SOLDER TENSILE STRENGTH

| MATERIAL | TENSILE STRENGTH | TYPICAL MELTING POINT |

|---|---|---|

| D60/40 SOLDER | 7,000 psi | 361F |

| ALUMINUM BRAZING ROD | 35-47,000 psi | 70-740F |

| ALUMINUM (6061 ANNEALED) | 18,000 psi | 1200F |

| ALUMINUM (6061 T6 TEMPER) | 45,000 psi | 1200F |

Although solder is much weaker than aluminum, brazing filler rods are comparable in strength to common aluminum alloys, depending on the state of temper.

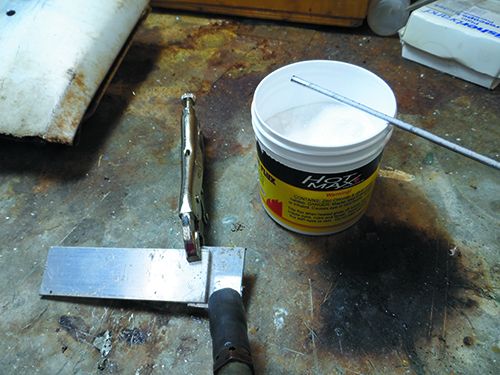

- Moistening the welding rod and dipping it into the flux allowed us better control when making repairs.

- By heating the surface and then touching the flux-coated rod to the surface, we were able to place the solder where it was needed.