Its not the gusty trade-wind conditions and mile-making reaches that I recall most about the Indian Ocean, its the failure of Wind Shadows rudder and the look of the useless appendage streaming parallel to the surface that left a lasting impression. Steering with a jury rig the remaining 300 miles to the island of Mauritius gave me enough time to curse spade rudders and those who built them. Over the years since, Ive learned a lot more about steering systems and now concede that spade rudders have redeemed themselves as valid ocean-going steering appendages. However, what has replaced them in the bulls-eye of my ire is the indiscriminate way in which metal is used in building boats, especially in places on the boat that are out of sight and supposedly will never be in contact with sea water.

The crux of my Indian Ocean rudder problem had nothing to do with the original design done by Bruce King (see “California Classic: Ericson 41,” January 2007), which included a rugged, stainless steel tube stock with ample structure to handle the twisting loads. A subcontractor hired by the builder modified the plans and saved two feet of stainless steel tube by welding a mild steel plate to the shortened stock just after it entered the blade. The flex associated with the working loads of the rudder cracked the poorly engineered redesign, and water entered the foam core causing the dissimilar metal welds and mild steel plate to rust. Eventually, the welded plate failed. Had the contractor followed the designers original plan and used about $100 worth of additional stainless steel, the problem and the risk at which it put myself and my family would have been averted.

Some builders erroneously felt that encapsulating ferrous metal in a laminate would keep moisture out, and so there was no reason to use more costly stainless steel. Many rudders supported by skegs have mild steel plates encapsulated in their centers. The builders assumed that since the metal would be totally coated in resin and glass, it would be immune to corrosion. Unfortunately, the expansion rates of mild steel and fiberglass reinforced plastic (FRP) are different and polyester resin adheres poorly if at all to metal. The resulting delamination between the two surfaces is just the start of a very big problem.

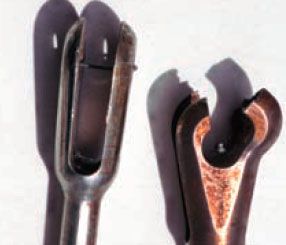

Capillary action can move a liquid through very small spaces, and as soon as the mild steel core gets wet, it starts to corrode. In regions with below-freezing temperatures, further damage is caused by the expansion associated with a liquid turning into a solid. The coup de grace is steels physical behavior when oxidation takes place. Not only does the corroded metals reinforcing value eventually diminish to zero, but it will actually expand as it turns from a metallic state to an oxide. This expansion can rupture laminates and cause appendages like rudders, skegs, or chainplate supports to fail.

Merlot is a 19-foot Cape Dory Typhoon that my wife and I love to daysail, and weve gotten to know the boat inside and out. Cape Dorys reputation as a builder of quality boats is mostly deserved, but in several crucial areas, there are glaring shortfalls that demonstrate why sailors need to be vigilant both on and off the water. A classic case in point came to light during a breezy afternoon beat when a loud snap announced that one of two bolts holding the starboard chainplate fitting had failed. A quick tack and hasty work dousing the sails kept the rig in place. My preliminary inspection of the chainplate support located in a hard-to-reach area under the deck left me with an alarming hand full of cornflake-like rust.

A closer look at the area revealed that the builder had decided to bond mild steel backing plates into the sheer structure to support the chainplates. Over the years, the backing plates disintegrated and destroyed the chainplate support. Perhaps this was done on only a few of the long run of Cape Dory Typhoons, but whatever the case, the couple of bucks saved by not using stainless steel for the backing plates, added up to a difficult do-it-yourself repair, or a sizable yard bill that would have grown logarithmically had the rig gone over the side.

During the decade I ran a boatyard, I had the chance to see numerous examples of metallurgical mistakes. A couple of near sinkings were the most dramatic examples of how an engineering shortcut can play out in the long run. One Swan 44 had a persistent leak that turned out to be coming from the stern tube, which was composed of two different alloy stainless steel pipes welded together. The builder had resorted to this hybrid stern tube to solve a problem: The shaft log and the cutlass bearing diameters were different. The potential for corrosion was exacerbated when the builder laminated the less noble portion of stainless tube and the weld itself in a neat wrap of fiberglass laminate.

This three-fold engineering faux pas was like a time bomb placed in the bilge. The first mistake was that two different alloys were welded together and immersed in sea water, inviting galvanic corrosion. Secondly, insult was added to injury when both the less noble metal and the weld were encapsulated in fiberglass, limiting oxygen to the surface of the metal. And finally, there was an assumption that the adhesive quality of the resin to metal bond would act as a long-term water seal.

Using a pneumatic chisel and an inordinate amount of labor, our smallest technician squeezed into the bilge and removed the errant stern tube. The encapsulated portion of the two-piece pipe looked like a cylindrical piece of Swiss cheese. A composite FRP stern tube replaced the original and eliminated the problems associated with submerged stainless steel and its tendency to become less noble and thus more prone to corrosion underwater.

Another European boatbuilder bonded a brass, not bronze, pipe stub into the hull skin in the boot-top area of a custom designed 46-foot ketch. He apparently rationalized that the sink drain to which it connected would be above the waterline and so didnt require a proper through-hull with a seacock. The designers weight calculations erred greatly on the light side and the boot top had to be raised, so the sink drain fitting ended up a few inches below the waterline. The brass was less noble than nearby bronze through-hulls, and galvanic action went straight to work. It took a few seasons, but one night, a vigilant launch operator noticed that the 46-foot ketch was down on her lines. Only a quick response with a plug stopped the boat from sinking. The submerged brass sink drain tube had failed, immersing the engine, generator, batteries, and all the gear and supplies in lockers below the berths. The small savings associated with ignoring the need for a proper through hull and valve turned into a big repair bill.

Incidentally, American Boat and Yacht Councils Standards define “below the waterline” (and so requiring a proper seacock) as any area of the hull that is immersed when the boat is heeled to the point that its rail first contacts the water.

Early Asian-built sailboats had hardware and fittings especially tangs and turnbuckles that came from backyard foundries where little or no concern was given to the mechanical and chemical attributes of different alloys. Their approach to marine metals was based more upon how the metal looked, rather than how it would hold up under load. Voids and alloy problems in cast bronze and stainless rigging components became so widespread in the 1970s that many riggers told new owners to change the turnbuckles and toggles before they sailed their new boats. Even though the hardware looked like components made in the U.S. or Europe, the castings were far inferior. In that time period, Asian quality control during the alloying of non-ferrous metals was primitive at best, and the old adage “all that glitters isn’t gold” certainly held true for silicon bronze, an alloy thats usually a superior choice for rigging hardware or submerged applications. Slight variation in the content and purity of the alloying metals will taint the recipe and change the metals mechanical as well as corrosion resistance characteristics, so quality control is imperative.

Little shortcuts can have serious ramifications, so the new owner of an older Asian-built boat would be smart to pursue a rigging hardware upgrade. Replacing the turnbuckles and toggles with U.S. or European product is money well spent. Older Chinese-built boats, in particular, have been plagued by unreliable metal components.

Circumnavigators and three-decade live-aboard cruisers Al and Beth Liggett had a box full of fasteners and hardware that died an early death aboard their able Perry-designed cruiser Sun Flower, which they had built in the Orient. Cyclic loading and working strains are expected to eventually wear out components, but the life span of a fastener or piece of hardware is drastically shortened if the metallurgy has been inconsistent.

This is anything but a xenophobic bias. Ive spoken with riggers across the country who have alluded to a disturbing trend associated with Chinese hardware and have shown me boxes filled with fractured turnbuckles, corroded tangs, and what-not collections of broken bits and pieces. Marine metals were the Achilles Heel of these imported boats from the 60s well into the 80s when savvy builders started shipping U.S. and European hardware to China despite the cost.

The metals problem has manifested itself in much more than sailboat rigging. Prop shafts, carbon steel fuel tanks, underwater running gear, and cast steering quadrants are just a few components that often fail to meet Western standards.

A question many long-distance cruisers have to ask themselves relates to their vessels unseen keel bolts and how the stainless steel is holding up after several decades of immersion. Its a question that can only be answered by unbolting the ballast and separating it from the FRP keel stub, a costly but worthwhile expenditure for those headed across an ocean aboard a 25-year-old sailboat, regardless of where the boat was built. And while youre at it, drop the rudder to check the stock and look for signs of other problems.

Every owner occasionally needs to do a little metal prospecting aboard his own boat; and all it takes is a good magnet, a bright flashlight, a magnifying glass, a mechanics mirror, and a few simple hand tools. The objective is to search out the metals hidden in the hard-to-get-at recesses and visually inspect them for cracks and corrosion. When the rig is unstepped, go over every fitting and piece of hardware with a fine-tooth comb. While youre at it, go back to the boat and carefully inspect the mast step. Scrape the bottom paint away from through-hulls and look for signs of pitting and pinkish, porous discoloration a sure sign of galvanic corrosion. Keep in mind that malleable silicon bronze is a wonderfully durable metal, and often fasteners and hardware that look green, oxidized and slightly deformed continue to do their job. However, stainless steel can reveal very few symptoms of fatigue or weakness prior to breaking. This means a close inspection is as important as a commitment to regularly replace key components as they reach the end of their life cycle. The experts at Navtec use a 10-year benchmark as a general rule of thumb for standing rigging aboard boats that are raced. Surprisingly, vessels doing extensive long-distance ocean cruising go through a different but even more demanding set of cycle loads. Many riggers feel that theres about one circumnavigation (approximately 30,000 miles or five-10 years) worth of life in every set of standing rigging.

The bottom line is to beware of stainless steel, its origin and any surface symptoms that may indicate deterioration. “Stainless steel” covers a wide range of alloys, all of which behave badly when submerged. By replacing zincs regularly, even if there seems to be a little metal left, and making sure that stray DC current isn’t turning your boat into a metal plating test tank, youll increase the alloys life span.Look closely at your boats rudder and be suspicious of any cracks on the FRP skin and signs of rust oozing from the bottom of the blade.

In short, get to know your boat inside and out, and develop a preventative maintenance strategy thats at least one step ahead of the metallurgical pitfalls.

The price of nickel, a key ingredient in marine-grade stainless steel, more than doubled in 2006, and marine hardware manufacturers are already passing 15-20 percent price increases on to consumers. Although market watchers believe that nickel inventories have now stabilized, there’s little chance that the prices of stainless steel gear will go down in the near future. And as the rising cost of nickel makes substitition more tempting, Practical Sailor has little confidence that that the quality of stainless steel products coming in from China will improve. With the hopes of identifying the best quality hardware, we will be undertaking a test of stainless steel and other metal fasteners later this year.

bronze seacock remained in

service for almost 50 years.

High-grade silicon bronze

can look green and awful and still retain most of

it’s mechanical properties,

unlike stainless steel which

can appear shiny right up

until the moment it breaks.

I hope Mr. Nicholson will make a book of his articles. They are really valuable.

Looking forward to more.

I like this article and note that there is already a book on the choice of metals to be used and covers more than just corrosion: “Metals In Boats” by Vyv Cox. Worth getting a copy. Or you can look up other testing he has done on chain or chain C-link connectors for example at http://www.coxeng.co.uk . Vyv (a metallurgist, like me) has now retired but think his son continues the business.

Andrew

“Genial Bee”