A mainsail halyard shackle needs to be as reliable as an on/off switch on a table saw. Its a one-act pony thats counted on to perform perfectly each and every time.

These essential shackles fly under the radar and have become so much a part of every sailors routine that they are simply taken for granted. They terminate mainsail, mizzen, and foresail halyards aboard sailboats ranging from dinghies to mega yachts. We become so familiar with the hardware, that idiosyncrasies like a slightly bent clevis pins, damaged threads, or a misshapen stamped fork opening are tolerated. Shy of complete failure, we all too often put up with the familiar, even if it’s nearly worn out. Waiting for the shackle to fail may not be as cataclysmic as waiting for an upper shroud turnbuckle to fail, but when the mainsail unintentionally clatters down to the deck, life aboard undoubtedly gets more complicated. And so, we decided to take a new look at our old friend the mainsail halyard shackle, to define common failure modes, look over current options, and do some tension testing to see just what the hardware has to endure.

Halyard shackle function is pretty straightforward, at least it is when we compare metal hardware iterations of these shackles. Each U-shaped jaw and pin affords a quick and reliable means of attaching and releasing the mainsail halyard to the head of the sail. The first constraint to consider is the depth and width of the jaw and its ability to slip over the sails headboard and reach far enough down to allow the pin to go through the aperture.

The minimalist might say that a bowline or a halyard hitch are sensible stand-ins for a mainsail halyard shackle, but chafe on the knot as it reaches the sheave box at the masthead, and the chance of an incorrectly tied bowline or halyard hitch are valid downsides to using a knot.

Theres also the issue of losing hold of a halyard and watching it whiz toward the sheave box at the masthead; if a shackle is on the bitter end, the halyard stops when the shackle hangs up rather than dives into the sheave box. When a knot is untied, all there is at the bitter end is a heat-sealed or whipped terminus that will fly right through the masthead sheave and disappear inside the mast. Going aloft on another halyard to retrieve the shackle is a doable inconvenience. Going aloft at sea to run the mainsail halyard back down the mast, and capture it at the deck level exit point, however, is an ordeal worth avoiding.

What We Tested

The shackles we tested for this report represent a mainstream trend in design and materials; both domestic and overseas products were included. One trend we’ve noted is a commitment to stamped, high-quality 316 stainless steel. In the case of mainsail halyard shackles, loads are considerably less than what a spinnaker halyard snap shackle must endure, so the need for high-strength alloys is relegated to the big-boat arena where large mainsail area and high righting moments are the challenge. The average cruiser can justifiably favor a more corrosion-resistant alternative. The tradeoff in this case is that the more corrosion-resistant 316 shackle will need to be beefier in order to deliver the same strength as a more high-tensile alloy.

To cover all of the bases, we looked at the design and metallurgy of hard shackles and how the soft shackle revolution is stacking up against traditional hardware.

Testers evaluated metal shackles from Schaefer Marine, Ronstan International, and Tylaska. Ronstan and Tylaska each provided a little brother/big brother set of shackles; selection depends on boat size and mainsail area. Schaefer sent two stamped stainless-steel shackles and a heavy-duty investment cast screw-pin model. The soft, fiber shackle market was represented by a trio of different connectors from Equiplite and one shackle from Colligo.

How We Tested

In our shop-based portion of this shackle test, we point-loaded pins and loop locks to 50 percent of their safe working load (SWL). In the case of Ronstan, which lists breaking strength rather than SWL, we followed the policy of other manufacturers who define SWL as half the breaking strength of their product.

After the point-loading test, we eased the tension and operated the release mechanism. None of the products deformed as 50 percent of SWL tension was cycled on and off in our faux-halyard bench test. All release functions worked as expected.

A hands-on evaluation examined how each shackle behaved in onboard usage. We noted a change in mainsail hoist load propagation. Older tracks equipped with slides, a slot with slugs, or a slot with a boltrope, are all friction factors that affect halyard loading. With the older, more friction-bound hoist pathways, the halyard endures less peak loading because much of the energy transfer results in direct pressure from the sail to the spar, thanks to friction in the track and slides. Add more slippery slides and batten cars, and less stretchy sail cloth and halyard fibers, and the peak loads felt at the halyard shackle go up significantly.

All of the test products passed muster when it came to mid-day, flat-sea attachment and uncoupling. But in the middle of the night, when windblown spray scours the deck, a mainsail halyard may have to be swapped to the head of a storm trysail, and thats a whole different deal. Its a time when an errant halyard whizzing sail-less toward the masthead can be a very big deal; and avoiding such situations with a positive-latching shackle is the name of the game.

Ronstan

We tested a pair of Ronstan halyard shackles that were nicely stamp pressed from 316 stainless-steel stock. The RF1033 and the slightly larger RF1034 were relatively wide-jawed, deep-throated shackles that feature a very handy ring pin-fastened crossmember, which allows users to install the fitting on an already-spliced eye.

The simple, easy-to-operate, lever clevis pin made opening and closing a snap, even with gloves on. Testers especially liked this pin for daysailing and coastal cruising. The removable pin that allows you to slip a new shackle into a pre-spliced eye was also a favorite. The deep, wide jaws accepted a wide range of headboards, pressed and sewn in rings.

Bottom line: The many thumbs-up attributes-lever clevis pin, removable pin, etc.-combined with a good price earn the beefy RF1034 the Budget Buy.

Schaefer

Schaefer Marine sent us three of its stainless-steel mainsail halyard shackles: (in ascending size) the 93-42, 93-45, and 93-75. The two smaller ones, the 93-42 and 93-45, which were stamped out of a corrosion-resistant 304 stainless alloy, were carefully engineered and well suited to the job at hand. The larger investment cast shackle, the 93-75, was equally non-magnetic. With higher chrome and nickel content, these alloys will be less prone to pitting and crevice corrosion, though not as strong as higher-ferrous content martensitic stainless alloys.

The lighter-duty, stamped 93-42 and 93-45 are designed with a slotted clevis-pin hole and a simple twist-to-lock closure system. The heavy-duty 93-75 utilizes a dual-thread clevis pin that was threaded at both ends. The shackle was finely finished and got high marks for engineering and attention to detail.

Testers couldnt help but think of how well the double-threaded silicon-bronze shackle aboard Wind Shadow had worked over the years, and how similar in function this investment-cast stainless steel shackle appeared to be. A reliable clevis-pin closure is an attribute of every toggle-type halyard shackle, but to sailors crossing oceans, its an essential attribute. During a long passage, the mainsail may be up for a couple of weeks at a time, and reefing and unreefing can cause a shackle to snag or catch on a lazy jack or Dutchman line; thats when a double-threaded screw lock like the one used on the Schaefer 93-75 proves its worth.

Bottom line: Testers saw the 93-75 as a cruisers favorite because of its structural quality and tried-and-proven design. Its the Best Choice for cruising boats, and we Recommend the other Schaefer shackles we tested.

Tylaska

Tylaska, a master of sailboat hardware innovation, provided two of its top-selling halyard shackles for evaluation: the H5 and its big brother, the H8. These machined, high-strength, hard-anodized aluminum shackles have built-in thimbles that can be used in either 2:1 or 1:1 halyard configurations. A screw-type 17-4PH clevis pin positively locks the gate.

These halyard shackles have the highest strength-to-weight ratio of the metal products we tested. But how the aluminum alloy body and the stainless steel clevis pin will behave over time is a question well answer with our long-term testing.

Initially, it looked like we had two more examples of well-made pin-and-toggle mainsail halyard shackles, but when we took a closer look, we discovered some fascinating details. The first was the offset drilled holes for the clevis pin, an attribute that allows the lower radius of the pin-the part that transfers halyard tension into the toggle body of the shackle-to make contact with the toggle cheek, even though the pin diameter on one end is quite different than the diameter at the threaded end. This offset feature requires the use of a varied diameter, asymmetric, machined clevis pin, which in turn delivers more threaded surface area at one end but still allows the smaller diameter side of the pin to contact the toggle. This more evenly spreads the load on the shackle. Another interesting attribute is the loose fit of the threaded pin, which aligns as its tightened up and allows both shoulders to seat in the aluminum body of the shackle.

Bottom line: The Tylaska shackles are a good option for those looking for lightweight, metal mainsail shackles. The H8 is the Best Choice for use on racing boats.

Soft Shackles

When it comes to optimizing lightweight halyard-to-mainsail connections, fiber shackles have gained more than just the attention of performance-oriented sailors. We tested a trio of soft shackles from Equiplite: (in order of ascending safe working loads) the EQ105NS, EQ10NSM, and EQ105SSL.

The non-swiveling (NS) connectors are made of high-modulus Dyneema DSK-75 line that loops over a nicely machined anodized-aluminum thimble. The line lock encircles a recess in the thimble, which also provides a contoured radius for the spliced eye of a halyard. A Velcro strap encircles the line lock and keeps it from unintentionally disengaging. With a 70- to 90-percent weight savings over conventional stainless-steel halyard shackles, and a 50-percent saving over aluminum, its no surprise that these shackles appeal to racing sailors already invested in carbon spars, high-modulus fiber standing rigging, and esoteric rope halyards.

For lower working loads, theres the NSM shackle, which features a molded thimble rather than a machined, high-strength aluminum alternative. The quick-lock closure works just as it does with the NS soft shackle. A Velcro strap is used with both connectors to prevent an inadvertent opening. These metal-shackle alternatives are recommended for cruising boats in the 20- to 45-foot range. A factory coating affords good UV stability, but recoating every couple of months with an aliphatic urethane available from Equiplite is recommended.

The swiveling shackles (SSL) capture the halyard tail in the center of a high-strength aluminum fitting that has a polymer bearing and provides smooth efficient rotation. This loop-lock connector can also be used as a tack fitting.

In addition to the Equiplite trio, we tested a petite soft shackle from Colligo. The CSS102, which had the lowest SWL of the test field, is elegant in its simplicity; it is comprised of a loop of Dyneema SK-75 with a spliced eye at one end and a mini-monkeys fist at the opposite end. To close the soft shackle, the fist is shoved through the loop and the braided cover of the line slides down to lock the connection. A flexible O-ring is slid in place to keep the cover from moving when the load is off.

Bottom line: In our testing, these soft shackles worked as promised, but before we go out on a limb regarding longevity, we plan on seeing how the Velcro closure straps hold up, whether or not the alloy thimble on EQ105NS holds up, and what kind of splice slippage may occur. Although soft, fiber shackles have a wide range of applicable uses, we are not ready to recommend them for use as mainsail halyard shackles. Standby for the results of our long-term testing.

Conclusion

We looked over a cross-section of quality mainsail halyard shackles, but choosing the best has as much to do with how and what you sail, as it does with the products themselves.

For example, the owner of an ultra-lightweight racing boat likely would want to look closely at the Dyneema connectors; not only do they offer great strength and less chance of damaging the coating on a carbon spar, but the weight savings at the masthead holds appeal. However, recoating fibers with a urethane UV protectant every two months is quite an uptick in shackle maintenance.

Were holding off on recommending the soft shackles for halyard use until we have long-term test results to report. Until then, our top pick for the racing sailor is the Tylaska H8 shackles.

Cruisers, on the other hand, favor a very positive lock that has little chance of inadvertently opening, so screw threads are preferred. Such threaded clevis pins can be found in either Tylaskas high-strength aluminum H8 toggle-shaped mainsail halyard shackle or Schaefers 93-75 investment-cast, stainless-steel big boy. The latter tips the scale at almost twice the formers weight, but for those looking for durability and longevity, the extra 2.65 ounces isn’t too severe a liability. Its the Best Choice for long-distance cruisers.

Lastly, those looking for a cost-effective, easy to operate, and convenient to install mainsail halyard shackle should consider the Ronstan products we tested. Both proved to be durable and reliable 316 stainless-steel shackles that were easy to open and close, yet offered positive latching. We chose the larger RF1034 for our Budget Buy pick.

VALUE GUIDE: Mainsail Halyard Shackles

Brass is a pretty poor marine metal. An amalgam of copper and the much less costly and corrosion-prone zinc, brass’ reign afloat, at least in load bearing hardware, was short lived. But when copper is alloyed with less corrosion-prone metals, the result can be quite different. And although brass and bronze sound confusingly similar, their attributes tell very different stories.

Brass has held a decent shore-side reputation as a copperbased, yellow metal that’s reasonably strong, corrosion resistant, and able to be made into fasteners. However, when the potential for galvanic corrosion takes hold, and the presence of the chloride ion is added to the mix (all part-and-parcel of the saltwater environment), dezincification plagues brass. This is why marine metals experts early on turned to silicon, aluminum, tin, phosphorus, and nickel instead of zinc when it came to alloying copper and creating a stronger, more corrosion-resistant metal for marine use.

Among these zinc-free bronze alloys, silicon bronze represents the metallic sweet spot that combines strength, corrosion resistance, malleability, ductility, and a cost-effective price point. More esoteric alloys like high-nickel-content Monel are just too costly to be widely used in the recreational boating market. But silicon bronze was an alloy of choice for nearly a century.

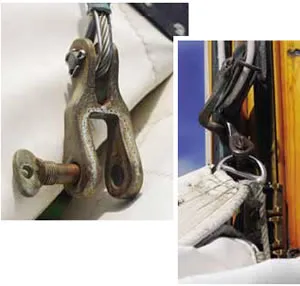

One of its most redeeming characteristics is its tolerance of cycle loading and fatigue-inducing stress. Parts machined or cast from silicon bronze tend to physically deform before they finally break. This gives sailors a chance to visually observe signs (elongated holes, twists and bends) indicating that hardware needs replacing before complete failure mandates more complex repairs.

Looking over the running rigging aboard PS Technical Editor Ralph Naranjo’s Ericson 41, Wind Shadow—which has been revamped three times in almost 40 years of ownership—we realized that the silicon-bronze screw type mainsail halyard shackle was part of the boat’s original kit when launched. The reason it’s still in use today has nothing to do with nostalgia, and everything to do with design, engineering, and metallurgy. Silicon-bronze hardware is moderately strong and seriously corrosion resistant, making it an excellent choice for standingand running-rigging hardware. Due to stainless steel’s initial strength-to-weight advantage, and probably its inherent shiny appeal, it has upstaged silicon bronze as the metal favored for sailboat hardware. Ironically, the aesthetic appeal of the bright, highly polished stainless tipped the scale, and the practicality of the green, self-protected surface of oxidized bronze lost out.

But it’s interesting to note that, over the years, most of Wind Shadow’s stainless snap shackles, bow, and D-tack shackles have crevice corroded, cracked, and either failed or were replaced in the nick of time. The longevity award for mainstream marine metals favors silicon bronze.

For the first 10 years, Wind Shadow’s silicon bronze halyard shackle had a chrome-plated surface, but as time went on and weathering took its toll, the shiny finish was replaced with a green patina. This verdigris actually protects the metal from more active oxidation. Add to this the way threaded silicon bronze self-lubricates and will not gall, and you can see why it was a great choice for a double-threaded halyard shackle. Today, a close look at the shackle reveals considerable surface pitting, but its substantial dimensions make up for this minor aesthetic shortfall.

A couple of years ago, we sailed aboard the L. Francis Herreshoff classic Ticonderoga and couldn’t help but note the deck hardware—a testimony to the utilitarian nature of silicon bronze. Built in 1936, the big ketch has gone through a handful of serious refits. Its deck and hull planking have been replaced, spars remade, and engine replaced, but much of its original, green-tinged silicon bronze deck hardware has stood the test of time. Sadly, this great material is disappearing from the waterfront, replaced by shiny stainless steel, a good metal but one with less longevity. The only place you’ll find silicon bronze shackles these days is used-gear chandleries.