When making your own modified soft shackle, shaping your own dog bone is part of the fun. A wooden dowel did surprisingly well as a dog bone, and no doubt a hardwood dowel would be up to the task, but 6061 aluminium is a better choice for the do-it-yourselfer. You don’t have to worry about rot or other deterioration, and corrosion won’t be a major issue since the aluminum is not in contact with other metals that might set up a galvanic cell that leads to corrosion.

One manufacturer has gone so far to offer titanium dog bones, but the added tenslle strength is superfluous, since the Dyneema line that forms the shackle will part before the dog bone itself. Aluminum is also easier to machine.

You can use a lathe, drill press, or even a handheld drill with a file to create sufficient taper. The groove should reduce the diameter by about 15 to 20 percent.

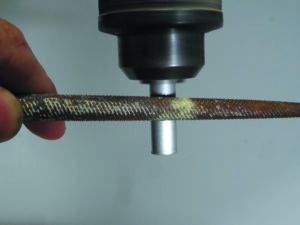

1. Lines on the dog bone mounted in a drill press define where to file.

2. A vice or your hand can be used to hold the file as the rotating aluminum dowel is run back and forth across it.

3. To prevent abrasion, polish the dog bone with a minimum 200-grit abrasive. You can make it smoother for a more “professional” look, but 200-grit is adequate to prevent abrasion.