Sometimes as a sailor you are learning to run before you can walk or even crawl. If the auto bilge pump isn’t working, maybe it’s faulty wiring or is it clogged? The seawater pump slowly drips and that leads you down a road of a possible impeller repair. And sometimes as a sailor it takes almost sinking to learn one important message “Check your stuffing box!” Wait. Let me rephrase this “LEARN what and where your stuffing box is!”

IT TAKES A VILLAGE TO CARE FOR AN OLD BOAT

It was a beautiful late summer Sunday on the Hudson River. The waters of Haverstraw Bay are home to our 1978 Catalina 30 Rock Steady. She is vintage but has been in my family since the mid 1990’s. When you have a boat this long, you can point out all the sweat equity and projects with pride. From the cabin curtains my mother spent all winter sewing, the blue boot stripe my sister and I tried to paint straight, and the cove stripe my brother effortlessly painted straight—we have all had our part in taking care of her. This all started with my dad, a kid who grew up in Queens, N.Y. and wanted to learn how to sail. It took some time but at 40 years old, with three kids under 10 and living in the northern NJ suburbs, this dream came to fruition. As a self-taught sailor, he learned through books—no YouTube videos then—and by doing. As a family of five we started small: a Hunter 25 with a standard outboard engine and a tiller. After a few years, kids get bigger, and the boat seemed smaller. In 1994, my father upgraded us to the most classic family cruiser produced—the Catalina 30.

As a child I learned the basics of boating and safety and as a young adult I learned how to sail and steer and the rules of the waterway. However, as I grew older and settled into a career and family, I had the time, and perhaps patience, to learn actual boat maintenance and ownership. This was challenging and took many years to gain a good comfort level. Sailing is truly a passion that goes beyond just being on the water with the wind in your hair. You need to understand your vessel or at least identify when something is wrong and know what to do for the safety of you, your passengers and the boat. I thought I had gained strong knowledge about my boat. I knew more about diesel engines and how to maintain them, how seacocks work, the importance of your onboard battery, chainplate leaks, and the famous “Catalina smile.” But that’s the thing about sailing, there is always something new to learn.

At the time of this Sunday sail, I was in my late thirties and had just given birth to my daughter, Emma. Therefore, it was a perfect day to get out of the house and on the water for a sail with my mom and dad. The three of us set out for a few hours in the afternoon as conditions were perfect on the water, weather was clear and wind knots were stable. Although we are primarily recreational sailors, and don’t venture out too far, we have gained our fair share of experiences on the water over the years. We have been through squalls, engine failure, going aground and a rolling furler that got stuck and would not roll up on a very windy day. I learned quickly how big those jib sails really are! As my dad would say after every event on the water, “this builds experience.” Although this is true, at the time no one thinks “I’m glad I am in this storm to learn what to do!”

FLOATING CARPETS

After our idyllic Sunday sail we were feeling refreshed, we lowered the main down, tied it all up and decided to go back to the marina. With the inboard engine started, my dad was at the helm and my mom was keeping watch as we slowly approached the entrance to our marina. For some reason, I decided to look into the cabin as sometimes that loud diesel engine just compels me to give it a quick check. The engine was ok but the carpet in the galley was floating. Huh? That’s odd. Standing at the companionway I could see water, and lots of it, but I could not see where it was coming from. I shouted, “we’re taking on water!” Confusion set in aboard but also a sort of an organized chaos. My mother grabbed extra lifejackets and my dad and I naturally switched positions as I grabbed the helm and he went down to inspect. We were closer to the fuel dock then our slip, so I steered us over starboard facing to get help. I don’t even remember how well or not well I docked the boat, but I threw a line to a dockhand and got tied up.

I told anyone I could that we were taking on water and needed help, ASAP! I don’t know what investigations were going on down below, but I knew we needed a pump as the water was coming in faster than we could pump it out. I was worried about the engine because if the water got too high and we couldn’t stop it or pump it out fast enough, we may cause damage to our Nanni 2.14 diesel engine. After a few minutes, out of nowhere, I spotted that bright yellow powerboat we all know and love— SeaTow. They were coming into the marina around the same time, probably to end their day. As I was signaling them to get help, my dad emerged from below and said “it’s the stuffing box.” Stuffing what? I did not know what that was or why would it cause so much water intake. Did he make that word up, is it an actual box? I don’t remember learning about any sort of “box” on our boat.

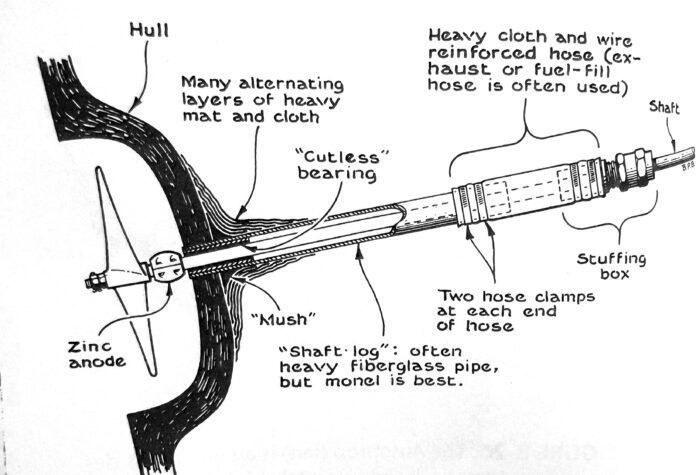

For those with inboard engines, it’s not an actual box but an important fitting on your boat that connects the boat’s propeller shaft to a rubber hose through two nuts, a locking nut and a packing nut. It is also referred to as stuffing glands or packing glands. The packing nut is where the seal is housed. If the fitting cracks, becomes loose, or is not properly sealed, it can sink your boat. Yes, I said sink your boat—seems important to learn.

When my dad went below, he quickly identified the water was coming from under the steps. Our stuffing box is in a compartment under the companionway stairs. A place no one regularly checks or thinks about as it’s mostly stepped on or over and covered by a decorative carpet. Upon opening the compartment, he noticed the stuffing box, which is between the prop shaft and the engine, had a worn seal coupled with improperly tightened nuts. This allowed water to come in as the engine and propeller spun under power. This shaft seal serves a vital function of not letting water into the boat while also allowing the propeller to spin and function. The nuts and clamps should be tightened, the packing shouldn’t be worn, there should be no excessive corrosion to the shaft, and hoses should be in good condition for this mechanical part of your engine to function effectively.

Our fitting had probably been deteriorating long before this sail. We were not doing routine checks, preventative measures were not taken, and parts weren’t replaced. Therefore, after starting the engine, the seal finally had enough and loosened, resulting in a rather large opening allowing water to come in fast and furious. A traditional stuffing box will have minor drips under power, as this is normal for lubrication and release of any trapped air. However, a continuous drip while stationary or under power is an indication that it’s not operating at intended, or you are sinking.

QUICK THINKING AND SEATOW TO THE RESCUE

As in most emergency situations, events happen fast. Everyone mobilized to take action to identify the root cause, get the situation under control and then figure out a long-term solution. SeaTow had an electric pump and some hose plugs for a temporary fix, then we had to get her hauled out for repair. The solution was a new stuffing box. However, instead of replacing with a traditional stuffing box, we had a dripless shaft seal professionally installed, which is an alternative method. The dripless shaft seal is a different mechanical configuration and requires no repacking and supposedly requires less maintenance. However, there are differing opinions on which method to install (tried and true vs. new), but I find there are differing opinions on most everything with sailing—go with your gut or what your budget allows.

So how did we end up nearly sinking? We had done very little maintenance on the stuffing box, connections, fittings and a traditional stuffing box requires repacking or replacing over time depending on usage. This is the most important lesson learned from this experience. As I mentioned before, I was not familiar with this inconspicuous yet very important and functional part of the boat. On our boat, it’s not an “in-your-face” spot as it’s inconvenient. Sailboats can be a bit of puzzle in where fittings, electrical wiring and mechanical fixtures are hiding in plain sight. It’s a good practice to inspect and open these compartments, which is something I now do regularly when the boat is on the hard in the winter.

MAINTENANCE LESSONS LEARNED

As part of my regular maintenance schedule, I now perform a visual check of the stuffing box fittings and connections. I check the condition of the shaft, hoses, clamps and the dripless seal, and ensure they are tight and generally look operational. I also like to run the engine at the dock and watch how it operates under power, as the vibrations and power of the engine can show any potential distress. And since almost sinking is an unforgettable moment, I also purchased a variety pack of emergency boat plugs. Having those onboard in an accessible place is a good idea for any unforeseen water intake. Lastly, start a maintenance log. Once we were at ease that Rock Steady would live on, no one could remember when the stuffing box was installed, maintained, or even looked at.

I will never forget that Sunday sail and how it’s a good reminder that even on an ideal sailing day in perfect conditions anything can go wrong. Knowing your boat, staying calm and organized are key takeaways. Also, I hope this story not only informs you to always check every fitting, connection, clamp on your boat each season but to also have a variety pack of hose plugs (you never know!). I didn’t know what a stuffing box was or its importance, but hey, that’s the life of a sailor, always learning something new!

Well that sounds like a harrowing experience. Good old dad to the rescue. 🙂 We sail the same waters. Always comforting seeing many SeaTow and TowBoat US vessels in the area.

It’s my understanding that with a dripless shaft seal, you don’t have a traditional stuffing box anymore. Seal and connections still need to be checked, but there’s no flax, or need to burp the seal for proper lubrication with a dripless. At least that’s what they told me, as I have a Tides Marine dripless that recently needed replacing.

Thanks Brian for your comments! Nice to see you also sail the same waters too. I am also under the same impression with the dripless. I don’t think anything is truly maintenance free but just a different configuration that requires differing types of checks. So far ours has been okay, but then again you never know 😀. Sail on!