Sailmakers around the world have been printing up new business cards even though they continue to work for the same franchised lofts. Their new cards have swapped job description titles from “sailmaker” to “sail designer,” a result thats partly due to the proven value of computer-aided design and partly due to a growing trend toward sending sailmaking overseas. Like so many other industries, sailmakers have responded to the lure of lower labor rates and the growth in high-tech manufacturing skills in Asia. Many of the big-name lofts have curtailed much of their domestic sail production and instead focus on building each customer a virtual sail in their local loft, digitizing carefully made measurements, and electronically forwarding the data to a mega loft on the other side of the globe.

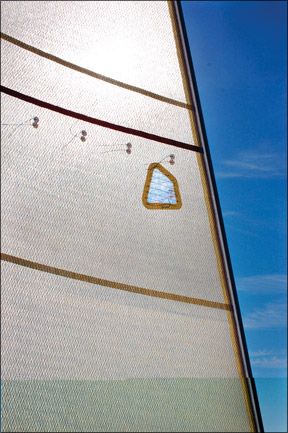

Photos by Ralph Naranjo

Sailmaking success continues to be measured in units of satisfied customers, and despite the remote location of the loft floor, this globalized approach seems to present a viable model, both from the perspective of the consumer and the business. Its true that not as much dialogue can take place between the loft salesman, sailmaker, and skipper-a kind of collaboration that in the past led to some important decision making and genuine brand allegiance. But a capable sail designer can still deliver the goods. To do so, he must address three critical points: capture accurate initial measurements, use sophisticated design software to customize sails for the specific boat, and match the design work with the sailing preference and crew skill level.

Fortunately for those who savor the working relationship that they have had in the past with their favorite salesman/sailmaker, there are still smaller independent lofts where sewing machines continue to whir away and where the sailmaker who built your sails is still willing to join you for a sea trial. Such lofts are like independent hardware stores-an endangered species, something well all certainly miss when the full effect of centralizing sailmaking takes hold. Some of the independents will survive on the repair work that the sailing season generates, but many see the handwriting on the wall and are turning production over to wholesalers such as China Sails Factory in Guang Dong Province, Southern China.

The recent industry trend toward moving production offshore is anything but a new idea. For decades, Neil Pryde has proven that theres merit in Adam Smiths business model of leveraging cost-effective manufacturing even if it separates the plant and the purchaser.

Prydes business plan has worked, and it has proven to be a globalization win-win for most, if not all, of the players involved. Now, with others jumping on the Asian mega-loft band wagon, one can only wonder what the long run will hold for domestic sailmakers.

Rich McGhee, president of U.S. sales for the China Sails Factory, and Skip Dieball, director of One Design, are strong advocates of the cost effectiveness of moving sailmaking offshore. One of their sailmaker clients summed it all up by saying, “We can’t even make sails for what the overseas lofts sell them for.”

Many namebrand lofts use China Sail Factory for some of their sails. Not only is the workmanship solid, but by specifying a particular sail material, the worry over substandard sailcloth can be avoided. One sailmaker we spoke with said that he always recommends picking a top of the line Dacron and opting for the blue water upgrade.

China Sail Factory is becoming the 800-pound gorilla of modern sailmaking, and it has turned into the sailmakers sailmaker-creating product for Hood, North, Doyle, Banks, Elvstrom and a couple of dozen other very familiar namebrand lofts. The deal is wholesale only, and local sailmakers all over the world use China Sails as their manufacturer for some or all of the product that they sell. In this way, individual lofts still interact with customers, making sure that the measurements and sail construction details are as specific as possible. In addition to digitally identifying the specific shape and sailcloth to be used, the local loft can input the location of reinforcing patches, hardware, batten pockets, and their company logo. Feedback from the pros indicates that China Sails delivers on time, and the finished sail is a high-quality product.

The success of this remote manufacturing process is much like the magazine business, a process in which editorial content and design come together at one location, but the printing process takes place elsewhere. The challenge to both industries is getting a completely accurate digital file depicting the sail or the publication to the computer at the production facility. In the case of China Sails, the production team underscores that they do not measure masts or sails with customers; thats the job of the loft contracting their service, and its that link upon which major sailmakers have built their reputations. The industry has seen it as the wave of the future, and now many other sailmakers-large and small-have silent sewing machines and growing UPS accounts.

except where noted

The flip side of this argument is the need to keep a local loft supported so that the domestic sailmaking industry retains craftsmanship as well as salesmanship skills. This is more than a twinge of sentimentality. Labor market swings occur in shorter and shorter intervals, and losing a domestic trade such as sailmaking may be a short-term gain followed by a long-term disadvantage. Sail lofts may be able to keep the doors open by sending production overseas, but those who actually make sails wont have enough work to keep their profession viable. Today, every decent-sized harbor seems to have one or more resident sail lofts, and we take such sailmaking and repair availability for granted.

String Theory

Sails are a fascinating engineering statement, and when all is said and done, whats sought after is the lightest material possible that will neither stretch nor tear as it withstands the ravages of wind-induced pressure, vessel righting moment, and harassment from sunlight, chafe, atmospheric deposition, and other deteriorating effects. Thanks to modern chemistry, cotton cloth lies well astern, but for several important reasons, even after 50 years, Dacron has yet to be destined for the junk pile. The pros we interviewed for this article remained surprisingly bullish on Dacron, and it caused us to do some research into why the modest polyester fiber still has such a following.

The answer has to do with cost and chemistry, or more specifically, the crossover point where features such as tenacity, flexural endurance, UV stability and resistance to chemical deterioration stack up on a cost-per-square-yard basis. For those looking to stretch their sail-buying dollars, Dacron delivers. But the real value lies in tightly woven high-yarn-count “premium” Dacron, a material that holds its shape and will keep cruisers happy for the long haul.

Those willing to pay more to optimize performance have a wide range of just-out-of-the-lab, high-modulus material options to choose from. In addition, there are engineering differences in how high-performance sails are built. The basic premise is to lighten up the sail where the loads are the lowest, and reinforce the hot spots. Sail designers understand the value of engineering these foil shapes to cope with the load paths that develop in a given sail. The most savvy designers recognize that a static load path diagram is just one snapshot of whats happening in the sail. Take for example the forces influencing a sail during a beat to windward in 20-knot conditions. A finite element analysis (FEA) diagram would depict the stress/strain flow through the sail, and if reinforcing yarns aligned with this energy profile, the sail would be structurally optimized for that given condition.

Unfortunately, sails need to be able to cope with a wide range of challenges, and if we complicate the above example with a wave breaking in the foot of the sail, a very different FEA load path would be depicted. The bottom line is that sails need to cope with a wide range of conditions, and this isn’t solely a concern for racers. Take for example a cruising headsail on a roller furler, one of the most demanding applications of all. The sail is reefed to varied sizes, endures torsion loads, is rolled up wet and sits in the summer sun for weeks on end. At least racing sails can be designed for very specific wind ranges and sea states, where loads are more predictable and when not in use, they are neatly flaked and stowed out of the weather.

In order to achieve high strength and lower weight, high-modulus materials like Kevlar, Spectra, carbon, Vectran, Norths Cuben Fiber, and other ultra-high molecular weight plastics are strung into high-end sails in much the same way that carbon fiber is used in a hull skin. What all of these yarns have in common are mechanical properties that exceed the tensile strength and resistance to stretch of traditional Dacron. These esoteric fibers are by no means the twill of the emperors new pants. They are test-tube innovations that double, triple, or even quadruple the breaking strength of good-old Dacron. Unfortunately, all of the high-tech solutions seem to come with one or more inherent downsides. Some fibers such as Kevlar and Vectran have little tolerance for UV, while other materials-carbon fiber, for example-have a price point just shy of spun gold. The competitive racer is driven toward esoteric yarns because the boats just ahead of him have made the switch, and for those who can afford the stronger, lighter material, there is a proven performance edge.

More than chemistry

Performance is partially based on what fibers your sails are made from, but also influenced by a second pivotal issue: how the sail material is made. At the cutting edge of the industry is sail molding and a membrane approach as exemplified by North Sails pioneering efforts with what it calls 3DL (three-dimensional laminate). In this process, a thermal-setting adhesive film is placed on a shape-controlled male mold, and yarns are towed into position Peter-Pan-like by a sailmaker in a harness. The spiderweb of strings that he tows into place conforms to the sail designers detailed plan for load sharing. Once strung, a vacuum bag and heat-bonding process seals the deal. The resulting seamless main body of the sail maximizes evenness of energy distribution and eliminates stress risers caused by overlapping seams. These sails are great performers, but theyre a big-buck commitment probably best suited to those whose pulse remains steady when their Rolex falls overboard.

Another approach to membrane sails is found on a roll rather than on a mold. Dimension-Polyants D-4 method involves engineering the load-path for a specific sail as they make the cloth in the factory. Its an automated process that tightly controls yarn reinforcement patterns as it builds up on the film or taffeta surface prior to being pressure and heat bonded in place. Once the bonding resin is cured, the sailmaker is sent carefully marked panels that replicate the information on the digital file sent to Dimension Polyant. Pieces fit together like a high-tech, jig-saw puzzle with the sails reinforcement matrix carefully aligned with complex load-paths. Proponents of this approach feel that the yarn trajectories as well as the temperature and pressure control in the laminating process are more tightly controlled.

Advice from the pros

To get a more complete picture of how the trend to offshore sailmaking is impacting everyday sailors, we turned to three trusted voices in the industry. We were particularly interested in what they had to say about high-tech/high-modulus materials and who needs them in their sails.

“Look for a sailmaker not a salesman,” says John Jenkins, the head of the U.S. Naval Academys Sail Loft. Jenkins has been in the trade for over three decades and has designed and built sails for boats ranging from one-design dinghies to 60-footers crossing oceans on a regular basis. Just as important as his engineering and sailmaking know-how is his open-minded perspective when it comes to new products and new approaches to building sails. Hes also not bound by brand spin and market share pressure, so his observations tend to be focused on the end-user rather than the bottomline. And the latter is why we lead off with his opinions.

When we asked Jenkins what sail material is best for the cruising sailor, his unequivocal response was, “Youve got to go with Dacron.” There was no hesitation, no caveat. “High modulus materials are lighter and stronger, but they are also more fragile and have a very short lifespan. These esoteric materials have a valid role for a racer, but when it comes to cruisers, Dacron should dominate.” He went on voicing an opinion we agree with, “high-modulus-yarn-laden membrane sails are a fine product for top-tier competitors with a big budget, but theyre not cost effective for the cruiser looking for longevity, UV stability, mildew avoidance, and the ability to endure roller-furling harassment.”

Jenkins cruisers sailcloth of choice is either Dimensions high-quality Dacron (polyester) square weave or Challenges Marblehead weave. The latter is a cloth comprising DuPont 52 and Honeywell IW70 yarns. Both materials are light on resin and pack lots of thread into every square inch of cloth. He also prefers woven Dacron for its mildew resistance and uses a fill-oriented weave such as CX-9 for higher aspect ratio headsails.

Quantum Sails designer and material guru Doug Stewart knows the performance value of carbon-fiber packed D-4 membrane sails, but hes also quick to reiterate many of John Jenkins candid comments. He stressed the importance of discerning just how competitive a potential customer happens to be, and despite being a serious advocate for technology, he too was quick to endorse the value of tightly woven premium Dacron as a cruisers top choice. He saw laminates playing more of a role in larger boats where sail weight becomes a big issue, but pointed out that mildew accumulation and delamination, though significantly reduced with new approaches to bonding, are still a concern to cruisers.

Carol Hasse, owner of Port Townsend Sails, is the quintessential cruising sailors advocate, and is always looking to build quality and long term reliability into the sails she makes. Her vision includes the insight that “at sea youre a long way from your sailmaker and the extra care that goes into the initial design and construction will pay off in the long run.” This is especially true on the rough nights at sea when the reefing process starts just a little too late. From Hasses point of view the right choice in material is a premium woven Dacron that affords a little less on the performance side of the ledger, but a lot more on the handle-ability, durability, and longevity.

Conclusion

The bottom line for the consumer is part price point and part utilitarian. The big questions are how much sail trimming are you willing to do and will you take advantage of molded membrane sails. If youre a cruiser, you may be better off with top-quality woven Dacron that offers good sail shape and an excellent lifespan. And in the opinion of three very skilled sailmakers, your best bet is indeed a step back to the future.