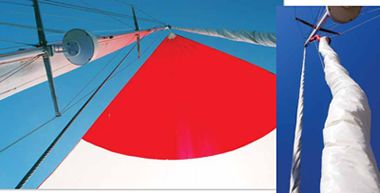

Top-down furlers have proven to be a legitimate means of taking the drama out of spinnaker setting and dousing, and they represent a new breed of hardware thats carefully designed and manufactured to be durable for the long haul. In Part I (PS, January 2014) of this two-part report, we introduced five top-down furlers, detailed how they worked, and made a good case for why short-handed cruising sailors should buy into a concept originally designed for hard-core ocean racers. In this article, Part 2 of the report, well take a closer look at the furlers, the test protocol, and the results.

There were no out-and-out losers in this test. Each of the five units we tested represents well thought-out engineering and quality materials. Across the board, these endless-line furlers, with their top swivels driven by anti-torsion ropes, successfully tamed the 1,100-square-foot UK Sailmakers A-Star-a cloud of well-shaped nylon that turned near calms into enjoyable sailing conditions. As testing concluded, PS Technical Editor Ralph Naranjo noted that a retractable bowsprit and any one of the five top-down furlers tested made his classic Ericson 41 a more versatile cruising boat. Some of the products made furling a little easier, others offered quick-change features testers liked, and the Profurl Spinex 2.5 even came with a string of plastic bearings that allowed the sail to spin off the furler with quick-set alacrity.

What We Tested

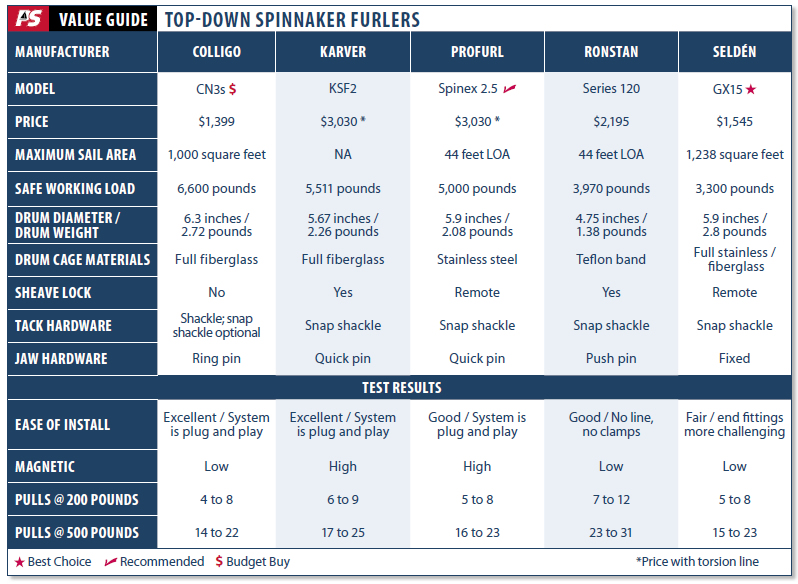

We tested five top-down furlers from top sailing hardware manufacturers: the Colligo CN3S, Karver KSF2, Profurl Spinex 2.5, Ronstan Series 120, and the Seldn GX15.

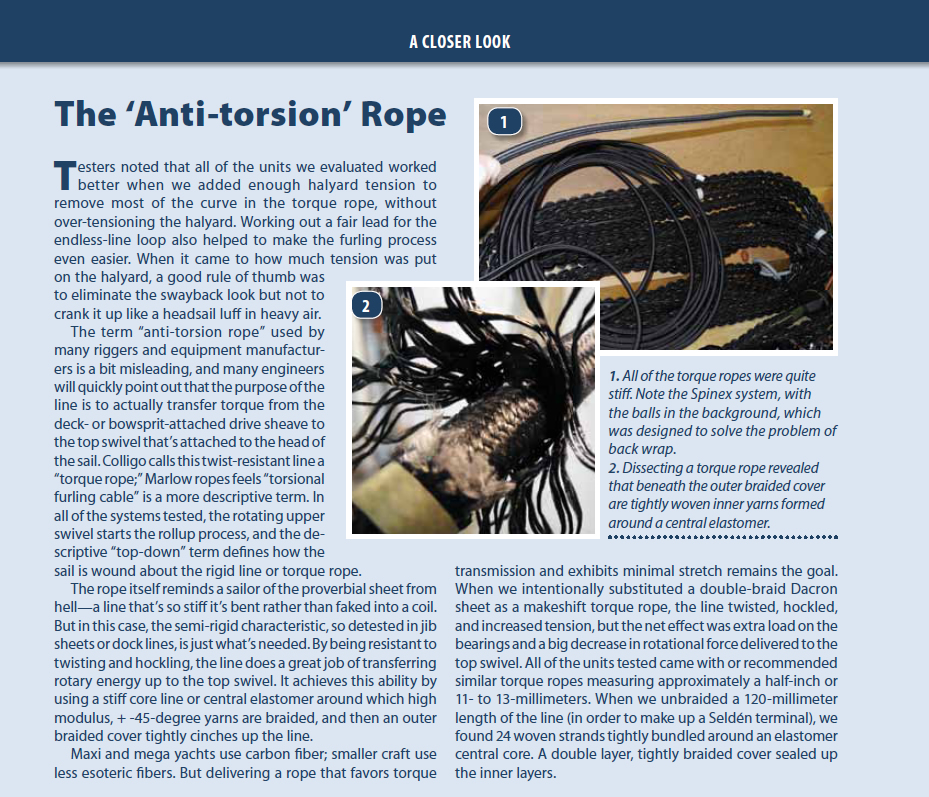

There are marked similarities and a few important differences among the units we tested. All worked on the same general principal: a deck-level sheave driven by a looped line spins an extremely stiff, axle-like rope, around which a sizable asymmetric spinnaker can be furled. The sail is attached to the top of the anti-torsion line (also known as a torque rope or torsional furling cable) and hoisted aloft on a spinnaker halyard. As detailed in last months report, the sail winds around this line starting at the head and working its way to the deck, hence the name top-down furler. This allows the drum to rotate without causing the lower part of the sail to roll up around its luff. The anti-torsion line becomes both a drive shaft and a mandrel around which the sail furls.

All of the products tested were designed to furl lightweight, free-flying sails-especially those with a curved leading edge. Each works on masthead or fractional rigs. All of the test furlers come with torque ropes, except the Ronstan. Bearing systems vary, and pins, clips, and how the endless reefing line is reeved differ from unit to unit. All feature half-inch-diameter anti-torsion lines, but the line details and terminal fittings varied. The Colligo CN3S was the only one to use a shackle tack; all others come standard with a snap shackle at the tack.

Each furler was put through its paces at sea and in the workshop. For specifics on the test protocol, see the accompanying How We Tested on right

Colligo CN3s

Colligos CN3s furler is built around a large-diameter drum with an efficient bearing package that delivers a smooth and easy furl. It features a 6.3-inch-

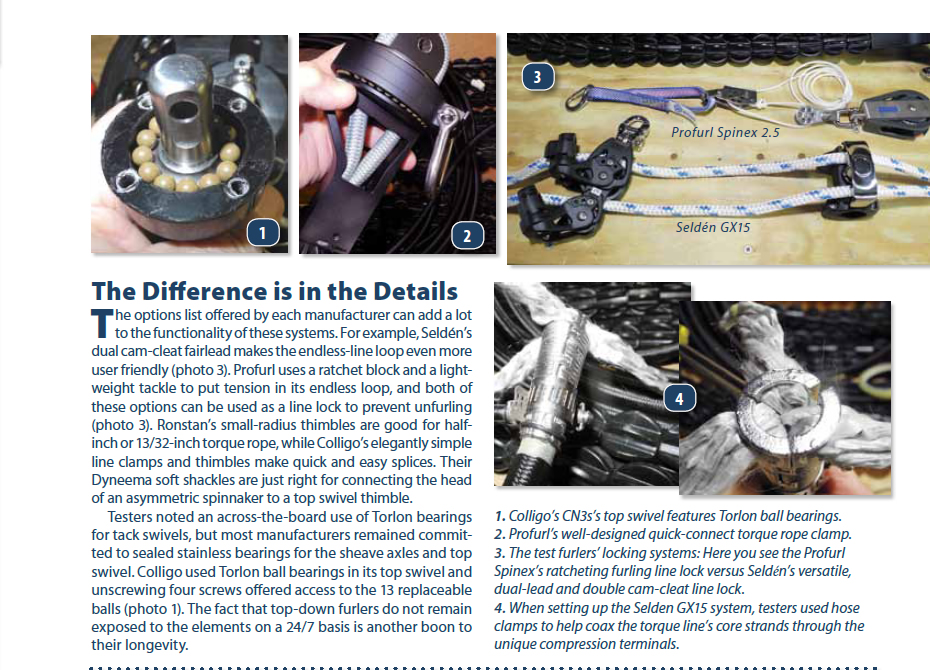

diameter, anodized-aluminum sheave rotating on a titanium, spindle-type axle and surrounded by a pan-like molded plastic cage. The sealed, angular contact bearings are housed in a compact, watertight hub and can handle thrust and axial loads. The lightweight top swivel runs on Torlon bearings, and the jaw uses a ring pin. A non-swiveling Tylaska snap shackle is optional for the tack.

We set up the endless-line drive using snatch blocks to insure a straight run to the furler. By placing another snatch block on the loop and tensioning it with a bungee cord lashing, we were able to keep the line taught and running smoothly during both the inhaul and outhaul process. In a permanent setup for this unit, or the other furlers, we would have placed some small but efficient bullet blocks on the endless line prior to splicing it together, and used them to fairlead the furling line.

Bottom line: Colligo hit a sweet spot with its large-diameter drum, moderate weight, ease of operation, and very favorable price. The least expensive in the test field, the $1,399 Colligo is the Budget Buy.

Karver KSF2

The Karver KSF2s superbly engineered drum and swivel combo sports nicely machined, user-friendly, singlehand-usable jaw pins and an easy-to-operate tack snap shackle, which makes setup and disassembly easy. Theres a removable drum lock that prevents unwanted unfurling, and the system works just like a window shade, requiring only a tug on the furling line to release the lock.

Prior to unfurling the sail during tests, we just hauled in a bit on the furling line, let go, and yanked away on the leeward sheet. When it came time to haul in the sail, we headed the test boat just a little below a beam reach, eased the sheet to spill the breeze, and hauled away.

It took a few yanks to deliver enough torque aloft to start the furling process, and as the sail wound around the torque rope, the sheet needed additional easing. Its important to watch the lazy sheet and make sure it does not get caught up in the furling sail. This is another reason we prefer working from the max beam/mast step part of the boat where all can be seen and responded to.

Bottom line: Karver got a nod of approval for jaw-pin operation and tack-shackle handling. It also scored points with its unique removable locking system controllable with a tug of the furling line.

Profurl Spinex 2.5

The Profurl Spinex 2.5 furler was the most complex of the top-down systems we tested. It had more hardware than the other furling systems, making it heavier and a bit more of a challenge to hoist. Testers also found the coiling and bagging process more complicated, especially on smaller boats. The tack swivel is part of the torque rope rather than the furling drum, and this allows the NEX drum to remain in play as a bottom-up furler after the spinnaker has been doused and stowed.

Testers liked the ball-like rollers on the Spinex 2.5s torque rope, a feature that makes unfurling the sail more like a well-orchestrated mark rounding than a typical cruising experience. The system also seemed more tolerant of snafus that would likely cause a back wrap problem on torque rope-only furlers.

The Spinex 2.5 features a nicely machined and anodized sheave, a stainless-steel sheave cage and little touches of elegance such as stainless-steel inserts where high-load carrying clevis pins penetrate the aluminum hub and swivel jaw. Testers noted the extensive use of high-tensile stainless for clevis pins and the central shaft of the furler, a feature that provides higher safe working loads but also yields a surface more prone to oxidation and crevice corrosion. Small increases in ferrous content allow stainless to be made into stronger alloys, but it also makes the metal more chemically and galvanically reactive.

Bottom line: Although hoisting and bagging were impacted by the bulk and weight of the additional gear, Profurls more complex design and bushing-like plastic balls made for the easiest in-and-out operation. It earns a PS Recommendation.

Ronstan Series 120

Sporting the lightest and smallest sheave of the test field, the compact Ronstan Series 120 furler still managed to get the job done during tests. However, once the wind picked up, testers missed having the leverage that larger-diameter sheaves provided. With less leverage delivered by the 4.75-inch sheave, it sent less torque to the head of the sail. So when furling in 15-knot conditions, we had to pull a lot harder on the endless furling line than we did with units driven by larger-diameter sheaves. Our shop tests also reflected the impact of less leverage.

In order to cope with decreased torque underway, we de-powered the sail by steering deeper, closer to 120 to 130 degrees (apparent wind angle), blanketing more of the breeze with the mainsail. The de-powered sail was easier to furl, but we had to watch carefully to keep the lazy sheet from getting trapped in the furling sail.

Sailors who furl the spinnaker at the first sign of white caps will find that theres enough torque in this light, compact furler to handle the task at hand, but the more adventurous sailors who ignore the signs and regularly get caught with too much sail up, a larger-drum furler and a 10-millimeter (rather than 8-millimeter) furling line would be a better option.

Bottom line: The lightweight Ronstan is a good choice for use with smaller spinnakers.

Seldn GX15

Seldns GX15 handled furling tasks quite nicely. Its a good combination of materials and engineering, carrying on the companys sensible commitment to investment-cast stainless steel. At the heart of the drive system is a 22/32-inch, stainless-steel axle shaft that snap shackles to the tack. At the opposite end of this 2-inch shaft is a unique compression fitting that locks the torque rope in place. The 5.9-inch-diameter sheave spins on a substantial, sealed, stainless-steel thrust bearing. We found no magnetic signature in the castings, but did note that the swivel axle was magnetic.

The split sheave in the endless-line drum is molded fiberglass thats held together efficiently with a multi-slotted interface and seven small stainless screws. This drum design allows for replacing the aluminum teeth that enable the swiveling sheave to tightly engage the furling line-an important attribute during higher-wind furling. Its torque-rope end fittings rely on a custom compression fitting rather than the easy-to-install thimble and clamp approach others use. Its more time consuming to assemble, but because its only done once, this is not a major drawback. (Those who have not had much experience with rope work may want to hire a rigger to make up these end fittings.) While the added end fittings mean more system complexity, it also means the GX15 offers a streamlined, permanently connected drum, torque rope, and swivel.

Bottom line: Seldn, a master of carefully engineered stainless construction, delivered a unit thats designed to stand the tests of time. It gets the PS Best Choice for a top-down furler for cruising sailors.

Conclusion

The bottom line is that we found each of these units had a certain nuanced spin that was all its own. All perform well and are well made. But when all was said and done, the Seldn GX15 captured the Best Choice award for cruising boats, the Colligo earned the Budget Buy pick, and testers Recommended Profurls Spinex 2.5. The others were nipping at the heels of the winners, and as mentioned earlier, there were no losers in this roundup of top-down furlers.

Amidst all of this top-down furler enthusiasm, wed like to offer a couple of precautionary thoughts. First of all, this technology allows a shorthanded crew to handle way more sail area than would be the case in a normal cruising context, and getting caught with an asymmetric spinnaker unfurled in too much wind is anything but a walk in the park. The second serious consideration is that although the furled spinnaker may look like other furled headsails, its not meant to remain hoisted and furled for prolonged periods.

One local sailmaker spoke of a client who had grown accustomed to leaving the sail up once furled. Apparently, while motoring through a calm, a chafed-through spinnaker halyard caused the furled sail to drop into the sea. Before the crew could get to the helm and switch off the autopilot, the sail, torque rope, and sheets got wrapped around the shaft and shut down the diesel in a very undesirable manner. The point being, top-down furlers make asymmetric spinnakers much more user friendly, but they also up the ante when it comes to the seamanship and decision-making process that goes hand-in-hand with their use.

For related PS articles and illustrations, check out the online version of this article.

You Might Also Like:

Test Offers a Chance to Preview Latest Bowsprit Options

Extending the Bow: Are Add-on Sprit Kits Worth It?

A Look at the Latest Generation of Genoa Furlers