Epoxy fillers can be used to fix surface imperfections or for reshaping appendages like keels and rudders to make them more efficient. The smaller the surface imperfection, the less viscous the fairing compound should be. When filling deeper holes or voids, check the manufacturers recommended thickness per application. It may take two or more coats to achieve the necessary thickness. Applying filler too thickly can cause it to sag or will result in an incomplete cure.

1. Prior to troweling-on any epoxy filler, you need to follow a few important steps to prepare the surface. Begin by washing the entire repair region. Premature sanding or spot grinding will drive dirt, paint, and oily, waxy chemical contaminants deeper into the substrate. Take the washdown process seriously.

2. The next step is to expose all damaged or deteriorated laminate and taper the edges so that theres a smooth bevel toward sound, well-adhered gelcoat. If layers of structural FRP material have been damaged, they need to be replaced. Filling and fairing is a non-structural, cosmetic cure that doesn’t add strength. Before filling any cracks and delamination in high-stress areas (keel-to-hull junction, chain plates, rudder, etc.), you should have the area evaluated by a professional surveyor to make sure these cracks are merely superficial. Once the surface has been sanded, vacuumed, or blown clean, wipe down the surface with the manufacturers recommended surface cleaning agent.

Some solvents are volatile chemicals such as Interlux 202; others are green cleaners such as MAS Bio-Solv. Allow time for the solvent to evaporate. The surface should be completely dry before applying putty or priming the entire area to be repaired.

Some manufacturers recommend a thin coat of two-part epoxy primer prior to fairing with their filler. Its best if you use the epoxy primer recommended by the manufacturer of the finish coat material you intend to use.

3. The next crucial step in the fairing process is measuring out the right amount of the two-part epoxy prior to thoroughly mixing part A with part B. Some products are 50/50 blends, while others are a trickier 2-to-1 or even 3-to-1 blend of base and activator. Inaccurate measurement or too little mixing can lead to an incomplete or uneven cure. The ambient temperature accelerates (or slows) cure time, so be sure that you don’t mix more than can be used in about three-quarters of the listed working time.

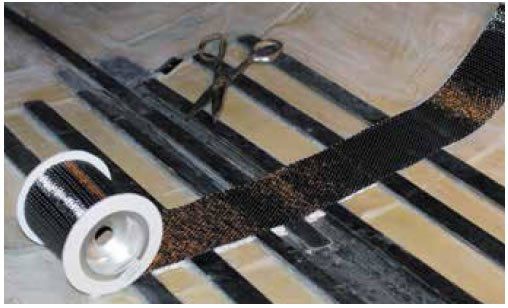

4. Strive to avoid excess epoxy application. A rushed application adds up to an exponential increase in sanding. Youre not chiseling a sculpture; youre smoothing an imperfection. The closer you can match the desired surface contour, the less sanding. Required tools will include plastic squeegees, various size and flexibility putty knives, a couple of single-sided razor blades to remove excess filler, and plenty of disposable gloves to keep the filler off your hands.

5. When you get to the sanding phase, its important to keep two goals in mind. The surface should be smooth, but it needs to match the contour intended by the designer. Avoiding unwanted high and low areas requires the right tools, the right fairing product, and plenty of patience.

When fairing large areas, you can use a large-diameter disk sander equipped with a soft pad. Be gentle. Start moving the sander before pulling the trigger and carefully keep the disk only slightly inclined (nearly parallel) to the surface being sanded. Switch to a smaller rotary orbital, vacuum-aided sander or perhaps a pneumatic DA sander for finer work. Do some trial runs on the surface of an old FRP dinghy before tackling a topside repair on your pride and joy.

Use increasingly finer sandpaper as you go and progress to gentler tools as you approach the desired smoothness. Eventually, put aside the power sander and pick up the hand-powered longboard or sanding blocks for the final phase of the fairing process. The 50- to 80-grit sanding ritual leaves a surface ready to be epoxy-primed and then fine-sanded prior to finish coating. The rule of thumb remains: The shinier the final finish, the more effort must be lavished on the filling, priming, and sanding process.

6. Once the putty has been sanded fair, another coat of epoxy primer is applied, and the surface is evaluated. In some instances, there may be a need to repeat the process. Keel shaping often means more longboarding and less machine sanding. The goal is to develop a new contour, and making the surface compliant with a template means lots of longboarding and using a filler such as Interlux 830.