Without really meaning to, over the past several years, Practical Sailor has acquired a considerable reputation for testing anchors and anchoring gear. On more than a dozen occasions anchor makers have sent anchors to be included in these PS tests. Inventors, too, have sent prototypes. (The notion of a perfect anchor is so intriguing that inventors are, we’re positive, out there working right now.)

When PS first looked at this situation back in 1997, there had been dozens of tests run by manufacturers (and testing organizations in their pay), other magazines, independent authors of books on the subject, and even government-allied groups. Among these were the French APAVE, the U.S. Navy tests, the RNLI (Royal National Lifeboat Institution) in England, the Boat/US-Cruising World magazine strength tests, the Dutch tests (done in a huge sandbox), the on-going tests by naval architect and author, the late Robert A. Smith, and the extensive “Seattle Tests” co-sponsored by the Safety at Sea Committee of the Sailing Foundation and West Marine.

Close examination of the results of these tests, plus careful readings of books, like Earl Hinz’s Complete Book of Anchoring & Mooring, Don Bamford’s Anchoring, and the revered Chapman’s (probably the best-selling marine book of all-time), suggested to PS that the tests were too omnibus (in most cases, the bottom was not even known or varied). The tests tried to do it all.

a trip line and buoy to gain some room, but long term use of a conventional trip line would risk snagging and draw some ire.

In our due diligence, we also checked a new book, International Marine’s Small-Boat Seamanship Manual. It came out in 2002 and is “Based on the U.S. Coast Guard Seamanship Manual.” All the many photos were supplied by the Coast Guard. Only six pages are allotted to anchoring and the only table is a very small one supplied by Danforth, giving three anchor sizes for boats 10, 30 and 40 feet in length.

Another book we examined was Staying Put, by Brian Fagan, who enjoys a strong reputation on the California coast. The book has a minimal table showing boat size (20 to 50 feet); the recommended size of chain (both proof coil and high test) and nylon rode, and what size anchor, as long as it is a CQR, Delta, West Danforth type, or Bruce.

BETTER MOUSETRAPS?

One of sailing’s acknowledged authorities, John Rousmaniere, in his tome The Annapolis Book of Seamanship, uses tables from both the American Boat & Yacht Council and the Earl Hinz book mentioned above. The Hinz table deals only with Danforth-type, plow, Bruce, and yachtsman anchors, but does make chain and line rode recommendations. Rousmaniere also makes the puzzling statement, “Nylon rode should be half-inch in diameter for every nine feet of boat length overall.” Going by that prescription, a 40-foot boat needs a hawser more than two inches in diameter!

Another authority, Steve Dashew, in his huge (1,232 pages) Offshore Cruising Encyclopedia, tap-dances for a half dozen pages around the subject of anchor loads, but summarizes with: “You should carry the largest possible anchor and use it for everyday anchorages.” He also “suggests” as a main anchor “the largest Bruce you can carry, twice the size of what everyone else suggests…,” and a big Fortress as a second anchor. He likes a chain rode. We think it’s good, conservative advice.

DEALING WITH THE CONFLICTS

Because of all the conflicting and imprecise data, Practical Sailor concluded that anchor testing should be broken into small sections that can be assembled by a boat owner to suit his or her needs. It was determined that the predominant “sections” were:

1. Setting (if an anchor doesn’t set, it isn’t an anchor).

2. Holding (with dragging as a derivative).

3. Re-setting (or holding) when veered.

PS settled on four other factors to be considered, after the above three. They are: (1) the difficulty of breaking out; (2) weight on board; (3) quality of workmanship, as it pertains to long-term utility, and (4) ease of handling and stowage, either at the bow or in an anchor locker. For some owners, self-launching and automatic retrieval might be added to the list.

The next question is, of course, in what? Fine sand, coarse sand, that crusted sand found in tropical waters, good solid mud, gravel, the deep thin mud found in Massachusetts’ Nantucket Harbor (which was from 1800 until 1840 the whaling capital of the world), or the soupy ooze encountered in the tributaries of the Outer Banks of the Carolinas? That question led to the decision to conduct separate tests in clearly identified bottom conditions.

Next question: What kind of boat and what wind and water conditions? Along with bottom composition, these factors are vital.

After winnowing wearily through the possibilities for testing, PS settled—because we had to settle on something—on a 30- to 32-foot sailboat, in sheltered water, with no more than 40 knots of air (which is classified as the top end of a “fresh gale” or Beaufort 8).

Boat length and wind velocity are the two components in the tables usually seen in marine catalogs, manufacturer’s data, and general marine reference books. And a few include the boat’s beam.

The real questions for any boat owner are:

A. In what kind of conditions—wind, bottom and waves—do I expect to anchor?

B. For the conditions, how much of a load, or “pull,” will be exerted on the components (anchor, rode, shackles, etc.) in my anchoring gear?

Getting to that single figure isn’t easy. But without it, how can one select an anchor? Or a rode, or whether it should be nylon line or chain? And it’s even more difficult to reconcile this quandary with the customary tables that are intended to help you select an anchor.

West Marine’s 2004 catalog has an “Anchor Selection Guide” featuring tables that specify different styles of anchors (fluke, plow, Bruce, etc.) and specific models relative to boat length from 0 to 120 feet LOA. There’s also a full-page Advisor on anchor rodes.

(A pause here, if you please, in defense of such tables, which can’t possibly place on a single grid all the conditions that affect anchoring. The worst omission, however, is leaving out wind strength, a vital factor that could be stated in a single line.)

The 2003 Defender catalog has half a dozen tables supplied by manufacturers, such as Fortress, Guardian, Danforth, and Simpson Lawrence. The Fortress and Danforth charts show holding power in pounds, but only the Danforth data supplies wind strengths (20 knots and 60 knots).

The 2002 Boat/US catalog uses boat length and holding power in pounds for anchors made by Suncor, Danforth, CQR, Bruce, Fortress, Delta, and others. Stating the holding power is admirable, but for what wind strength?

“Holding power” (Item B above) is at the heart of anchor and rode selection. Put another way, it begs the question, just how hard does your boat pull on that anchor? And an integral part of the problem is (Item A above), “In what bottom and with what wind and waves?”

THE ABYC VS. ROBERT SMITH

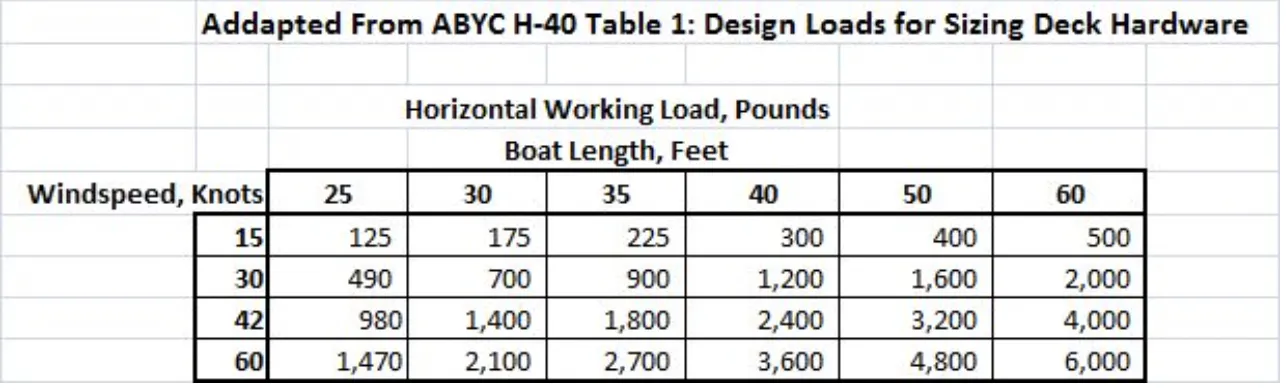

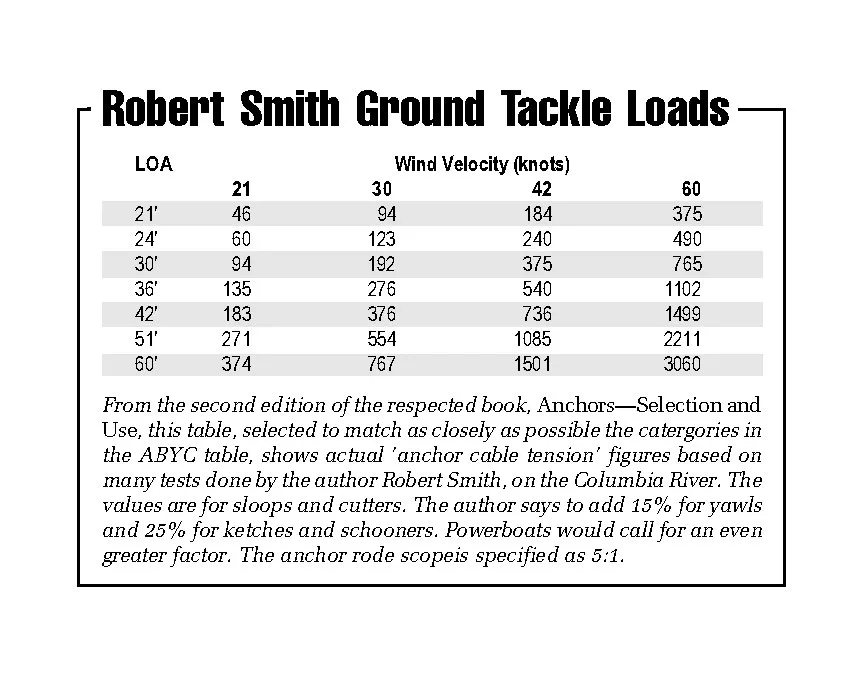

The American Boat and Yacht Council calls holding power “Typical Design Horizontal Loads in Pounds.” Robert Smith, a naval architect and engineer who spent many long days testing anchors, calls it “Calculated Rode Tension in Wind and Waves.”

The ABYC data comes in a table reproduced in abbreviated form above. Smith’s table included in a sidebar at the end of the article. A cursory examination will tell you that they are wildly dissimilar.

For wind strengths, the ABYC table gives a set of figures for “Lunch Hook,” “Working Anchor” and “Storm Anchor,” which corresponds to winds of 15, 30, and 42 knots. If you expect to anchor in 60 knots (typical in summer thunderstorms), you multiply the “working anchor” value by four.

Along the other side of the table are boat lengths from 20 to 60 feet, in five-foot increments, but modified by a second column giving a boat’s beam (for both power and sail). A footnote says that for your boat, use whatever combination gives the highest load.

The ABYC data is good, conservative stuff, which is where one should be positioned when buying an anchor and a rode that will stand up to the extremes. The selection should be made on a thoughtful pre-determination of the worst conditions in which one expects to anchor. The problem is, of course, that after building an anchor system based on 42 knots you find yourself stuck in a rather open anchorage during a two-day gale that wasn’t supposed to happen.

In sharp contrast to the ABYC data is the data published in the table of the third edition of Robert Smith’s 1983 book called Anchors—Selection and Use (see table at end of article).

Smith told PS (a year or so before he died in June of 1997) that he obtained his data from testing in a level area of the Columbia River that has a fine sand bottom and a fetch of four miles to windward. He used several boats, both power and sail. With a 30-foot boat anchored in 30 knots of wind, the ABYC says the load on your anchor system will be 1,200 pounds. Using Smith’s figures, the load will be only 341 pounds. The figures, if used to help you determine what size anchor and rode to use, will produce radically different choices.

One more example: if you have a 30-foot sailboat and get caught on a night when a 60-knot squall goes through the protected harbor in which you’re anchored, the ABYC says the pull on your anchor rode will be 2,800 pounds. Smith says it would be 765 pounds. The ABYC figures are about 3.5 times greater than Smith’s. When asked to explain these wild discrepancies, Smith said, “I don’t know how they got their figures; mine are real, developed by actual testing.”

As originally explained by Tom Hale, then the ABYC’s technical director, the ABYC data was developed in the 1950s to indicate the strength required of an anchor bitt or cleat. Hale said it is not unreasonable to apply the figures in the chart entitled “Ground Tackle Loads” to the entire anchor system (as has been done in various catalogs and books). Hale said the ABYC tests (done with a 40-foot boat by Bob Ogg, who developed the Danforth anchor) assumed a “worst case” situation, including sea state and surge. Hale also said the figures were subjected to a hefty, but now unknown, safety factor that over the years has made the table a trustworthy guide.

Philippe Ras, the ABYC technical director until 2003, said the much-used Table 1 in H-40 of the “Anchoring, Mooring, and Lifting Section” of the ABYC’s voluminous standards now is entitled “Design Loads for Sizing Deck Hardware.”

FEEL LIKE SOME TOUGH MATH?

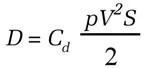

If you want information that’s less general, something more specific to your boat, you can calculate the load (or drag) on your ground tackle—that is if you’re very patient, meticulous, and mathematically inclined.

It’s all based on Isaac Newton’s wind-drag data, developed in the late 1600s, which became highly refined after the precision of aviation research subsequently improved.

As presented in Don Bamford’s book, Anchoring, the formula for drag (D) in pounds per square foot remains (see right):

Cd is the coefficient of drag, p is the density of air, V is the wind velocity in knots, S is the boat’s cross-sectional area (in square feet) taken at right angles to the wind.

You can, for p, substitute the U.S. standard atmospheric air density of .0023779.

For S, you’ll have to measure and do some geometry on your hull, mast, cabin, boom, dinghy, lifelines, stanchions, pulpit, and everything else (including any pretty girls you habitually carry up on the bow) that creates wind resistance. You then need to increase some of the figures for however much your boat yaws at an anchor.

For Cd values, Earl Hinz, in his book, The Complete Book of Anchoring and Mooring, supplied some general guidance with this table:

Angular tramp steamer – 1.2

Cabin cruiser – 1.0

Morgan OI-41 – .9

Oil tanker – .85

Cruising trimaran – .55

Racing trimaran – .45

Airplane – .09

Even better, Bamford says a sailboat with a “really sleek” superstructure will run as low as .70, but a blocky pilothouse or even a dinghy strapped on deck would push the figure to 1.00. He simply suggests using 1.00.

If you anchor in a current—say five knots, with a 40-foot boat, Hinz says to add 300 pounds to the load. Bamford says to add 10 percent.

For surge loading from wave action, Bamford says it isn’t important in normal anchoring, if you have a sure-fire way to prevent snubbing. Hinz says that in severe conditions, the up-and-down jerking can double the load, especially if the boat is heavy displacement.

Both Bamford and Hinz are emphatic in noting that the load increases as the square of the wind velocity. In other words, if the wind doubles from 30 to 60 knots, the load is four times greater.

Intimidating, isn’t it?

FURTHER BECLOUDING THE ISSUE

Neither the manufacturers’ data nor the Smith tables mention wave action; presumably, you’re supposed to anchor in very sheltered water, as we’d all prefer to do.

And in none of the data is there any mention of the bottom conditions, which is probably the greatest variable of all. Despite that getting the hook to “grip” is sometimes the most difficult facet of anchoring, the tables simply presume that you’ve induced the anchor to take a very firm hold on the bottom—be that sand, soft mud, hard clay, rock, shingle, coral, sawdust, or an old shipwreck—and that it will not drag in any wind shown on the table. (Perhaps the most surprising fact that emerged from PS’s many anchor tests is that an anchor never, ever stays put exactly; even a light load “works” an anchor in the direction of the pull.)

We firmly believe that anchors should be tested under different conditions to derive useful data. Good engineering practice holds that tests must support theoretical or calculated data (an anchor’s “holding power” often is calculated as “frontal area” by the manufacturer.) And with anchors, testing is not easy, not only because of the many variables, but also because it’s plain hard work.

As mentioned, there is no dearth of tests. Some are independent tests; more often they are sponsored by an anchor manufacturer or inventor. We’ve never seen a sponsored test that did not come out favoring the sponsor’s anchors; those that don’t must get unpublicized burials. Peculiarly, even the independent tests never have produced results that point a shining light on the perfect, all-purpose anchor, the one that sets every time and holds better than all others, in all bottoms. That has led most experienced sailors to conclude that you should carry two, or even three, different types of anchors.

Even the French-made Spade does not top all others in all of the PS tests.

THE BOTTOM LINE

So, what’s a body to do? What size anchor do you need? And what size nylon or chain rode should you use to hook it up? It depends, of course, on what kind of anchoring you expect to do. If you never venture out in anything even slightly resembling threatening weather, you can go with the recommendations of most manufacturers and those based on Robert Smith’s tables. Generally speaking, this data would appear to fall in the minimum category. Remember: You’re going with the minimum and there’ll be trouble if you get caught in any conditions other than that.

If you’re the type who prefers to be prepared for anything, you’ll need powerful gear based on the ABYC tables, which, compared with other advice, call for much heavier gear—both anchors and rodes.

Even when so equipped, there are places so notoriously bad for anchoring (such as off some of the California islands and the old, ooze-filled whaling harbor at Nantucket, south of Cape Cod) that savvy sailors don’t even attempt to anchor in these locales; they pick up moorings, go into docks, or leave.

In the final analysis, consistently successful anchoring calls—most of all—for good judgment based on knowledge and experience. And, here and there, a goodly helping of pure luck.

TESTING NEVER STOPS

The ABYC table indicates “design load.” Design load is defined as

“The total load on a structural system for the most severe combination of loads and forces which it is designed to sustain.”

(https://en.wiktionary.org/wiki/design_load)

“…prescribed minimum load requirements are actually based on the expected maximum load […] over its lifetime. As such, design load requirements will exceed the true live load that a structure will actually bear.”

https://www.nishkian.com/live-loads-explained-for-structural-design/

This I suspect is the major difference between the ABYC table and Mr. Smith’s empirical measurements. They’re both right; one way to think of it is the ABYC table includes a safety factor of 3.5x. But you want to size your system and equipment around the design load, not the live load.

Good history article. However, we have learned more since then. Let me add some of it here:

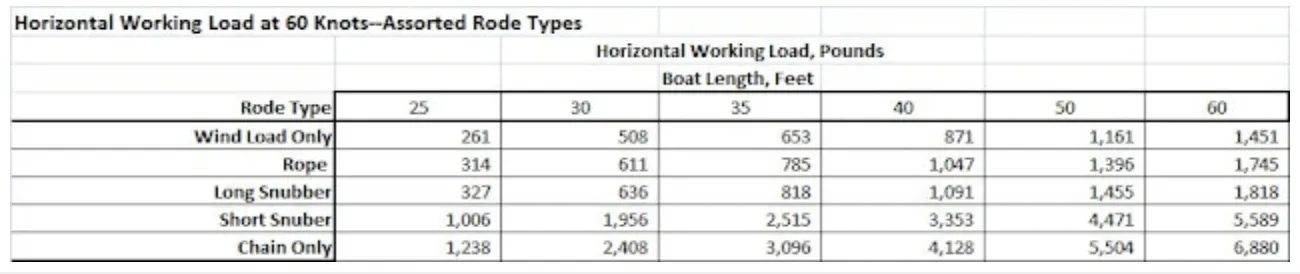

The reason the ABYC numbers are higher than common experience is because they are actual worst-case values, obtained when the boat is anchor in shallowish water, with all-chain rode and no snubber. In fact, PS documented this in “What is the Ideal Snubber Size,” March 2016, page 13. The average peak load is 3-4 times lower, but loads matching the the ABYC H-40 Table 1 figures are not only possible but probable if anchored in a worse-case location with all chain and no-snubber. In fact, further study of the ABYC H-40 standard reveals this, because the working load of a rope rode of the size recommended in table AP 1 is 3-4 times lower than Table 1, reflecting that loads are expected to be much lower with the impact absorption provided by the nylon rode. If you went by the fatigue strength in Table 1, you would be matching 7/8-inch rope with 1/4-inch G40 chain, which is ridiculous and would not pass the windlass. In fact, 1/2-inch rope is used with 1/4-inch chain, with a working load of 709 pounds vs. 2600 pounds for 1/4-inch G40 chain, or 3.7 times less. Nylon stretches, and thus the mystery is solved. The take away is to always use a snubber if anchored in shallow water (anything less than about 20 feet).

In fact, the peak load has less to do with wind force than the waves the wind generates. It is when a wave strikes, as the boat is yawing and the catenary comes out of the chain rode, that peak forces occur. This is VERY difficult to calculate, which is why several PS authors, primarily Drew Frye and Johnathan Neeves, spent weeks on the bows of several different boats ~ 2015-2018, measuring actual loads with a range of snubbers and yawing controls. Some of the testing was a little scary and at least one load cell exploded when a wave hit. It’s all in the archives.

Table 1 is not the result of conservative standard, or a large safety factor, it is the result of actual test results, duplicated by PS. There is, of course a safety factor of sorts built into working load calculations; the working load is about 3-10 times lower than the breaking strength of the material, but this is not a matter of caution, this is related to the fatigue limit of the specific material and construction. If the working load is exceed through enough cycles, the material fatigues and breaks at the working load.

There are also, obviously, a good few new anchors since then, Excel, Mantis, Rocna, and Viking, to name just a few. Weaknesses reveal themselves as they are tested and as sailors report in. For example, Rocna MKI has a documented tendency to collect sticky mud and then not reset. Will the Rocna MKII solve this? We don’t yet know. I guess we’ll have to get one and find out.

There are also newer books on anchoring, including “Rigging Modern Anchors,” 2018 by PS’s own Drew Frye.