Iput a nice dent in the deck several decades ago when I dropped a wrench from the masthead. It scared the crew too.

I haven’t dropped anything since. I’m more safety conscious, my toolbags are more secure, and all of my essential tools are connected to me with bungees. Even when there’s no one below me at risk, the lanyard is cheap insurance. No single-hander who is forced to go aloft at sea to make repairs wants go back down, retrieve their tool, and climb again.

The first line of defense against dropping stuff is working methodically. The second is a firm grip. I learned while rock climbing that you never hand someone gear. Like a relay race runner at the baton exchange, you hold the tool out with a good grip on it and wait for your partner to take it from you.

It’s bad when you drop a tool, but it’s much worse when you drop a vital bit climbing gear down 1,000-foot cliff. Most tools are handled without lanyards for simplicity, but spring loaded tools like rivet tools and vise-grip pliers can get away from you. The potential harm from even a small tool is great.

The best safety lanyard length for hand tools is one that reaches from your left hip to the tip of your right hand at full extension, plus a few inches (photo 1). For me, about 4 feet is the right length, using about 4.5-5 feet of shock cord to make a lanyard. Power tool safety lanyards can be a bit shorter since you rarely use them at full extension, and you want to limit the drop as much as possible.

I like slim 2.5 mm shock cord for hand tools and beefy 5-6mm shock cord for power tools (photo 2). If the lanyard snags or is a little too short, the 2.5 mm cord easily stretches, and the stop is gentle if you drop something. Heavier cord will catch a power tool without jerking you off balance or slamming it into your kneecap.

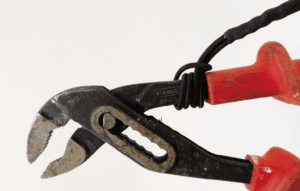

Threading the lanyard through a hole in the tool is the best option, but a klemheist or prusik (slightly more secure) knot holds even on straight shafts. It’s best if you can locate the knot above in a natural constriction (photo 3), but it will generally hold even on plated steel and a wrap of athletic tape will make it totally secure.

The loop in the tool-end must be long enough to wrap around the handle three times (photo 4). A 4-inch loop is good for hand tools, and a bit more for power tools (although these generally have a big battery bump and a luggage tag hitch around that is secure). The harness-end loop need only hold a carabiner. We like wire gate climbing carabiners, because they are light for climbing, inexpensive, best for clipping with one hand, and can also be used for climbing purposes, should the need arise. (The shock cord lanyard is NOT for climbing support. Obvious, but we had to say it.)

Because we’re attaching and detaching, and tying gripper hitches around tools, we like a smooth loop splice, ruling out bulky knots. A sewn eye, overhand loop, or even hog rings (larger sizes only) will work, but make it neat and cover it with heat shrink to eliminate snagging.