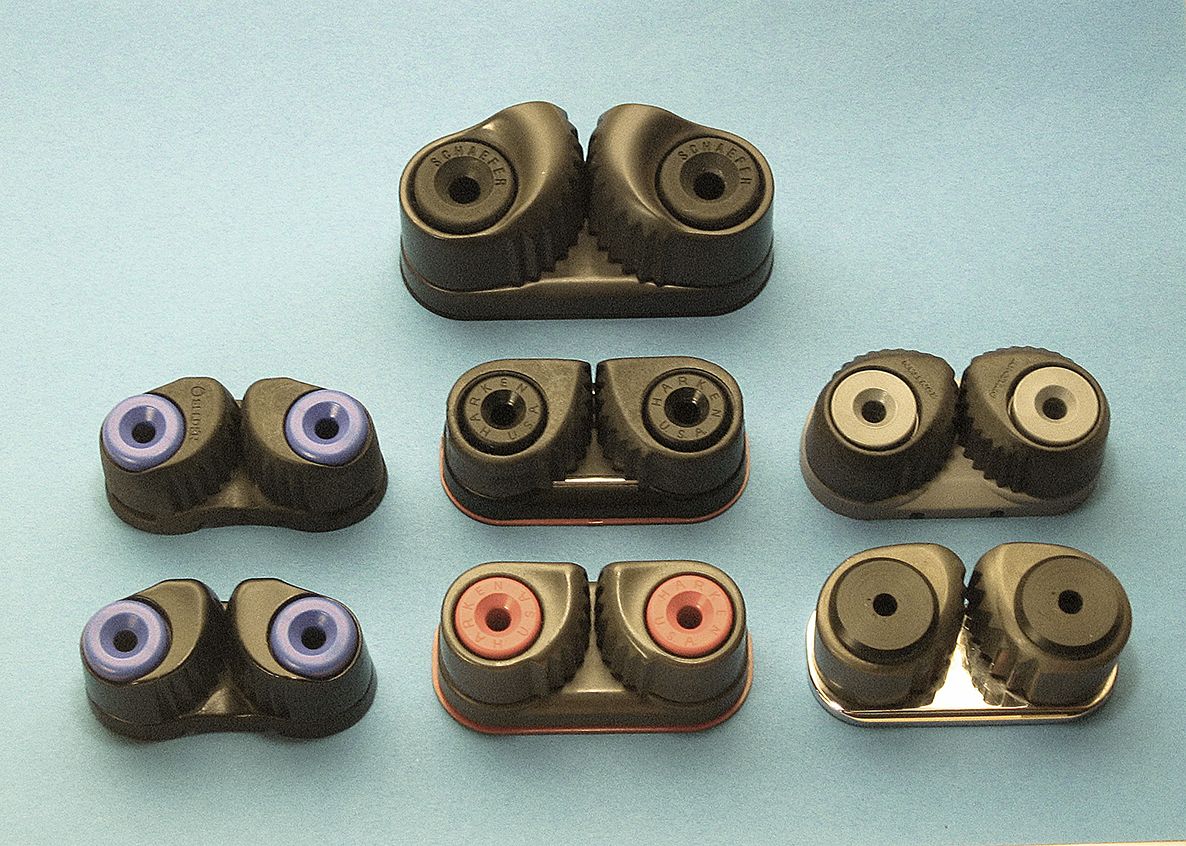

Practical Sailor has tested cam cleats several times during the past 50 years. Our first head-to-head cam-cleat test was back in the late 70s. Some of these devices have come a long way since then; others haven’t.

Looks aren’t a good criterion for judging cleats. Just because it looks modern doesn’t mean that it’s better than one that looks antiquated. Good cam cleats engage and release line easily, hold at high loads, and most importantly, are non-destructive to line. Bad cam cleats break easily, operate stiffly, allow the line to slip or jump out at low loads, and tear your line to shreds.

Cam cleats, the forerunners of jammers and rope clutches, are to small boats what jammers (also called sheet stoppers) are to large boats. Unlike rope clutches, jammers and cam cleats can’t be released under heavy load. You have to pull, jerk, or winch on the tail to relieve the load before the line can be released from its grips.

Although once a low-ticket item costing less than $20, cam cleat prices have soared in recent years, and even the least expensive cleats can add up for a small boat owner who has 4-6 cam cleats aboard his 22-footer. The cost can become especially significant if a poorly chosen cam cleat chews through several halyards and sheets. Line ain’t cheap.

Application

The most common use of cam cleats is to cleat sheets. Any jib sheet or mainsheet that you can trim without the use of a winch should be held by a cam cleat. Because cam cleats are rarely overloaded and sails are constantly adjusted, ease of cleating and uncleating is far more important a criterion for choosing a cleat than load carrying capacity. Cam cleats are also used for halyards, reef lines, spinnaker pole controls, cunninghams, outhauls, etc.

Racing sailors, as well as our tech editor Drew Frye, often prefer a cam cleat to the clam cleat at the top of a self-tailing winch because the cam cleats are quicker to cleat and to release. Frye detailed his use of cam cleats and low-friction rings to simplify trimming aboard his Corsair F-24 trimaran in the March 2023 report, “Better Winch Grip.”

The controlling factor for any application is the load on the line. A cam cleat is less than half the price of a rope clutch, but even a good cam cleat will only hold half the load of a clutch. Also, as already mentioned, when subjected to heavy loads, most cam cleats are difficult to release without first relieving some of the tension with a winch.

In general, cam cleats should be used on halyards and reefs on boats under 26-feet, pole lifts on boats up to 30 feet, and pole foreguys, cunninghams, and outhauls on boats to up to 40 feet.

Cam cleats are more difficult than jammers to arrange in a “bank” so that several are served by the same cabintop winch. Most makers of jammers and rope clutches offer double- or triple-stopper configurations, which can give several lines a fair lead to a winch.

Cam cleats, with their wide athwartships profile, are another story. To lead several lines to a winch, cam cleats must either be staggered and overlapped fore and aft, or have fairleads between the cleat and the winch. It should be noted that any earn cleat led to a winch must be raised to the height of the winch with a pad, or it will need a fairlead between itself and the winch.

For halyards and other sail control lines that you may want to trim in a hurry (say, for racing), a fairlead mounted behind the cleat will allow you to trim the line from anywhere in the cockpit and have it “self cleat.” When mounting fairleads behind a cam cleat, be sure to leave enough space in front of the fairlead to be able to grasp a handful of line when it comes time to uncleat.

Design

Most cam cleats can be disassembled for cleaning or inspection. A well-designed cam cleat can only be taken apart by careful prying with a screwdriver. Some cleats, however, will fall apart if you drop them. Others spring apart. Cam cleats are quite similar when it comes to uncleating. In our experience all cam cleats are very difficult to release under great strain.

Cam cleats are not similar with respect to ease of cleating. With an inferior cam cleat, you must trim the line through the cleat to make the “jaws” open. With a good cam cleat, the jaws will open with a simple downward push on the line. The more downward pressure you can exert, the more easily the cleat will open. The cleat should be mounted to enable you to pull down as you trim. If you can’t mount it on the edge of a deck, cabinhouse or coaming, you may want to mount it on a pad. Pads which are angled upward toward the operator make them easier to cleat, but be careful not to angle the pad so much that the line jumps out of the cleat.

Cam cleats with teeth that flare outward and back are usually easier to cleat with straight downward pressure. However, this feature does not help the cleat to open as you draw the line through it; in fact, it can inhibit cleating in this manner. Thin line is easier to cleat than thick line. Cleats with more space between the cams, specially designed for thicker line, are easier to cleat. Several of our favorite cam cleats in our previous Practical Sailor test of cam cleats had ball bearings for frictionless cleating. Several also mounted their cams on a thick base plate, so the cleat is pre-padded to make cleating easier.

Some cam cleats have very sharp teeth and voracious appetites. They love to munch on line. Years ago, after testing more than a dozen different cam cleats, our testers couldn’t understand how some of them managed to stay on the market. They jokingly speculated that perhaps endorsements from the rope manufacturers were keeping them in business. The late Jeremy McGeary, yacht designer and longtime Practical Sailor Tester, dug into the topic of line damage in his extensive cam cleat test.

Sailors should also be aware of cam cleats that are also skin eaters. Cleats with sharply pointed, flared teeth can be very uncomfortable to sit on. Also be wary of cleats that fasten with round head bolts instead of countersunk flat head bolts. Any burr in the screwdriver slot will be exposed and will cut like a knife.

Construction and Holding Power

All cam cleats are designed for use with a certain range of line diameter. Some manufacturers list both ends of the diameter spectrum. The Harken Cam-matic cleat has a particularly wide range, from 1/8″ to 1/2″ line; the Schaefer Fast Entry cam cleat has a narrower range, from 1/8″ to 1/4″ line.

Other manufacturers list only the largest diameter that the cleat will accept. For example, the manufacturer may say that a cleat will accept “up to 5/8 line,” but this does not mean that it will hold any diameter up to 5/8″. Typically, they will not hold any line smaller than 1/4″.

Most cam cleats hold thicker line better, although they may work easier (cleating and uncleating) with thinner line. Therefore, it often pays to get a slightly oversize cleat for a sheet, even though a sheet is lightly loaded. This is because a sheet is eased and trimmed constantly, so ease of working is more important than holding power.

Strength and Durability

Ultimate strength is important; during our original test cam cleat durability back in the 80s, we broke four of the 13 cam cleats we tested, most at surprisingly low loads. (Our most recent test did not see failures, but the focus of that test was on line wear.) As a line is tensioned, the cams of a cleat compress it to a smaller and smaller diameter. Eventually, either the line will slip, jump out of the cleat, or the cams will hit their “stops.” Stops are what keep a cam cleat from rotating 360 degrees. On a quality cam cleat, the stops are cast into the base plate or the cam. However, most cleats have stops that are cut from the base and bent upwards to hold the cam. If the base is too thin, as many are, this type of stop is easily bent or broken.

Plastic cams can also cause problems. To be strong, a plastic cam must either be glass-reinforced and/or have steel inserts where the cam hits its stop. We’ve had cam cleats break when their plastic cams deformed as they were forced against the stops. The durability of a cam cleat’s springs is largely dependent on the quality of the steel used to make the spring. It has been our experience, however, that band springs are generally more durable than wire springs.

To see what cam cleats fared best in our last big head-to-head test, check out the article and three different tables comparing cam cleats in the Practical Sailor Cam Cleat Report, “Eight Sailboat Cam Cleats Tested on Doomsday Device.” For a look at a wide range sail control hardware, including our tests of boom vangs, travelers, and snatch blocks, check out our three-volume ebook, “A Look at Sails.”

Thank you got the info ,will be buying a sailboat in the near future and any tools are welcome.

Steve Rez

I believe part of the article is missing: the results.

The links within the blog post go to the testing reports. There are links to the tables of results at the bottom of each test report. The print PDF versions in our archives have more images. The issue of the print PDF is the month after the date the original date of publication online. If you need help finding a test report. Contact [email protected].

Here’s a simple cam cleat release. Place a fairlead close to the cleat, slide a filled PVC slug under the line between the two. Make the slug small enough not to free the line under normal strain but big enough to lift the line out of the cleat before something breaks.

I have an 8m trimaran with pivoting board and rudder. The 6mm DB downhauls have lifted out every time I’ve hit something at speed.