The physical installation of a water heater may seem pretty straightforward, but the devil is indeed in the details. It starts prior to purchase with a search for adequate space thats relatively near the engine and vertically as low as possible. Next is bonding in a well-reinforced surface to mount the water heater onto. The empty tanks are relatively light, but if you add 45 to 88 pounds of water, you can see why a sound support base is important in a rough seaway.

Plumbing can be a bit of a challenge, especially when it comes to trapping air bubbles that will cause the engines coolant pump to cavitate. Every diesel engine circulates coolant with a vane-type pump, and though its long-term reliability is legendary, this type of pump is not a positive-displacement pump. That means it is not self-bleeding, so if air bubbles are not bled from the system, the pump ingests the air and spins little or no circulating water. This is one of the reasons why remote surge or top-off tanks for coolant are always placed higher than the engine itself. Its also why theres also a butterfly bleed valve on the top of heat exchangers.

In situations where the heat exchanger in a water heater has an inverted U-shape, with the inlet and outlet lower than the high point in the loop, care must be taken to rid the coolant circuit of all air bubbles when refilling with water and antifreeze. Air always seeks the high point, and this is another reason why some manufacturers say that their water heaters should be mounted at or below engine level, nearly impossible on many sailboats.

Globalization has made plumbing more difficult, and unless you have a good source for metric bronze pipe fitting, its vital to purchase metric-to-NPT conversion couplings (usually available from heater vendors).

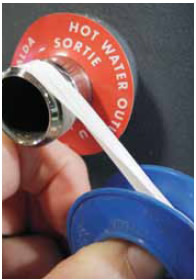

To keep pipe joints from leaking, use Teflon tape or pipe joint compound, and remember that hose barb-to-hose connections are much easier to make drip-proof with a hose clamp than the same connection made on a threaded pipe stub. Care also needs to be taken when connecting stainless-to-stainless joints, in order to avoid galling the threads. Many European marine plumbing manufacturers have switched to high-quality, investment-cast stainless steel. Nevertheless, these fittings are not as malleable or corrosion resistant as silicone bronze, so be sure to not over-tighten or allow stray DC current to run through these fittings