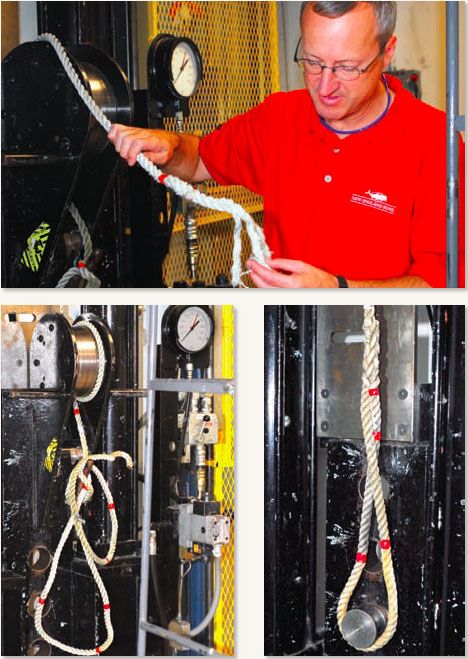

To evaluate the effect of sunlight and weather on nylon cordage, Practical Sailor, with the help of New England Ropes, tested several weathered 10- to 12-year-old dock lines to destruction. The New England Ropes testing lab contained a large, dual vertical-piston hydraulic ram with a jig arrangement that allowed a line to be positioned between two attachment points that moved apart at a slow and uniform rate. Because we had a variety of lines, some with spliced ends and others with free ends, we used two differing pieces of termination hardware. The free ends were given a single turn around a large winch like drum (right, below) and made fast to a conventional cleat. Through the use of the unit’s spacing adjustment, we were able to keep the chafed ends of each line out of the test. When securing a line with an eye splice, the drum and cleat fitting on the jig were replaced with a piece of hardware that allowed the spliced loop to be held on a smooth, cylinder-shaped attachment (far right).

A load cell linked to a computer tracked the strain imposed by the jig. The amount of elongation in the tested ropes prior to destruction was impressive, but it was still shorter than the 25-percent maximum elongation that new nylon cordage will exhibit prior to failure.

Nylon Dock Line Breaking Strength

| SAMPLE NO. | SIZE | FAILUTE POINT TESTED LINE | BREAKING STRENGTH NEW LINE | PERCENTAGE* |

|---|---|---|---|---|

| 1 | 1/2 inch | 1,893 pounds | 7,500 pounds | 0.25 |

| 2 | 1/2 inch | 1,892 pounds | 7,500 pounds | 0.25 |

| 3 | 5/8 inch | 3,493 pounds | 12,000 pounds | 0.28 |

| 4 | 5/8 inch | 6,105 pounds | 12,000 pounds | 0.51 |

| 5 | 3/4 inch | 5,861 pounds | 16,500 pounds | 0.36 |

| 6 | 3/4 inch | 6,288 pounds | 16,500 pounds | 0.38 |

| 7 | 3/4 inch | 5,678 pounds | 16,500 pounds | 0.34 |

| *Percentage of original breaking strength remaining, as tested. |