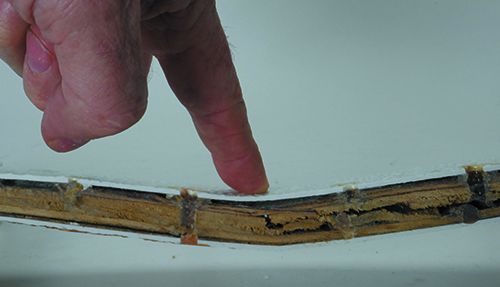

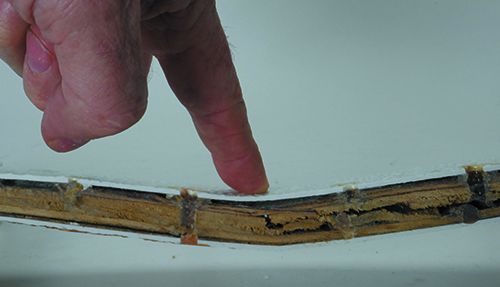

Our repair process varied by product and was based on the manufacturer’s guidance.

For epoxy, we used 10 injection points on each coupon, in two rows on 1.5-inch centers. Because the epoxy does not penetrate far, more would help, but that’s a lot of holes.

For Gorilla Glue, we used a single row of five injection points because we thought the moisture-induced expansion would cause the Gorilla Glue to spread farther. Although not as strong as epoxy, the Gorilla Glue foam is very high density and is much stronger than injection foams

Following the Inject-a-Deck guidelines, only three injection points were needed for a 10-inch sample (4-inch spacing). Because of the strong expansion, this was more than enough.