Photos by Ralph Naranjo

288

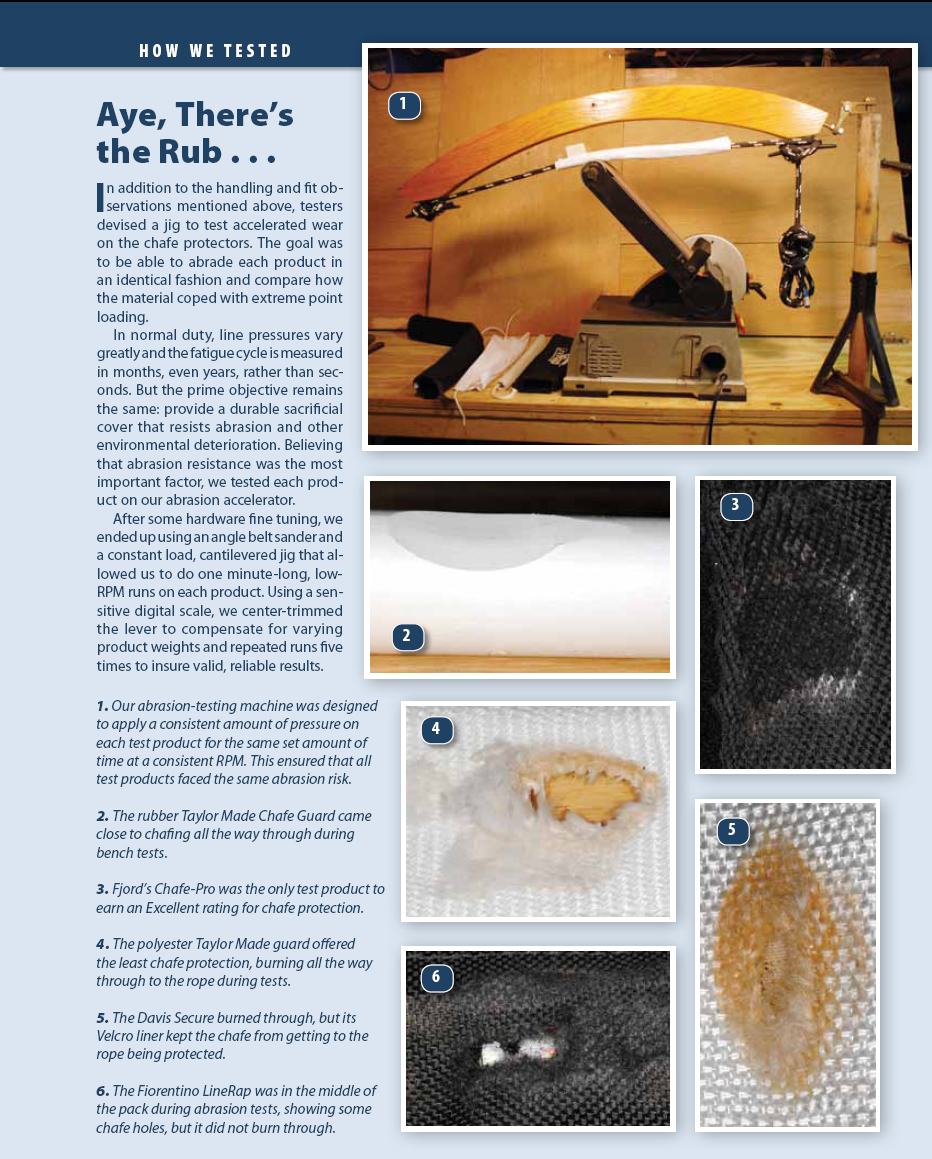

Engineers are quick to point out the downside of bending a tensioned line over a hard point—which is exactly what happens at every cleat, chock, and anchor roller on a moored boat. The result is a cluster of compromises that make line failure at the point of contact much more likely. These rope-degrading factors are all directly linked to the point load and pressure induced by the contact.

314

For example, rope fibers are more stressed in the outer part of the bend radius than at the inward most point, but this often becomes a moot issue because of the even more damaging internal filament friction and line abrasion. This friction and abrasion are linked to heat build-up and physical damage to the surface in contact with the metal cleat, chock, or rail.

Padding can help prevent or at least minimize rope damage caused by hard edges. At the heart of a good chafe-protection plan is a sacrificial layer placed between the hard surface and the softer nylon, polyester, or other type rope. Such a boundary layer shifts the chafing action to the material wrapped around the line, sacrificing its integrity rather than that of the line. However, this padding can also act as a thermal insulator, increasing the heat generated by internal stretch. In our cordage tests at New England Ropes (PS, December 2007), we found that intra-strand filament friction linked to rope stretch caused heat buildup that resulted in filament melting.

A corollary to this work is relevant when it comes to approaches to chafe protection. And the bottom line is the importance of avoiding the use of chafe gear that “bottles up” rope-generated heat. It’s important to maintain thermal transfer and allow heat created by a working dock line, mooring pendant, or anchor rode to dissipate into the surrounding structures and the atmosphere. Failure to do so is the very reason why a spate of mooring-pendant breakages in the 1980s led to the end of the once-common practice of using PVC tubing as a chafe protection. The tubing-sleeved rope was placed at key points such as chocks, bow rollers, hawseholes and in mooring thimbles. As the nylon rope worked, filament stretch created heat, and it was unable to escape because of the tube’s insulating effect. The resulting line rupture occurred at lower tension due to the effect of higher internal temperature.

So when shopping for—or making your own—anti-chafe gear, there are a few key things you should keep in mind. First, make sure that the material will fit your chocks and will extend far enough to prevent rails and other hardware from becoming a secondary source of abrasion. We also found that there needs to be a rugged means of preventing the gear from sliding away from where the action happens to be. Some people duct tape their anti-chafe gear in place, a temporary, in-a-pinch solution. Some products come with Velcro hooks on the inside to anchor the chafe guard to the rope itself. Others use hook- and-loop technology only to close the two halves of the chafe gear around a line. When the chafe protection is left on the line permanently, it makes sense to lash or sew the ends in place.

What We Tested

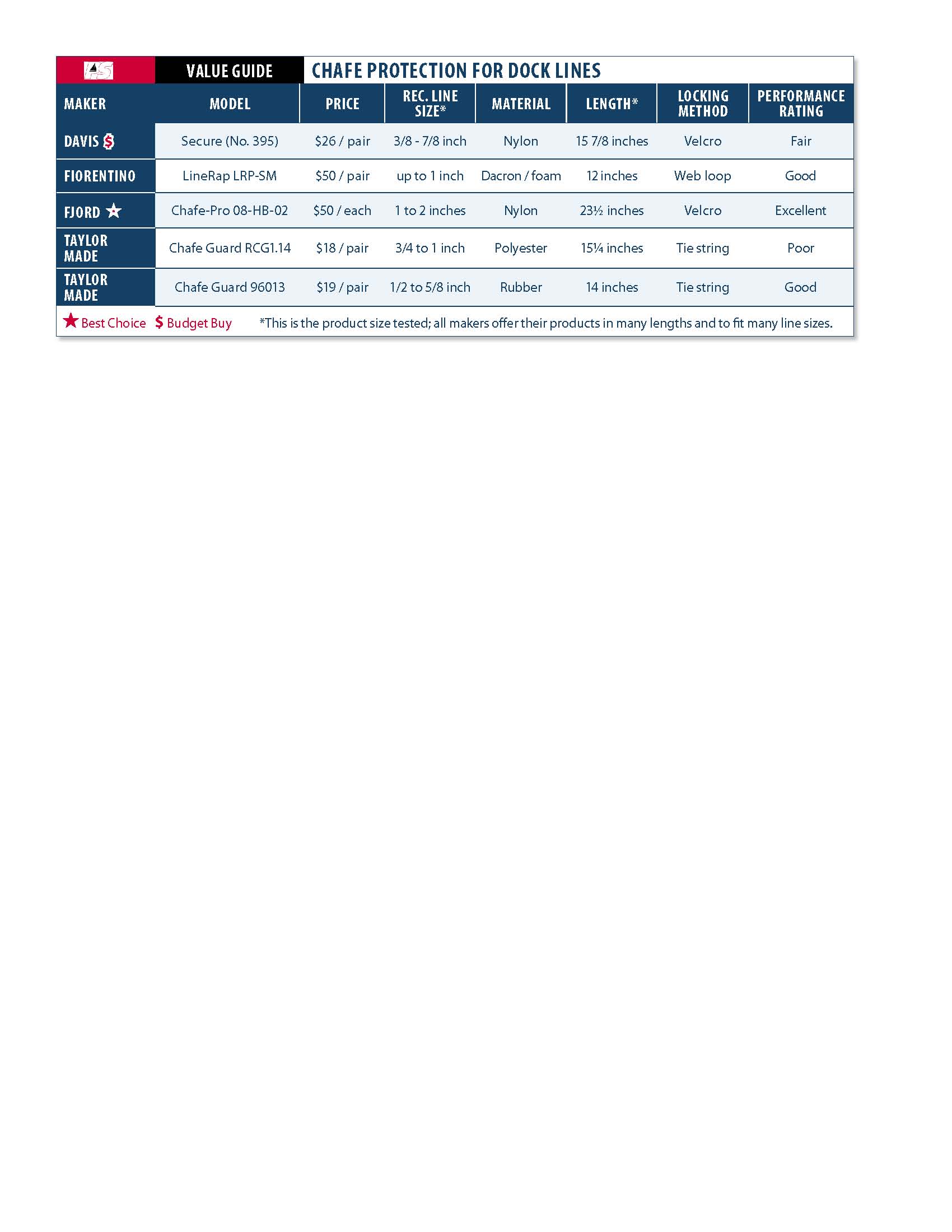

For this test, we evaluated five commercially made products marketed for chafe protection on and around boats. The anti-chafe gear included products from marine accessories-maker Davis Instruments, Para-Anchor manufacturer Fiorentino, the North Carolina-based Fjord Inc., and Taylor Made.

We ranked the five over-the-counter chafe protectors we tested for this report as light, medium, and heavy duty. The tougher the chafe problem, the more heavy-duty the solution and the bulkier the products tend to be. The Davis and Taylor Made single-skin webbing products were convenient and easy to use but not as abrasion resistant as the other three test products.

Fiorentino’s LineRap had a tough Dacron double-layer design, and Taylor’s traditional rubber chafe protector fell into our medium-duty designation, showing more resistance to chafe than the light-duty alternatives but doing so with two very different materials. We pegged the Fjord Chafe-Pro as the heavy-duty entry, and it lived up to expectations as the most abrasion resistant.

Davis Secure

This simple-to-use chafe guard is comprised of nylon webbing with Velcro sewn to the other side. Installing the Davis Secure (No. 395) involves rolling the line up in the webbing, which proved to be a quick and easy way to get chafe protection in place with the least possible fuss. The hooked Velcro surface locks into the fibers of the three-strand or braided line, and there was no need to follow up with any tieoffs or other locking effort to keep the chafe gear where it belonged.

The moderate weight of the nylon webbing affords fair abrasion resistance, but testing did reveal that durability directly correlates to the weight, layering, and surface coating of the materials used. The abrasion test cut through the webbing and was abrading the Velcro hook layer that backs the webbing, but it had not yet holed it.

This would be a handy piece of anti-chafe protection to put on roller-furling genoa sheets when the boat is left for a week or more. Just roll the Davis Secure chafe guard at the point where the sheet presses against a shroud and prevent costly premature sheet replacement. This would also keep users from releasing the sheets and moving them forward, clear of the shrouds—a bad habit that could result in the sail unfurling and being destroyed in a storm.

Bottom line: An easy-to-use anti-chafe system, the Davis Secure gets PS’s Budget Buy pick for light duty.

Fiorentino LineRap

A manufacturer of sea anchors and rodes, Fiorentino has first-hand experience with line-chafe issues, and the company has adapted its RodeRap design developed for sea anchors into a shorter version dubbed the “LineRap.”

The trademarked Sun Protector Dacron sleeve is a supple chafe guard with open-cell foam padding. The sleeve’s Velcro seam makes attachment quick and easy, though the relatively short length and large-diameter opening make the product seem more appropriate for larger diameter lines and single-point chafe concerns. However, the designer intentionally provided this more open approach to increase line cooling—a definite plus, but there are other factors to consider.

Testing has shown us that during rough weather, chafe gear on dock lines, mooring pendants, and anchor rodes tends to bunch and move along the rode, often working its way out of a chock or hawsehole. LineRap has a single, sewn-in webbing eye at one end of the chafe guard that allows a lashing to secure the product to the line being protected or to a fixed point on the boat. Lashing ability at both ends would be of more value, in our opinion.

Our abrasion test showed that the double layer of Dacron was tough, and although the aggressive test gear did cut through one layer, the equally thick back layer was completely intact. What testers found disappointing, however, was how easily the guard’s open-cell-foam guts sheared. According to Fiorentino, the company uses open-cell—rather than closed-cell—foam because it provides more cushioning, is more flexible, and bends easier. “Flexibility is important when placing the chafe guard in chocks and fairleads and allows the guard to shape itself around a sharply bent rope,” Fiorentino researcher Zack Smith explained. “We believe our foam does the job of cushioning the load and distributing force across the fabric more evenly.”

Bottom line: Testers like the Fiorentino LineRap’s design and it had Good abrasion resistance, but it fell short of topping the Chafe-Pro.

Fjord Chafe-Pro

The Fjord Chafe-Pro (08-HB-02)—a patented, heavy-duty nylon webbing and Velcro system—has gained wide acceptance among professional mariners, and as we found out in testing, it lives up to its name. Fjord’s commercial product “offers the kind of chafe protection you want when the chips are down.”

The longer-length, heavier-weight, quadruple-stitched webbing and double-locking Velcro end point make this commercial product a cut above the competition, in our opinion. Despite its bulkier appearance, the Chafe-Pro was easy to install, took an angle change in stride, and fit into chocks with ease.

The manufacturer recommends the Chafe-Pro 08-HB-02 for 1- to 2-inch lines; however, in our testing 3/4-inch nylon line, and even 5/8-inch nylon or polyester line, was well protected when rolled up in the Chafe-Pro 08-HB-02. The guard’s grabby Velcro line-attachment system enabled it to stay in place on these lines much better than those products with only a single tie-on attachment system, even those rated for smaller lines. It snags and holds the line, leaving no need for it to be tied on.

Nearly defying the bite of the 50-grit belt sander, Chafe-Pro’s urethane-coated, black ballistic nylon went away from our hungry test machine with all layers intact. In fact, at the point where the abrasion was focused, there was only a slightly scuffed surface.

Bottom line: The commercial, double-layer Chafe-Pro combines rugged protection with a user-friendly design that’s easy to install and lock in place. It gets the nod for PS Best Choice. Priced at $50 per guard, the 08-HB-02 was by far the most expensive product we tested. However, Fjord offers similar products in its recreational line (for line sizes 3/8 inches to 1.5 inches) for about $45 per pair. Look for a test of the recreational products in a future issue.

Taylor Made Chafe Guard RCG1.14

The Taylor Made Chafe Guard (RCG1.14) is a 16- by-4.75-inch length of single-skin polyester webbing with strips of Velcro along each side. Each end has two holes and short stuff is supplied to lash the nylon Chafe Guard in place. This system does not incorporate Velcro on the inner surface as a means of locking the line to the webbing.

In testing, we noted that the line did slide inside the chafe guard, and the webbing also slid against the chock. The former can be minimized by following Taylor’s recommended means of attachment: lacing the line through rope strands or braid and also lashing around the webbing itself. Being able to keep anti-chafe material from working its way out of contact with the offending hardware is as important as the material’s toughness.

The abrasive test took its toll on the Chafe Guard, wearing a hole through the material faster than any other test product. We recognized the brutal surface destructiveness of our equipment, but the fact that overall results ranged from complete to minor damage validated that some products were more resistant to heavy abrasion than others.

Bottom line: The polyester Taylor Chafe Guard is vulnerable to heavy point loading, but it’s easy to install, and from our perspective, it still has merit in situations where very light-duty chafe protection is desired.

Taylor Made Chafe Guard 96013

Taylor Made has long provided rubber-boot type Chafe Guards that have been marina favorites for decades. Their longitudinally split, overlapping attachment design allows them to be easily slipped over docklines, and a hole is placed at one end for the lashing line that is provided. Because of the rigid nature of the product, there’s no tendency to bunch up, and a single-point attachment takes care of the bidirectional line movement. However, one drawback to rigid chafe protectors is that heat buildup can become an issue.

Rubber dust flew as the 96013 Chafe Guard rested on the spinning 50-grit sanding belt. Thanks to the substantial wall thickness of the material, the product remained intact, and no penetration occurred.

Bottom line: The rubber chafe guard is worth considering if you prefer rigid protection, but it was not testers’ favorite in this group.

Conclusion

The best type of chafe gear to rely on in a storm is the one that has high resistance to abrasion, doesn’t act as thermal insulation causing heat build up in the line to increase filament failure, and can be easily installed—even when the line has already been deployed.

Just as important is the anti-chafe gear’s ability to remain in place, regardless of how vigorously lines tense and relax as they pass through or over a piece of hardware. Boats left on moorings or tied to floats and docks are usually unattended when the worst weather strikes. Time and again, lines fail because perfectly good chafe protection worked its way up or down the line and the abrasion buffer was lost. This is why our evaluation stressed the importance of locking the chafe guard in place.

All five of the products tested provided useful abrasion protection, but when it came to our Best Choice selection, the handsdown winner was the Fjord Chafe-Pro—a commercial product that holds just as much validity for the recreational sailor. In addition to shrugging off the belt sander’s assault, it easily attached to three-strand and braided lines, and the inside strip of Velcro hooks locked it tightly in place. We liked the 2-foot length and felt the heavy-duty chafe protection it offered was just right for those who must set up a boat to ride out a serious blow on a mooring or on a rope anchor rode. We felt the higher price was in keeping with the quality of the product purchased—another case of getting what you pay for.

The Budget Buy award went to the Davis Secure (No. 395), a handy, quick to setup, and streamlined piece of chafe gear. It’s even compact enough to wrap into the first turn around a good-sized cleat and still have enough extension to protect against track chafe.

This round of testing looked at abrasion, construction quality, and design. We have set up a long-term test to see how these products handle UV exposure and atmospheric deposition of chemical pollutants. Stay tuned for the results of the long-term test in a future issue.