For this comparison of synthetic teak options, our first concern was ease of installation. The manufacturer typically carries out the hardest part-welding the panels together to achieve the correct dimensions. The ease of gluing our test panels to a simulated fiberglass deck was similar for all five test products. The difficulty of your own project will depend on how much work the manufacturer does in terms of measuring, assembling, and fitting the panels.

Material thickness and flexibility also were of interest. Each test panel was measured with a micrometer gauge giving thickness in decimal inches and checked for flexibility. PlasDeck was the thinnest and most flexible; Marinedeck was the thickest and least flexible; and the other three fell somewhere in the middle. Flexibility will affect the ease with which you can mold the strips or panels to the curves of your deck.

Testers checked the undersides of the panels, presuming that a bottom with more tooth might bond better. Dek-King has the most texture with T-shaped ridges; Flexiteek has smaller ridges, and Permateek has a very rough bottom. The PlasDeck bottom is the smoothest, and Marinedeck is semi-smooth. It will be interesting to see whether there are any adhesion changes after the test panels spend some time out in the hot Florida sun.

Texture, Color, & Nonskid

The panels topside texture was of more interest to us since a boat deck sees plenty of barefoot traffic. The softer the deckings feel, the easier it will be on knees and feet. Marinedecks cork-based material was the softest and smoothest, and Permateek was the roughest. PlasDeck was medium coarse while Dek-King and Flexiteek felt the most like natural teak.

When it comes to synthetic decking, variety is a selling point. Permateek offers 10 decking color options, while Dek-King and Flexiteek both come in five deck colors, and PlasDeck offers nine. Most of the colors are simulated shades of teak, ranging from new to weathered gray. Marinedeck comes in just the one cork color. Most makers offer multiple caulks, usually black, white, or grey. PlasDeck has the widest range of caulk options, including glow-in-the-dark caulk.

Perhaps one of the most important characteristics of a deck is its nonskid performance. We used the same homemade traction-testing jig that we use for testing shoe grip to gauge the test panels nonskid action when inclined at measured heeling angles. A Sperry Topsider deck shoe with a 4.5-pound weight was placed on each test panel, and the panels were raised until the shoe began slipping down the grade-wet and dry; the accompanying Value Guide shows the incline at which skidding took place.

The dent resistance test was revealing. We dropped a carpenters plumb bob with a pointed end from 6 feet and observed the holes made in each material, and then dropped an eight-pound mushroom anchor from 4 feet and noted any resulting dents. The natural wood did the worst, showing obvious puncturing and denting, even after 24 hours. Some synthetics that looked badly dented returned to normal after a few hours. Both Dek-King and the cork Marinedeck showed obvious holes and dents initially, but the blemishes smoothed out after a couple of days.

Stain Resistance & Heat

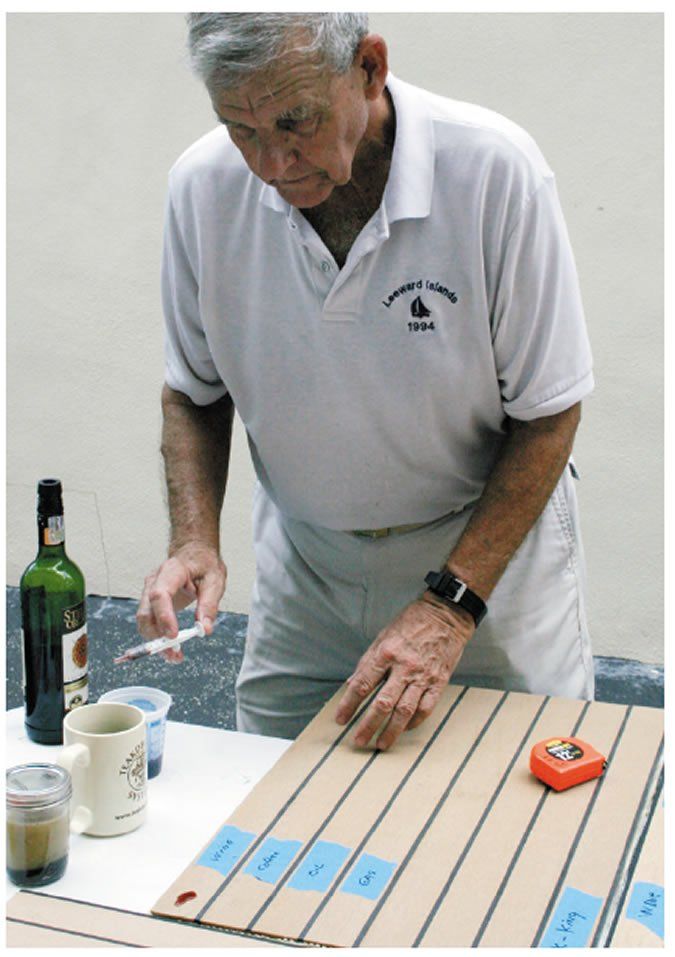

For the stain-resistance evaluation, testers soiled the panels with dirty oil, gasoline, coffee, and red wine, and rated the effects after 15 minutes and again 24 hours later, after cleaning with Palmolive dish soap and water. Harsh chemical cleaners or solvents, such as acetone or bleach, are definitely not recommended.

Darker materials hid stains better. PlasDeck and Permateek were the easiest to clean and showed little oil stain after a week. Natural teak showed the darkest oil stain. All of the stains came up, some were just easier.

To compare surface temperature, we left the test panels out in the mid-day Florida sun for six hours, and then gave them a subjective feel test for 30 seconds; testers also used a Fluke 62 mini-infrared thermometer to check surface temperature. In the end, the only firm conclusion was the obvious one, lighter surfaces are cooler, and less-dense materials like cork are better insulators.

Cost & Durability

Another major factor when planning to replace a deck or starting from scratch is cost. We found that with synthetic decking, costs may vary considerably, even from the same manufacturer. Costs per square foot will depend on the size and complexity of a project, how much trim and border is necessary, and how much work the customer does. Some makers have a standard-grade or a premium-grade material, and some materials, especially natural teak, are available in different thickness. The costs shown in our table are a rounded median of those available from each supplier.

The biggest question mark for us was long-term durability. All manufacturers promote the stability of their material and colors, and the need for periodic maintenance. Practical Sailor plans to leave the test panels out in the Florida sun and rain, and will re-evaluate them over time to rate durability, adhesion, and color retention. All five manufacturers offer five-year warranties on the basic material.