For more than four decades, Practical Sailor has been testing bottom paints, although for the first few years, the topic really didn’t draw much attention. This was back in the day of Tributyl tin (TBT), a highly effective antifouling agent that easily delivered three years of protection in most saltwater environments. While expensive, paint prices weren’t so outrageous back in those days, and yards didn’t mind if the owners applied the paint themselves. By the early aughts, TBT had fallen out of favor worldwide because it was clearly harmful for the marine environment. Given the amount of abuse that we’ve heaped upon our oceans, and the influence of the global shipping giants over environmental policies that impact their bottom line, the fact that all parties eventually agreed to a total ban on the use of TBT illustrates the severity of the potential harm.

The post-TBT era put us back to the early days of antifouling, when copper was king. Copper sheeting, once the preferred protection during the age of sail, remains popular in some corners of the wooden boat world. But for the rest of us with FRP boats, copper-laced paint is the prescription.

Over the years, the means of releasing (also called leaching) copper biocide have improved, and a variety of “boosting” agents have come and gone—the most recent being the pesticide Irgarol. Some of these boosters proved not to be worth the extra cost, others—like TBT—proved to have unintended negative impacts, especially in more fragile environments like the lakes in Europe.

Because of the global nature of the antifouling market, bottom paint formulas are more heavily influenced by European regulations than most other product that we buy at our local chandleries. Although consumers in the more loosely regulated U.S. market might continue to see a product that has been banned in Europe for a year or two after the ban, eventually the paintmakers (many of them with headquarters in Europe and with manufacturing plants abroad) typically eliminated the line altogether.

In recent years, except for the growing interest in hard, super slipper “nano-particle” ceramic coatings (see adjacent story), product development seems to be stuck in a predictable cycle. A few standby, high-copper-content products continue to deliver good performance and dominate the market, while various additives that claim to deliver enhanced performance come and go as cost or regulatory policy makes them unprofitable.

Being creatures of habit, our testers at Practical Sailor also fell into a pattern, repetitive testing that focused primarily on saltwater performance. We’ve conducted tests in the Great Lakes in recent years, but until last year, we’ve never focused exclusively on a brackish water environment with reduced salinity—even though many popular mooring fields and marinas are located in brackish water environments. (It is also worth noting that one of the perennial saltwater champs in our testing, Interlux Micron 66, is rendered impotent in brackish water). And so, better late than never, we present the second of at least three reports on bottom paint performance in the brackish backwaters of Chesapeake Bay, one of the most popular sailing estuaries in America.

Earlier last year, we published an introduction to the test, with a detailed discussion of copper release rates and how regulatory agencies that were once cracking down on copper paints (namely in California and Washington State), are now backtracking after confronting a number of serious hurdles—the most distressing being that many of the so-called “safer” antifouling agents introduced to replace copper have turned out to have their own, often more severe, negative consequences on the environment.

CHESAPEAKE BAY TEST RESULTS

To be completely fair, predicting long-term performance after just one year of immersion is a bit of a gamble. In nearly every past test we’ve done over the years—mostly in Florida and in New England—we don’t see any obvious failures until the 18-month mark, when most of the less effective paints, and a few of the top performers, begin to lose their potency against hard growth.

At the 12-month mark, which is where we are now, most contemporary antifouling paints will be able to keep hard growth at bay (or at least they should, considering the price of a “low-budget” bottom paint these days). The only failures at the 12-month mark are usually freshwater paints (when tested in saltwater), copper-free paints with “eco-friendly” formulas, or low-copper budget paints (including sloughing paints) that are designed to last only one season.

The current crop of paints appear to be falling into the same pattern as previous 12-month tests. Very few of our test panels are beginning to succumb to hard growth, and the majority of these are either copper-free formulas, or are formulas that are designed to protect the hull for just one season (12 months or less). The single-season paint is most popular in higher latitude climates where boats are hauled out each winter, and the repainting process is scheduled into the annual pre-launch routine in the spring.

PAINT TYPE AND HULL CLEANING

As we’ve discussed in past reports, the difference between a single-season paint and a multi-season paint isn’t just a function of the amount of copper in the paint. Just as important to a paint’s effectiveness is the rate at which the biocides are released. More expensive, multi-season paints will have rosins and binding agents that release the biocide at a controlled rate.

Some of the lesser expensive paints, especially the traditional “soft” sloughing paints rely on physical forces, namely the friction of water passing over the hull (or regular cleaning), to expose more biocide that will combat growth. These sloughing paints should not be confused with the generally more expensive ablative copolymers, which have a controlled release rate, and are also frequently referred to as “soft” paints.

As far as hull cleaning goes, this is one of the most commonly overlooked factors that can impact the life of your bottom paint. We’ve explored hull-cleaning in depth in previous reports, but it is worth a quick review here, especially in light of the nature of this test—a brackish environment with water that is generally warm enough to dive in during the sailing season.

As a rule of thumb, you should always use the least aggressive means to clean your hull. If you have a diving service that cleans your hull for you, grill them about their methods and equipment. If they are using anything more abrasive than a square of soft carpet for the first few early-season cleanings, you might want to find another service, or school them on your preference. We actually use a t-shirt for a soft, wipe-down during those first few months when there is only light growth. Depending on your home waters and how you use your boat, you might go several months before requiring any cleaning at all.

You can, of course, be more aggressive with some of the harder paints, but no matter what type of paint you have, if you are stirring up a cloud of pigment you can bet that there’s some still potent biocide being scrubbed off as well. If you plan to boat through the winter in a colder climate, you should see our report on the Davis Scrubbis, which has proved a great help in keeping our Chesapeake Bay boat clean through the winter.

TOTAL BOAT

Over the past 20 years, what was once a supply house to the Rhode Island boat building community has mushroomed into one of the most comprehensively stocked supply sources for the North American DIY boater. In addition to the broad range of major brand products that they sell retail, Jamestown Distributors launched several years ago its own line of products, called Total Boat. One of the company’s hallmarks is customer support through its tech line, reinforced by a large library of DIY videos that do a good job of explaining simple projects. Just keep in mind that videos almost always makes jobs seem easier and quicker than they are in real life due to the compressed time frame.

Although the Total Boat single-season Select paint provided less-than-stellar protection in the Chesapeake, Krypton and Spartan were solid performers in this early round of testing. For the first eight months, the Total Boat Krypton was clearly in the lead among the Jamestown Distributor Paints, staying bright green right through the summer in our panel testing. This paint is also compatible with aluminum hulls and outdrives.

PETTIT

Testers were curious about the performance of the Pettit’s new Odyssey line, which has been developed to fill the gap in slime-resistant paints, since some of the active biocides used in these paints were phased out. Having built a good reputation for addressing the needs of racing sailors and performance cruisers, Pettit has spent a lot of time working to improve resistance to slime during the early months of immersion, leaving the bottom as smooth as it was on launch day.

So far, the Odyssey paints are providing the same dependable performance as some of Pettit’s SR paints from past tests that had the pesticide Irgarol in them.

Any time a new line of bottom paint is introduced, the hype often exceeds the reality, and in terms of active ingredients, there’s nothing particularly “revolutionary” about the Odyssey line. Nevertheless, the paint is definitely holding up well, and based on early field reports from Florida boaters, it looks to be a reliable—if not expensive—bet for long-term protection.

The Trinidad line is also living up to its good reputation from past tests. At one year, the three high-copper hard paints bearing the Trinidad label are doing well. In addition to the panels and test section on the multihull in the Cheseapeake, we have an around-the-buoy race boat in Southwest Florida going on its second year in the water. The boat has been scrubbed bi-monthly and is only now beginning to see small barnacles near the waterline, which are easily popped off with a plastic scraper.

Although it is a little early to tell, based on past performance and what we are hearing from the early “beta” testers out sailing with Odyssey paints, we expect both the Odyssey and the Trinidad paints to deliver good 2-year results in most environments.

E PAINT

Epaint has long been a top performer in the eco-friendly category, virtually locking down first place in the no-copper, long-term protection category year after year in our Florida testing. Nevertheless, we’ve had reports of mixed results in other locations, usually in areas with unusually heavy fouling but not a lot of sunlight. The paints are photo-active, meaning that sunlight helps activate the chemical process that helps protect the hull from growth. Although the paint has performed well at higher latitudes (including entire fleets in Long Island Sound), we’ve consistently seen the best results at our Florida test site.

The other consideration with Epaint is the prep work involved on hulls previously painted with another paint. Because of their formulation, Epaint’s might not adhere with your existing paint, so it is important to consult the manufacturer if you have a previously painted hull. On the other hand, if you are planning to strip off all your old paint and apply a barrier coat, this would be a good time to look at Epaint and some of it’s copper-free formulas.

Anticipating a challenging environment for the Epaints, we were especially curious about how they would perform on an actual boat hull, which would create some friction underway to aid with self-cleaning. In order to take full advantage of their photo-active properties, we applied the paints to two of the amas on our test boat, an F-24 trimaran, where they would receive sufficient exposure to the sun.

The photo-active nature of the paint was clearly apparent at the one-year mark. While other paints generally show more growth near the waterline where algae and soft growth benefit from the unfiltered sunlight, the Epaints actually showed less soft growth near the waterline, and more soft growth along the bottom of the hull, where even some hard growth was beginning to take hold. Any hard growth on the copper-based paints on our test hull was negligible.

On the good side, however, Epaint’s exceptionally hard paints were very easy to clean. For example, the barnacles on the section of the test hull painted with EP 2000—a perennial winner in the eco-friendly category—were easily dislodged with barely any pressure at all, as if the barnacles had not yet gained a foothold. Although the Epaints are technically not a “slick paint,” a paint that relies solely on its super-smooth surface to resist growth, the nature of the biocide and their surface hardness will make them much easier to clean than a conventional copper hull that has lost its punch.

To test the ease of cleaning on the test boat, we postponed boat scrubbing until 14 months after launch. Testers were impressed to see that the amas painted with EP ZO and Ecominder came clean with minimal effort using only the Davis Scrubbis. The barnacles slid off without scraping. At this point, the more conventional copper paints had very, very few barnacles, but a plastic scraper would be required to pop them off.

INTERLUX

The primary brand falling under the Akzo Nobel parent company, Interlux is known outside the U.S. as International Paint. The company’s global reach gives it an advantage for cruisers planning to voyage abroad, since International paints are available in almost every popular haulout location that a cruiser will visit. This makes it easier to find a compatible paint for your existing paint, the first criteria to establish when selecting a new bottom paint. If you can’t find a compatible paint, you generally have to do more sanding, or add a tie-coat primer, or, in some cases, remove all of the previous coating. The company, like all of the paints in this test, also provides responsive technical support to its customers.

One of Interlux’s most popular paints, Micron CSC is a perennial favorite in the Chesapeake Bay. This is an expensive high-copper ablative copolymer meant to provide multi-year protection. Our relatively clean panels show why it is so popular. According to independent testing done to determine compliance with proposed environmental regulations on the west coast, this paint also has one of the higher copper leach rates among its peers. Among the other Interlux varieties Micron Navigator looks good, as does Ultra-Kote (a hard paint).

SEAHAWK

AkzoNobel, the parent company of Interlux, picked up Seahawk and Bluewater Paints a few years ago, but so far they have kept the product lines, manufacturing, and support separate. All of the Seahawk test paints performed well, including Smart Solution, which is copper-free. Seakhawk is unique in recommending that you can mix Biocop TF with their other copper-based paints for improved antifouling. The Biocop panel, like most of the top-tier paints, shrugged off all but a thin coating of slime in the first 12 months.

WEST MARINE PCA GOLD, 2010

This paint was included as a baseline comparison panel. We wanted to see how an Irgarol-boosted paint formulated before the new copper leaching restrictions took hold and before Irgarol was phased out would match up against the current crop of paints. We’ve used it several seasons in the Chesapeake and knew what to expect. At the one-year mark it was doing well, exactly as we had observed in prior panel testing in this location, and very similar to the best paints in this round. (The West Marine PCA Gold formula tested was made by Pettit and was essentially identical to Pettit SR 40. Its closest current peer is Pettit Odyssey HD.)

CONCLUSION

After initially scapegoating copper bottom paint on recreational boats for harbor water quality issues, and hearing a lot of “copper will be banned” talk, it seems a more sensible limit on leaching rate is being accepted and the new paints are being tweaked to meet it. We were pleased to see many of the paints performing right up there with our 2010 West Marine PCA Gold reference paint. In fact, we’re not really expecting a general drop in performance, primarily because the better two-year paints already met the recommended leaching limit.

As for copper-free paints suitable for outdrives or aluminum hulls, Total Boat Krypton is worth watching; the boat section was very clean and the stationary panel was good. Micron Navigator looks to be another good option in this category.

As we expected, the test sections on our test hull looked better than stationary, panels, particularly with regard to soft growth. No doubt our frequent sailing (every two weeks on average) and relatively high speeds (most days we see over 10 knots at least part of the trip) contribute by exposing fresh biocide and by scrubbing off slime. Go sailing more often. It’s good antifouling maintenance!

We need to re-think our no-scrub protocol for the on-boat test areas. The E-paint samples on the amas are a relatively slippery hard paint, which can withstand scrubbing and proved easy to clean, and that would seem a good compromise with this copper-free paint. Going forward we’ll be using the Scrubis at regular intervals, and going for an occasional scrubbing swim once the water gets warm. For now, we’ll leave the hard paints on stationary panels alone. However, since just about every boat owner begins scrubbing their hull by the two-year mark, we may include ease of cleaning into the next evaluation. Soft paints, on the other hand, will last longer with only minimal cleaning (see “Bottom Paint Care,” PS April 2018).

We won’t know much about long-term anti-fouling for another year. The winter cold should knock off much of the soft growth, but we expect some aggressive growth starting in June, and will try to minimize boat cleaning until our next evaluation in October 2023. Prior experience suggests that paints with higher copper loads, including Pettit Odyssey 60 and the Trinidad line, Micron Ultra-Kote, and Seahawk Bio-Cop have the best chance of hanging in there for the full 2 years. At that point we will haul the boat for paint, but the test panels will remain in the water until the last panel fails, however long that takes.

CONTACTS

EPAINT

800/258-5998, www.epaint.com

INTERLUX YACHT FINISHES

800/468-7589, www.yachtpaint.com

KOP-COAT (PETTIT)

800/221-4466, www.pettitpaint.com

SEA HAWK

800/528-0997, www.seahawkpaints.com

WEST MARINE

800/262-8464, www.westmarine.com

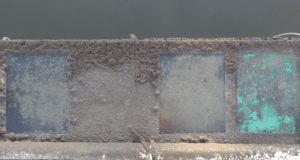

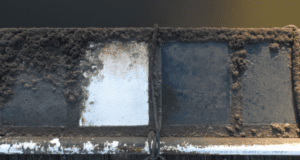

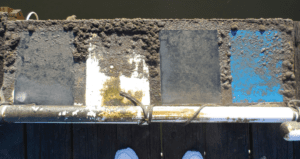

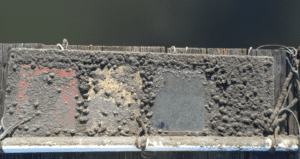

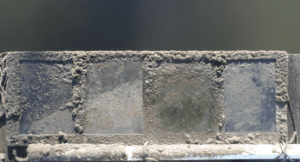

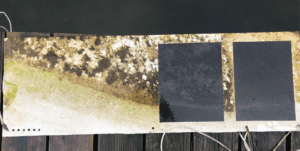

After one year of immersion, the most aggressive growth were soft marine-invertebrates and algae creeping in from the edges. All panels had at least a thin layer of slime. Photos don’t necessarily tell the whole story. When evaluating panel performance, testers focus on the center of the panel, as marine life can gain a foothold along the unprotected edge and migrate inward. Darker colors can also camouflage light fouling, making these paints appear more effective. Hard growth has not yet overtaken any panels.

1. Micron CSC, Odyssey Triton, Trinidad Pro, Krypton.

2. Ecominder, EPaint ZO, Odyssey 60, Micron Aqua

3. Trinidad HD, EP-21, Trinidad 75, Micron CF.

4. Total Boat Spartan, Odyssey HD, EP 2000, Micron WA

5. Total Boat JD Select, Micron Navigator, EP 2000, no coating.

6. Seahawk Cukote, Seahawk ColorKote, Seahawk Smart, Interlux Ultra-Kote

7. No coating, no coating, West Marine PCA Gold (2010

formula with Irgarol), SH Biocop

VALUE GUIDE: ANTIFOULING BIOCIDES, LEACH RATES, AND PRICE

| BRAND | TYPE | SOLVENT | COPPER | ZINC | “BOOSTER” BIOCIDES | LEACH RATE (μg/cm2)** | PRICE / GAL. † |

|---|---|---|---|---|---|---|---|

| Total Boat | |||||||

| Krypton | Ablative | Solvent | None | About 7% | Tralopyril, zinc pyrithione | 199 | |

| JD Select | Hard (1 season) | Water borne | 0.25 | None | None | Not tested or reported. | 134 |

| Spartan | Hard | Solvent | 0.38 | None | None | Not tested or reported. | 189 |

| Pettit | |||||||

| Odyssey 60 | Ablative | Solvent | 0.6 | ~ 7% | None | Not tested or reported. | 264 |

| Odyssey HD | Ablative | Solvent | ~ 40% | ~ 7% | None | Not tested or reported. | 232 |

| Odyssey Triton | Ablative | Solvent | ~ 40% | ~ 7% | Econea, copper thiocyanate, | Not tested or reported. | 400 |

| Trinidad 75 | Hard | Solvent | 0.6 | None | None | Not tested or reported. | 268 |

| Trinidad Pro | Hard | Solvent | 0.65 | None | Irgarol* | 320 | |

| Trinidad HD | Hard | Solvent | 0.6 | None | Irgarol* | 230 | |

| Epaint | |||||||

| EP 2000 | Hard | Water borne | 0 | 0.05 | Zinc omadine | 237 | |

| E Paint ZO | Hard | Solvent | 0 | 0.05 | Zinc omadine | 237 | |

| Ecominder | Hard | Water | 0 | 0.4 | Zinc pyrithione | 164 | |

| EP-21 | Ablative (1 season) | Water | 0 | 0.5 | None | 137 | |

| Interlux | |||||||

| Micron CSC | Ablative | Solvent | 0.37 | 10-25 % | None | 250 | |

| Micron WA *** | Ablative | Water | 0.48 | 10-25 % | None | Not tested or reported. | 240 |

| Micron CF | Ablative | Solvent | 0 | 10-25 % | None | 290 | |

| Micron Navigator *** | Ablative | Water | 0 | 2-10% | Zinc pyrithione | 275 | |

| Ultra-Kote | Hard | Solvent | 0.57 | None | None | 260 | |

| Fiberglass Bottomkote Aqua *** | Hard | Water | 0.46 | None | None | Not tested or reported. | 240 |

| West Marine | |||||||

| PCA Gold | Ablative | Solvent | 0.4 | None | Irgarol* | 229 | |

| Sea Hawk | |||||||

| Smart Solution | Ablative | Solvent | 0 | None | None | Not tested or reported. | 195 |

| Colorkote *** | Ablative | Solvent | 0 | 0.1 | Econea, copper thiocyanate, zinc pyrithione | Not tested or reported. | 245 |

| Cukote | Ablative | Solvent | 0.47 | 0.1 | None | 240 | |

| Biocop TF | Ablative | Solvent | 0.38 | 0.1 | Zinc pyrithione | Not tested or reported. | 280 |

| *Irgarol is no longer used. **Leach rates per 2015 State of California Water Board study, expressed in micrograms per centimeter squared (μg/cm2). Leach rates may be different in 2022 paints. ***Not approved for use in California (Colorkote approval is pending). †Prices vary by source. |

VALUE GUIDE: ANTIFOULING COLORS, DRY TIMES, BRACKISH WATER RATING AT 12 MONTHS

| BRAND | OVERCOAT* | LAUNCH* | COLORS AVAILABLE | PANEL RATING | FIELD TEST RATING |

|---|---|---|---|---|---|

| Total Boat | |||||

| Krypton | 1-4 hrs. | 2-8 hrs. | Black, white, blue, red, and green | Very good | Excellent |

| JD Select | 1.5-6 hrs. | Overnight | Black, blue, red, and green | Good | - |

| Spartan | 1.5-6 hrs. | 6-16 hrs. | Black, blue, red, and green | Very good | - |

| Pettit | |||||

| Odyssey 60 | 1-6 hrs. | 4-16 hrs. | Black, blue, red, and green | Excellent | - |

| Odyssey HD | 1-6 hrs. | 4-16 hrs. | Black, blue, dark blue, red, and green | Excellent | - |

| Odyssey Triton | 1-6 hrs. | 4-16 hrs. | Black, white, blue, red, and green | Good | Very Good |

| Trinidad 75 | 1-6 hrs. | 4-16 hrs. | Black, blue, and red | Excellent | - |

| Trinidad Pro | 1-6 hrs. | 4-16 hrs. | Black, blue, red, and green | Excellent | Excellent |

| Trinidad HD | 1-6 hrs. | 4-16 hrs. | Black, blue, red, and green | Very good | - |

| Epaint | |||||

| EP 2000 | 5-16 hrs. | 1-2 days | Black, white, yellow, safety orange, gray, and blue | Good | - |

| E Paint ZO | 3-8 hrs. | Overnight | Black, white, gray, green, and blue | Excellent | Very Good |

| Ecominder | 5-16 hrs. | Overnight | Black, white, yellow, safety orange, gray, green, blue, and dark blue | Fair | Good |

| EP-21 | 5-16 hrs. | Overnight | Black, white, yellow, safety orange, gray, green, blue, and dark blue | Very good | - |

| Interlux | |||||

| Micron CSC | 1-4 hrs | 16 hrs. | Black, red, green, shark white, and blue | Excellent | Very good |

| Micron WA | 2-24 hrs | 6-48 hrs. | Black, red, green, and blue | Very Good | - |

| Micron CF | 2-12 hrs | 4-18 hrs. | Black, white, red, green, blue | Good | - |

| Micron Navigator | 1-6 hrs | 1-48 hrs. | Black, red, green, and blue | Excellent | - |

| Ultra-Kote | 2-6 hrs | 6-12 hrs. | Black, red, green, and blue (gallons only) | Excellent | - |

| Fiberglass Bottomkote Aqua | 2-24 hrs | 6-48 hrs. | Black, shell white, red, green, and blue | Very Good | - |

| West Marine | |||||

| PCA Gold | 1-6 hrs | 4-16 hrs. | Black, blue, dark blue, red, and Green | Excellent | - |

| Sea Hawk | |||||

| Smart Solution | 2-6 hrs | 12 hrs. | Black, white, red, green, light blue, dark blue, & light gray | Very good | - |

| Colorkote | 5 hrs | 12 hrs. | Black, white, yellow, red, green and blue, mixable to create 46,656 colors | Excellent | - |

| Cu Kote | 2 hrs | 12 hrs. | Black, white, red, green, teal, blue, dark blue | Very good | - |

| Biocop TF | 2 hrs | 12 hrs. | Black, white, red, green, light blue, blue, teal, dark blue, gray | Excellent | - |

| *Overcoat & launch times vary by temperature and humidity. Follow maker’s guidelines. |

If “copper is king”, why haven’t you included Coppercoat in your study? I’ve found it worked well for me in brackish warm waters (Puerto Vallarta, Mexico).

Have you tested or heard anything about SLIPS Dolphin Bottom Paint by AST? Seems like it accomplishes the same thing as RENOLIT Dolphin S but without having the downsides of a single sheet of material. Curious how it actually does as I’m excited to never have to put another coat of ablative on my boat again.