loss of elasticity.

For the serious offshore sailor and novice alike, Hinz’s book can be an important resource for selecting a sea anchor and rode. (See PS Aug. 1, ’00 for advice on sizing a sea anchor.)

Conclusions

All of the sea anchors we looked at are of good quality and should last for years considering how rarely they’re used. There are also others on the market that we didn’t test, including those from Dan Shewmon, Cal-June, and W.A. Coppins in New Zealand.

The 9-footers that we tested in the water performed properly. They are well constructed and carry substantial warranties. If not for the difference in the weight of the cloth used to fabricate each companies’ product, and the rated breaking strength of the shrouds, we’d be left with little but price to pick a winner. But that’s not the case.

Yes, the 9-foot sea anchor from Para-Tech is less expensive than its counterparts from Fiorentino, particularly the FPA-9. However, Para-Tech doesn’t include a swivel, which would add $40 to $60 to the price, and shipping isn’t included either. But sea anchors are products intended for use in emergency situations, and at those times, we’d feel more comfortable relying on something that’s overbuilt. Because of that, we’d gladly pay the additional money for Fiorentino’s products because we feel their more rugged construction will enable them to endure Neptune’s savage moods longer than those from Para-Tech.

Also With This Article

“Spec Sheet: Sea Anchors”

Contacts

• Fiorentino, 800/777-0732, www.paraanchor.com

• Para-Tech, 800/594-0011, www.seaanchor.com