In the summer of 2014, Fortress Anchors, the maker of a popular aluminum Danforth-style anchor, conducted a series of anchor-holding tests in Chesapeake Bay, an area renowned for its soft mud and oyster-shell seabed. Its aim was to examine the performance of its products against some of the newer anchor designs introduced since the companys previous head-to-head tests, which were held in San Francisco Bay in the early 1990s.

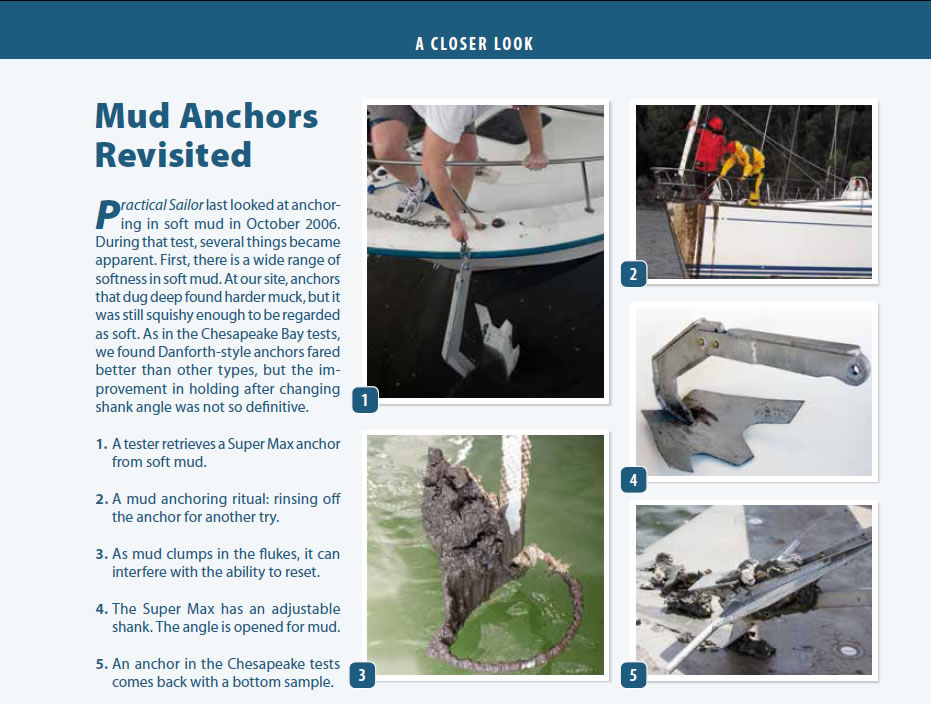

Practical Sailor carried out its own series of anchor tests in a mud bottom in 2006 (see April 2006 and October 2006 issues), and those tests bore out a commonly known fact: Danforth-style anchors, which feature flukes that are proportionally larger than other types of anchors of the same mass, tend to hold better than older, plough-style anchors in soft mud. When Practical Sailor was invited to witness Fortresss test, editors were initially skeptical; the playing field seemed heavily tilted in Fortresss favor. In the end, however, it was a busy test schedule, not outright skepticism, that prevented our attending.

After reviewing the test results, including video record of the well-documented tests, we are convinced that the evaluation was carried out fairly, and that the test methodology offers some important insight on anchor performance. Although we would change some aspects of the tests to suit our own curiosity, we believe the results are worth reporting-and putting into context. The findings will be particularly useful to those sailors who frequently anchor in shallow, soft bottoms. The test procedure offers an alternative to previous methods used by Practical Sailor (and others), and the results themselves are interesting, if not eye opening.

Photos courtesy of Fortress

The Mud Challenge

Soft mud seabeds are relatively common, particularly in shallow estuaries and at the mouths of large rivers. In many cases, the soft mud gives way to clay or harder, packed sand, so that if an anchor penetrates deep enough, it finally has something to bite. But in other cases, the mud is soft and deep. Such areas are avoided for long-term anchoring-and consequently, anchor testing-because of the difficulty in finding good holding. As a result, most anchors are optimized for harder bottoms. One interesting implication from this test is that some design elements engendered by this logical bias toward hard-sand bottoms can actually hinder anchor performance in soft mud.

What Was Tested

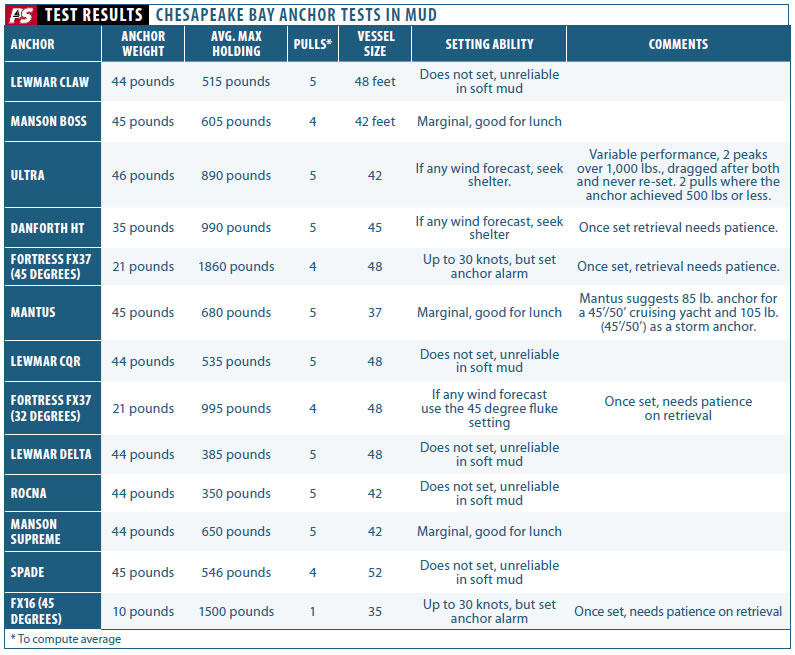

The anchors were all chosen based on the recommended size for a sailboat of about 45 feet. The only exceptions were the Fortress FX16, which was recommended for a maximum 35-foot boat, and the Mantus, a diving-type anchor that is recommended for a 37-foot boat. The Fortress testers narrowed the range of anchors to those they deemed as commonly available in America. This excluded some popular designs available in Europe or Australia, such as Plastimos Kobra and Brittany anchors, Anchor Rights Excel and the Evergreen, and the much-copied Bugel from Germany. Also missing, but available in America, was Mansons Racer, another aluminum Danforth-style anchor. Additional noteworthy omissions were the Super Max anchor from Creative Marine design, an anchor that features an adjustable shank for better holding in soft mud and is used by commercial boats in the Mississippi Delta, and the XYZ anchor, an odd-shaped and relatively obscure anchor that excelled in Practical Sailors soft-mud testing.

Fortresss test field included the following anchors: a 44-pound claw (Bruce-type) and a 44-pound CQR-type from Lewmar; a 45-pound Boss and 44-pound Supreme from Manson; a 45-pound galvanized anchor from Spade (Spade also makes stainless and aluminum versions of this anchor); a 46-pound, stainless-steel Ultra anchor from Quickline USA; a 45-pound Mantus; a high-tensile Danforth HT from West Marine; a 44-pound Rocna from Canada Metals Pacific; and two, 21-pound FX37 anchors (one with the adjustable shank set at 32 degrees and another with the adjustable shank optimized for mud at 45 degrees); and one 10-pound FX16 with shank set at 45 degrees from Fortress. Average holding power (collated from the raw data provided to Practical Sailor) for each of the anchors is in the accompanying table.

Test Methodology

To evaluate anchor holding capacity, anchor testers have usually turned to one of two primary techniques: shore testing, setting the anchors off shore from a beach or pier and pulling from the shore using a fixed speed winch; or sea-testing from a large, powerful motor vessel with the vessels engines and propellers providing the load. In both cases, a load cell is used to record loads.

Both of these techniques have advantages and weaknesses. Generally, the areas used for testing from shore are too shallow for actual anchoring. Shoreline testing also tends to limit the cross-section of seabeds available-finding a truly soft mud bottom accessible from shore can be especially difficult since it can be expensive to build or set a piling in a truly soft mud bottom or the adjacent terrain (often marshland). As for the advantages of shore testing: Beach or pier testing is easy to control, tests are easily repeated by others, and it is often possible to video record or physically measure the movement of the anchor.

Testing from a moving vessel opens up more testing areas, and more realistically replicates actual anchoring. However, this method, too, has its disadvantages. The power applied to set each anchor is not so easily controlled, and only in areas of clear visibility with the assistance of a diver can the actual setting performance be videotaped, measured, or visually evaluated. In soft mud, setting an anchor from a vessel is impossible for a diver to observe because of the murky conditions.

The Fortress procedure involved the use of the University of Marylands research vessel, R/V Rachel Carson. The vessel has two 1,205-horsepower diesels, two Hamilton jet drives, and a stern-mounted, 4,200-pound winch. Using a Dynamic Positioning System (DPS), the vessel can hold itself in a fixed position (within about a 10-foot-radius circle). Instead of a load cell, the vessel was equipped with a tension meter that measures both speed of retrieval and tension of the line. A computer collected all the data from the tension meter.

For all the tests, the rode consisted of 20 feet of 3/8-inch G43 chain; the rest of the rode was 5/16-inch wire. Although the 5/16-inch wire was adequate for this test, in our experience, this setup would be underpowered for testing the same size of anchors in hard sand, where they would generate much greater holding power.

Initially, testers had considered using the engines of the vessel to set and load the anchors, as had been done in previous tests. However, to eliminate the wide variability attendant to this method, the team relied on the boats ability to hold steady in a single spot. While the engines held the boat in place, testers used a stern-mounted winch to apply the load.

Five different locations were chosen for testing, and the anchors were tested in a circumference around a single spot, with the vessel centered each time in the same place for each location. With 12 anchors to test, this meant that each anchor was tested about 30 degrees apart. This avoided problems that can occur when one anchor is tested in the furrow dug by another, but it did not altogether eliminate the bugaboo of all anchor tests: variations in the bottom.

For each set, testers laid out enough cable to provide a 5:1 scope (depth-to-rode ratio of five-to-one), and then added an additional 100 feet of cable. Each anchor was deployed by hand. After deployment, the vessel was re-located in the circles center and the anchor set or pulled at a fixed rate of 10 feet per minute (for a total of 10 minutes), until the 5:1 ratio scope was achieved. The maximum load recorded during the course of each pull was logged and then included in an average for each pull.

After 48 total tests (at four locations), the protocol was changed for a final round-one test per anchor. For this final comparison, testers deployed the anchors to just twice the depth (2:1 scope) and added an additional 15 feet of cable, set the anchor with a 200- to 300-pound load, and then followed the protocol for the previous test (deploying 5:1 scope plus 100 feet, then retrieving the 100 feet while recording maximum load).

The test location was off Solomon Island in Chesapeake Bay. The location was specifically chosen to be free of any significant wave actions. Depths were about 30 feet from the vessels roller, resulting in about 250 feet of total rode (150 feet to achieve the 5:1 ratio, plus 100 feet) paid out for each test. The seabed was not defined, but judging from samples bought up by the rode and anchors, the top layer looked like slightly thickened sump oil. Those anchors that developed a fair amount of holding power were caked in a thick, firmer mud with oyster shells-presumably located at a deeper depth.

To provide some comparison, a 45-pound mushroom anchor (a similar weight to the tested steel anchors) was tested for holding capacity, or resistance to dragging. The 20-foot length of chain alone was also tested. The mushroom returned a resistance to dragging of 150 pounds-not much different than some of the anchors. The rode alone provided 50 pounds of holding. (An all-chain rode would, of course, have provided greater resistance).

Bottom Variables

Practical Sailor noted a number of issues with the test procedure. With anchors tested in a circle, an anchor in the 12 oclock position is set 500 feet from the anchor that is set at the 6 oclock position. The bottom could vary widely between these two locations. We noted that some adjacent anchors often yielded better results, suggesting that one side of the circle was more favorable than the other. However, testers mitigated this variability by testing in five different locations.

Another problem was that the ships dynamic positioning system had a time lag, which caused it to over-correct, resulting in a series of peak loads, rather than a steady, increasing load. For example, when an anchor set, the vessel was winched toward the anchor, this caused the DPS to activate and attempt to relocate the vessel. Sometimes the vessel, because of its momentum, over-corrected, and in trying to re-center itself (move toward the anchor), it caused the load to go slack. So for each pull, a series of on-and-off cyclical loads was common. The same thing occurred when an anchor hit a snag, or area of firmer seabed. However, during the data analysis, these cyclical loads could be averaged out, and once the DPS settled down, the loads were smooth.

A further problem we noted was that anchors are seldom set or deployed with such a long rode. The smaller-scope test helped compensate for this, but this second-round test favored anchors such as the Fortress (at the 45-degree shank angle) that are well suited to setting in soft mud with short scope. The change in protocol did not appear to help the poorly performing anchors, and no attempt was made to optimize the setting scope for each anchor.

The protocol also demanded that each anchor be tested for the entire duration of the pull, 10 minutes. Consequently, even though an anchor did not set at all, the full 10 minutes of pull was completed, yielding a pathetic average for some anchors in some test locations.

We would have liked to have seen at least one test using more than 20 feet of chain, since longer lengths (at least 60 feet) are more common on cruising boats of this size. Based on our own testing (see Practical Sailor, February 2014 online), it is likely that the reduced resistance in the wire (as compared to chain or thicker nylon rode) would give a slight advantage to the Fortress anchors that were configured to dive deeper in the mud (45-degree shank angle).

Lackluster Results

All of the anchors struggled to set at least once. Some, including anchors that have fared very well in our own testing, struggled in all five tests. This fact emphasizes a point that weve made frequently: There is no perfect anchor for all conditions.

Most anchors did actually set, in that they developed more holding power than the 45-pound mushroom, but as the load increased, the holding power then decreased. This rise to a peak and then a drop-off is normal in anchor testing; seabeds are inconsistent and the longer or further you pull an anchor, the greater the chance of hitting an obstacle (oyster shell, old shoe, buried log, etc.) that can inhibit holding. In soft mud, such snags usually cause an anchor to climb out of the mud and drag-often with a big clump of mud in its maw, making it impossible to reset-developing very little resistance. The computer-generated plots of load-against-time developed during the testing seem to indicate that some kind of clogging or snagging might have occurred in several instances.

Upon retrieval, many of the anchors had hooked on oyster shells; sometimes, the toe of the anchor-the pointy end that digs in-had pierced a shell. On one occasion, the Mantus hit a snag, but then pulled free. Although the load was not high, the anchors roll bar bent at one of the bolt attachment points. This vulnerability was pointed out in our review of the Mantus (see Practical Sailor, April 2013 online). No other anchor suffered any damage during testing.

Not surprisingly, the Fortress FX37 (see Practical Sailor, September 2013 online for our last test of this anchor), when optimized for soft mud with the fluke angle set at 45 degrees, was the eventual standout performer. The Fortress, with its fluke set at 32 degrees, and the Danforth HT (which has a the same fluke angle and a nearly identical design) developed almost identical holding power, but they were insufficient for anything except as a lunch hook or in balmy overnight stop. The Ultra was not as good as the Fortress or Danforth, although it provided enough holding power for a lunch stop. None of the other anchors instilled any confidence at all. Some were no better than dragging a 45-pound mushroom anchor.

It was interesting that ostensibly similar anchors produced startlingly different results. The Ultra and Spade anchors-both featuring shallow, concave flukes-produced different holding power. Likewise, the Mantus, Rocna, and Supreme-all featuring a roll bar and concave flukes-produced different results. To us, this suggests subtle differences in design that seem to matter less in hard sand, but can make very large differences in performance in soft mud. (These differences also might bear out in very soft sand.)

Additionally, old fashioned designs like the Bruce-like claw and CQR anchors from Lewmar yielded holding power that was close to or better than that of the more modern Spade, Rocna, and Manson anchors delivered.

The Roll-bar Dilemma

The Rocnas poor performance was an eye-opener. The fact that it never set during testing suggests that it might have landed upside down and that the self-righting effect of the roll bar does not work in a soft seabed. This effect might also occur in soft sand, and the results suggest that this might be a problem for other concave-type anchors that have roll bars but lack a weighted toe. (The Manson Supreme, which has a roll bar, but also has a weighted toe, performed much better.)

Most anchors rely on a firm substrate to self-right, and this seems especially true for anchors with roll bars. It is logical that a roll bar would be little or no help in a bottom that is too soft to roll on-in which case, a weighted toe would come in handy. However, the Mantus, which has a roll bar and lacks a weighted toe, seemed to defy this logic. Compared to both the Rocna and Manson, it fared pretty well in the Chesapeake mud.

As we pondered this puzzle, we were reminded that in our own tests, the hydrodynamic effect of water flowing past the flukes of the Mantus seemed to help it self-right. The Mantuss tendency to self-right during deployment was most obvious in our tests when the boat was moving in reverse-the direction of the set. We suspect that the protocol used during the Chesapeake Bay tests-with the Rachel Carson moved back toward the center point once the 20 feet of chain was deployed-could have promoted this self-righting.

Regardless, the reliability of the Mantus and others of its ilk should be viewed with caution in soft mud. There is evidence that the weighted convex and concave anchors-Delta, CQR, and Spade-also self-righted, but the amount of holding power for all of these anchors was inadequate for anything but a lunch hook.

Based on the holding-power numbers, it is obvious that the Ultra anchor self-righted. Its holding power was 20-percent greater than its nearest rivals of similar designs-the Boss, Supreme, and Mantus-but, again, none of these anchors, which have fared well in our tests, generated reassuring numbers in soft mud.

Conclusions

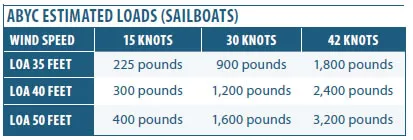

We looked at the raw data for five pulls and discarded those pulls that we would have abandoned had we actually been anchoring in real life. (The number of pulls is included in the table.) We then averaged the remaining maximum holding capacities. Finally, we compared these numbers with data from the American Boat and Yacht Council (ABYC) for the projected load on a 35-foot, 40-foot, and 50-foot boat at various wind speeds (shown in the table).

It is worth noting that anchor makers advise setting the anchor under power. (The amount of power recommended varies between 50 percent of maximum RPM to full RPM.) Generally speaking, if the owner of a 45-foot cruising boat tried to set each of these anchors under power in the test area, in most cases, he would know when an anchor wasnt well set. However, depending on how much power was applied while setting the Boss, Supreme, and Mantus anchors, each of these might appear to be well set. But according to ABYC data, they would begin dragging in about 20 knots of wind. (The Ultra would hold a little longer, maybe until 24 knots, according to the ABYC data.)

It also is worth noting that our own tests (see Practical Sailor, November 2013 online) have shown the ABYC data to be very conservative (as much as three times the actual loads), but we see nothing wrong with a healthy safety factor, especially when it comes to anchoring. And one needs to keep in mind that the ABYC data does not include wave-induced loads.

Aside from the obvious challenges of soft mud when anchoring, another take-away from the Fortress tests is the long distance required for setting. In our own tests in sand, an anchor would generally set within two to three feet from where it landed on the bottom. This test suggests that setting in soft mud would require more than 100 feet of dragging before the anchor finally penetrates deep enough to take hold.

In the end, Fortresss testing underlines what Practical Sailor and others have pointed out before. The Fortress anchor, especially with the flukes set at 45 degrees, is especially adept at holding in soft mud. If you do not carry a Fortress, or other large Danforth-style steel anchor, and winds are forecast at greater than 25 knots, you should not place much confidence in a soft mud bottom.

This conclusion, however, doesn’t mean that a Danforth-style or Fortress anchor is the best overall anchor. In our own tests, Danforth-style anchors have done well in range of bottoms and in simple veer tests. However, their flukes are more vulnerable under extreme loads, and they can have trouble resetting if they get pulled out and the boat is dragging quickly. Mounting them on a bow roller also presents challenges. To get a clear picture of holding ability in other bottoms, be sure to review our past tests available online, and look for our upcoming e-book compiling all of these tests, to be released in the fall.