Two things, as they say, are certain in life: death and taxes. Perhaps a third would be that fuel cost will inevitably keep rising. So, it benefits your boat and your wallet to maintain both your engine and fuel quality. Like many have heard me say, “maintenance costs less than repairs, in both time and money.”

In essence, your spring engine start up begins in the fall with proper, in tank, fuel care. Topping up with new fuel and adding proper fuel stabilizer additives will minimize condensation and keep your fuel quality and fuel system in good condition. In the case of diesel fuel, adding diesel fuel biocide will also prevent fungus growth, which will also protect the fuel filters. My go-to products are Biobor JF and K-100 MD.

If you prepare the fuel properly in the fall, when spring arrives, fuel should not be an issue or concern.

FIRST STEPS FOR SPRING

Assuming batteries have been properly stored and charge levels maintained during the winter and there’s no visual damage after a physical inspection, your next step is to clean connections and apply a thin coat of lithium grease to each battery terminal, which will help keep corrosion at bay. Of course, depending on if you use your boat in a salt or fresh water environment also dictates what other preventative measures you’ll need to follow.

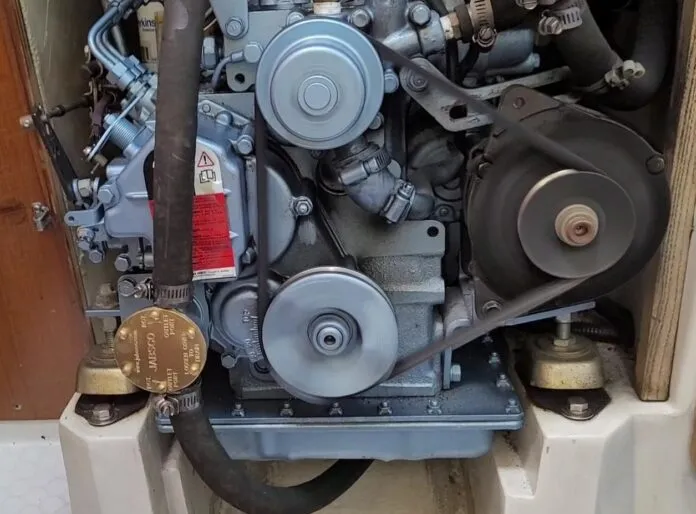

Do a visual check and clean of the engine, looking for any leaks, worn or damaged wires and connections. If you’re running a gas engine, inspect and clean your spark plugs, checking for cracks and proper gap. Replace them as needed. Inspect and service the air filter element as needed. Also, check the engine mounts for wear.

Antifreeze: Up here in the great white north, where boats are taken out for storage, winterizing also means running and keeping antifreeze throughout the cooling system. I do this by running my diesel engine on land while feeding antifreeze through the water intake thru hull under the boat. I’ll do this until antifreeze spews out of the exhaust port, then shut the engine off.

Normally, boats with enclosed cooling systems already run with an antifreeze mixture. So flushing may not be a yearly requirement. But checking the quality of the antifreeze is! An inexpensive antifreeze tester is well worth keeping onboard. It will indicate up to what temperature range the antifreeze is still good for. Do this in the fall before winter sets in.

Come spring, you now need to flush out the antifreeze with fresh water while the boat is still on land so you can capture the antifreeze in a bucket for proper disposal. I use a 5-gallon bucket filled with fresh water and a hose going from the bottom of the bucket to the water intake thru hull.

I then put a hose from the exhaust port to another bucket or recipient, so that once I start the engine, the used antifreeze will be directed into that bucket. Once clean water comes out of the exhaust port, I move the bucket away and keep running the engine for about five minutes at about 1200 RPM to get a good water flow going. I then shut off the engine.

Afterwards, I transfer the used antifreeze to an empty windshield-washer fluid container and bring that to a proper disposal facility such as most automotive service retailers. Look for the disposal bins, which are often near the car service center. This is also where old oil and oil filters should be disposed of as well.

To protect our waterways, please do not flush out the antifreeze once you have launched the boat!

My boat also has a backup antifreeze system with an onboard 1-liter reservoir. Using the antifreeze tool, I also check the quality of that fluid but do replace it every three years.

ENGINE FLUSH

Now with the engine off, I complete the process by checking the engine oil level after about 20 minutes to make sure it has all flowed down to the oil reservoir in order to get a proper read. Since I always do my oil and filter change in the fall as part of my winterizing process, the oil level should be good. I also check the oil level in the transmission, although this should always be checked once in the water where you can run the engine and transmission under load. Never run the transmission in gear while on land.

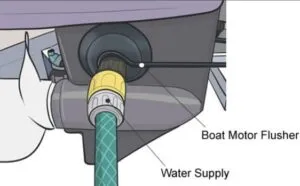

Of course, the above relates to inboard engines, but the same care should be given to any outboard engine. Make sure to give them a good fresh water flush using a hose adapter connected to the water intake ports on the foot.

Finally, clean and grease any areas such as cables, joints and connections to ensure proper operation.

Barring any issues found along the way, you should now be ready to launch with the confidence that at least the all-important propulsion system is in proper order and should get you back safe and sound every time.

Terrific article

Curious why you would be using antifreeze that requires proper disposal, e.g. ethylene glycol. Why not simply use the propylene glycol based pink antifreeze that is harmless to both animals and environment?