Photo courtesy of Quantum Sails; all other photos by Ralph Naranjo

Sailmakers and roller-furler designers deserve energy-saver awards for their success in reducing reliance on fossil fuels. What began in the esoteric big boat, big-budget racing arena has trickled down to club racers and is now being cross-decked to the cruising community. The legacy is a new way to handle off-the-wind sailing in light air, plus an ability to ghost along efficiently on a close reach in those all-to-familiar five-knot zephyrs.

The newest crop of top-down furlers adds more than a new twist to headsail handling. These systems are designed for nylon and other lightweight, off-the-wind sails dubbed A-sails, gennakers, asymmetric spinnakers, and other appellations referring to light-air, curved-luff sails. In this, part one of a two-part series, well compare basic features. Test results and final ratings will be published in part two next month.

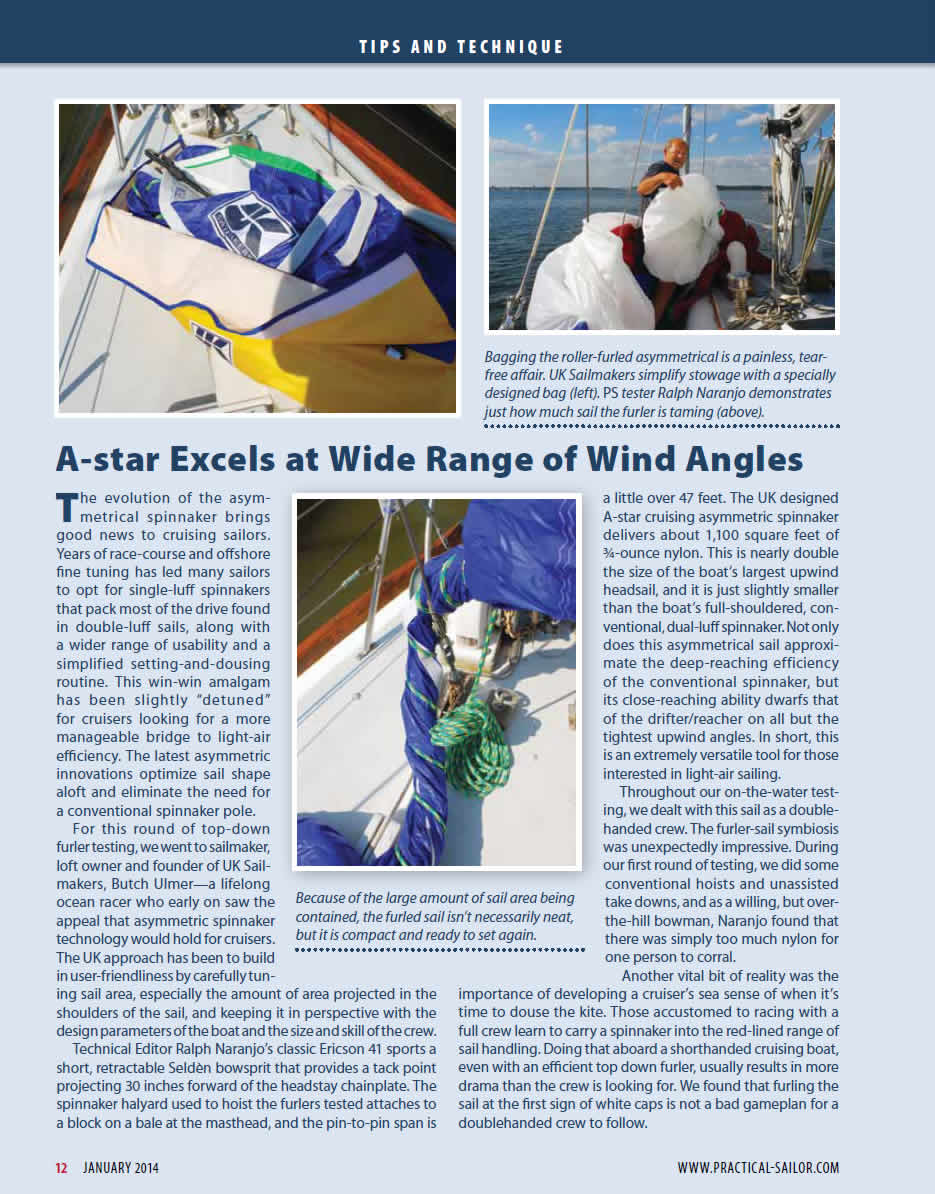

The furling units that tame A-sails give us a chance to hoist a cloud of nylon under complete control. During the hoist, the sail is fully furled, and once up, with sheets, run, and the crew at the ready, the sail can be easily unfurled via a tug on the sheet. Furling involves a reciprocal approach: You simply wind up the sail and lower the halyard. Spinnaker-dousing anxiety drops significantly.

The 1-2-3 process begins by steering a 90- to 120-degree heading to the apparent wind, easing the sheet and yanking away on the furling drum, which is driven by an endless loop. In no time at all, youre left with a snuggly rolled-up spinnaker, thats ready to be lowered to the deck and stowed away in its turtle or bag. By eliminating the loose nylon plunge toward the sea, spinnaker fire-drills can become a thing of the past. Shorthanded cruisers can cut engine run times in half and double the pleasure of being under sail.

In many ways, these furlers are similar to the endless line, foil-less furlers used to roller furl straight-luff, light-air drifter/reachers and code sails (PS, March 2008 and April 2011). In these earlier tests, we noted that light-air sails could be made with a stronger bolt rope or luff tape and flown as well as furled without a rigid slotted foil. The big upside was that it allowed these large sails to be hoisted and doused completely furled and completely under control. This approach was not appropriate for heavy genoas, or for that matter, upwind sailing in anything but the lightest of wind. What we did discover was that it was a splendid approach to handling large-sail-area, lightweight sails off the wind.

Among the units we tested in those earlier evaluations were Bamars Roll Gen and CDIs spinnaker furler. These are the early innovators in the realm of top-down furling. Both used a stiff torsion rope, but the CDI unit was troubled by its open drum configuration and tendency to let the furling line jump out of its slot. Despite the shortcomings of these early versions, top-down furling caught the interest of sailmakers and hardware designers. The second generation units that are now on the market have a lot more to offer.

What we Tested

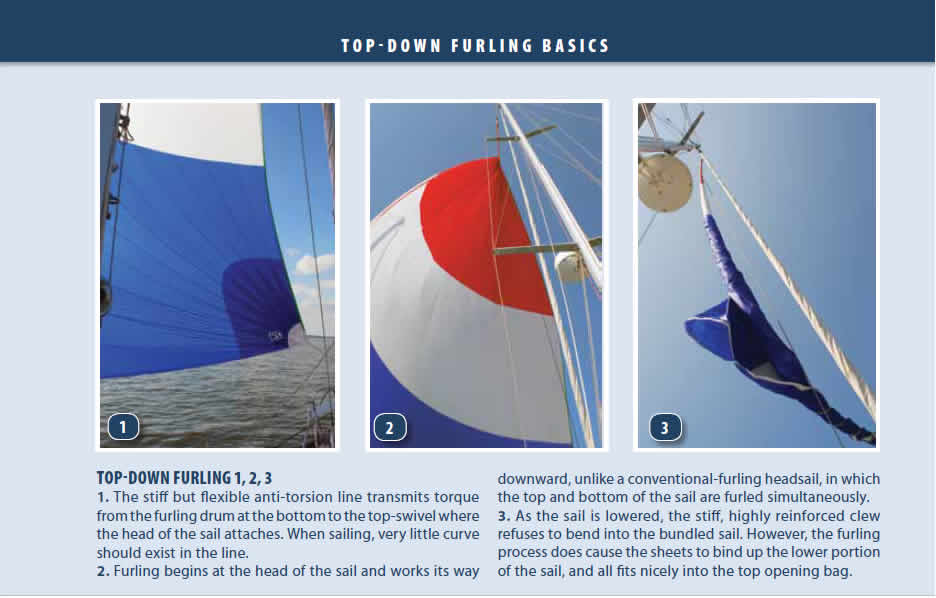

All five units in this test share a common thread: Each has a stiff anti-torsion rope (also called a torque rope) that acts like a semi-flexible drive shaft. Its purpose is to transfer rotary energy to the very top of the torque line where it attaches to the head of the sail and a free-spinning swivel. This torque is derived from a crew member pulling on an endless-loop furling line that turns a disc-like drum at the base of the sail.

The name top-down furler says it all. Each system furls a sail from the top down rather than from the bottom up. This is accomplished through two specific design modifications. The first is the swiveling tack that secures the sail to a non-rotating shackle just above the furling drum.

The purpose of this modification is to allow the drum to rotate without causing the lower part of the sail to roll up around its luff. Instead, the drum turns the anti-torsion line, and the rotational force starts furling the sail at the head, where it is attached to the anti-torsion line just below the swivel thats been hoisted on a spinnaker halyard. The anti-torsion line becomes both a drive shaft and a mandrel around which the sail furls.

Five Furlers Featured

All of the top-down furlers tested were designed to roll up and quickly unfurl lightweight, free-flying sails-especially those with a curved leading edge.

Each of these units works on masthead or fractional rigs, and even though they all look similar in block diagram configuration, there are significant design and engineering variations among the brands. Bearing systems vary, and pins, clips, and how the endless reefing line is reeved differ from unit to unit.

Anti-torsion rope details also varied. The Profurl Spinex unit adds a set of egg-shaped plastic bushings to the rope. Each maker also took a different approach to the ropes terminal fittings. So despite the fact that all of these furlers operate on the same general principle, theres enough variation to make each a uniquely different device.

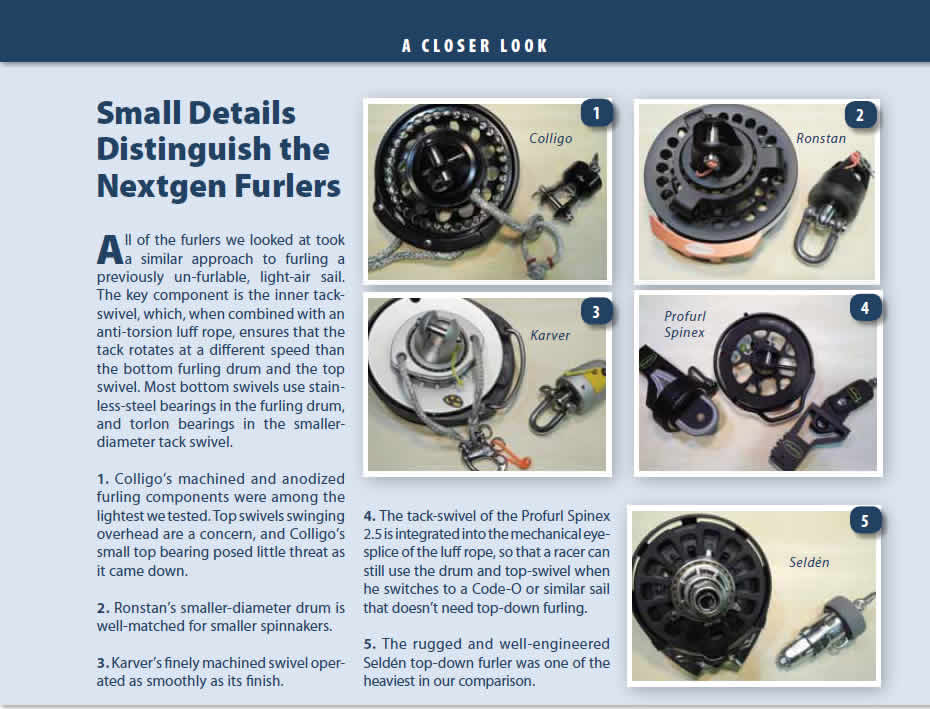

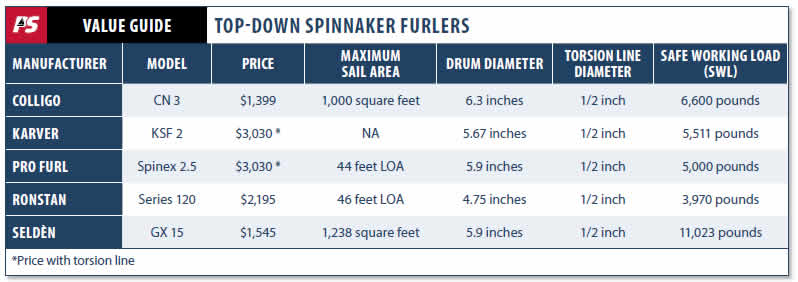

Colligo CN3S

The Colligo CN3s has a substantial 6.5-inch drum machined from a billet of aluminum, a nicely anodized finish, and spins smoothly on a sealed set of bearings. The upper swivel is light and compact, and incorporates a titanium shaft and clevis pin. Its Torlon bearings deliver a smooth spin under load, and although our test sails square footage exceeded the ratings for this furler, the unit did its job admirably.

We liked Colligos lightweight anti-torsion rope and fittings. We also liked the simplicity of the Spectra-fiber tail and thimble that acted as a tack point for an asymmetrical spinnaker. This could even be used as a lead for a longer, more versatile tack control line. The simple gate coverplate that allowed the endless furling line to be inserted or removed was durable but required a screwdriver to remove the fastener.

Selden GX15

Seldns GX15 displays a lot of careful engineering and a commitment to investment-cast stainless steel. Their glass-filled polyamide resin drum has 14 aluminum inserts to better grip the furling rope. Seldns endless-line furler utilizes a different approach to engaging the torque rope. Instead of doubling the line back around a thimble, it uses a compression sleeve-and-socket arrangement that captures the rope in a manner thats analogous to the way a mechanical terminal captures stainless-steel wire in standing rigging. This approach streamlines the drum and head swivels, but takes a little more time to fabricate. The result is a very slim and robust attachment. It also makes it more difficult to quickly disconnect the drum from the torque line.

Karver KSF2

Karvers KSF2 top-down furler uses high-resistance, stainless-steel ball bearings, incorporates a drum lock that can be engaged from the cockpit, keeps all parts captive, and utilizes a composite shell to protect the drum. Its a compact, innovative unit that includes a snap shackle at the base of the drum and a D-shackle at the top of a lightweight upper swivel.

The removable locking pin keeps the drum from unintentionally unrolling and allowing the sail to inadvertently deploy. The lock is disengaged by pulling on the furling line in the direction in which the sail has been furled and then pulling on the sheet. The torsion rope is finished at both ends with thimbles that fit the jaw of the drum and top swivel. And the endless-loop furling line can be quickly installed or removed without tools.

Profurl Spinex 2.5

Profurls Spinex 2.5 takes an interesting new tack. At first glance, the drum and upper swivel is like all the other top-down furlers, but the Spinex torque rope adds a new twist. In this case, the sail wraps around a full-length array of lemon-sized plastic bushings that rotate on the torque rope, changing the geometry of the furling process. Designers of the system say it improves the furl and prevents overrides.

Another interesting difference is that instead of adding a rotating tack to the furling drum itself, Profurl uses its efficient bottom-up furler and adds a large bearing tack fitting that connects between the furler and the torsion cable. These additions make the system heavier than systems of its competitors, and we look forward to seeing whether they also improve the furling process.

Ronstan 120

The Ronstan 120 top-down furler was the smallest, lightest, most compact unit we tested, and an evolution of its straight luff furler. The 120 incorporates a smooth spinning, dual-race Delrin bearing-supported tack ring sits just above the endless line drum and keeps the foot of the sail from furling until the upper portion of the sail is wrapped around the torque line. A clever pin-stop drum-lock easily screws in place, and a 90-degree twist of a split pin engages or disengages the lock. The aluminum parts are very nicely machined and stainless-steel components (shaft and bearing system) carry the primary tension and side loads.

Initial Observations

At the top of our plus list is the way these furlers tame a spinnaker. As we all know, in a conventional set or douse, the real drama usually occurs when the sail is halfway up or down. Thats when the head and shoulders can dive to leeward, and the sail is likely going swimming. When a nylon sail ends up in the water, even the most unflappable crew starts cursing. These are the moments when boat show spin is at its nadir. Preventing such encounters doesn’t mean you have to leave the spinnaker ashore-top-down furlers are a viable alternative.

The good news is that once you have the system set, things get even easier. Do the initial installation in five knots or less, because you must hoist both the spinnaker and the torque rope, which has a mind of its own. Flaking the rope out in large loops helps when hoisting, but the trick to is to make sure that both the sail and the stiff torque rope don’t try to latch onto a deck cleat or mast-mounted radar during the first hoist.

Once the sail is up and flying cleanly, check the tension in the torsion line-very little curve should exist. Also check how the drum and its hardware are aligning; no kinks or twist should be present and the endless-furling line should be fair. Some prefer to lead the furling line aft to the cockpit, while others like to work closer to the mast.

Once all the leads look good, simply have the person at the helm head off to a little more than a beam reach (90 to 120 degrees of relative wind angle), ease the sheet so most of the pressure is off-do not let it go completely. Then start hauling away on the endless line furler. At first, youll feel the load increase a little with no obvious result, but shortly, the head of the sail will begin winding around the upper part of the torque rope, working its way downward.

This furling process is different from slotted-foil headsail furlers. First of all, an asymmetrical is a more spherically shaped sail and attempting to make it behave like a window shade just doesn’t work. As the furling progresses from top to bottom, theres a point where a large part of the curved leech folds in and gets wound up in the rotation, When the high-cut clew finally reaches the rolled-up sail, a big bundle of the lower part of the sail remains loosely gathered. But as the sheets wind around the furling sail, they corral the sail right down to the foot.

With all secured, the douse is an easy, no hassle process that eliminates drama and delivers the conjoined torque rope and sail ready to be bagged and put away.

When it comes to the next hoist, all it takes is a connection to the drum, snap-shackling the halyard to the top swivel and a run of the already connected sheets and youre ready to sedately hoist away. Once all is in place, and youre on a heading 90- to 120-degrees relative to the wind, all it takes is a pull on the leeward sheet, and the biggest sail on the boat becomes the most disciplined.

The first lesson we learned was to measure carefully (twice) and precisely cut (once). The torque rope is terminated differently by each manufacturer and in part two of this feature, we will delve into specific differences and compare each approach.