A well-secured boat in the best-designed marina can’t be expected to survive a direct hit from a hurricane. Major boat-insurance companies recommend hauling out and tying down your boat, but that isn’t always an option, nor is it any guarantee.

In a previous issue, Practical Sailor explored a time-tested alternative to hauling out: escaping to a hurricane hole. In that report, we discussed the equipment and techniques that boatowners can use to secure a boat in well-protected water-usually a river or estuary far from the storm surge area. But what happens if you have no other option but to remain in your marina? Besides double-checking your insurance policy and making heartfelt pleas to Poseidon to spare you, there are measures you can take to secure your boat in its slip.

Obviously, you want to have your boat well-fendered against inevitable collisions with the dock pilings and other boats. But the most important task will be arranging the mooring lines to your best advantage. Once storm surges exceed 8 feet, all bets are off in most marinas, but with storm surges of 8 feet or less, you may have a chance. The question is: Whats the best way to secure the boat?

Some suggest doubling up on dock lines; others recommend cocooning the boat in a spiderweb of lines. The philosophy in both of these cases is that you can never have too many lines.

The problem with many modern boats, however, is that there simply arent enough large cleats that can handle two lines. Deck cleats and chocks are seldom large enough to handle two properly sized dock lines with chafe gear, so backup lines are often secured to winches, rails, and chainplates that arent designed for these loads. (See Practical Sailor Takes a Close Look at Boat Cleats, PS March 2010 online.)

Doubling lines often introduces chafing where two lines meet or cross, whether both are tensioned or one is left slightly slack to serve as backup. Either way, the lines saw against each other. Doubling lines often requires more careful rigging than one would think.

The spiderweb approach faces similar shortcomings. While the spiderweb principle has merit, it often lacks design or engineering. Its a sailors best guess at what might work, and it doesn’t solve problems with chafe and the lack of reinforced deck points where lines are doubled-up.

What if you are away from your boat for a long period? More than likely, your spiderweb of lines is cutting across parts of the deck that normally would see no wear, and even the gentle back-and-forth movement caused by marina traffic will begin to wear grooves in your teak or gelcoat. Is there not a solution that could be just as secure, but use the boats dedicated cleats and chocks? We were sure there was, and we sought out a way to test our ideas.

An essential element in securing your boat in a slip is a spring line, the line extending forward or aft from a cleat near mid-ship to a fixed point ashore. Sadly, many production boats are still not designed with mid-ship cleats that are suited for spring lines. But most cruising boats longer than 35 feet now have them.

Spring lines are eminently useful in arriving or leaving the dock. They are used to help stop the boat or to position the boat in the slip while docking in a crosswind. One technique that is handy for some slips is to have a spring line, always deployed, stretching from the dolphin piling to the farthest dock cleat on the same side. Coming into the dock, it is a simple matter to pick these up. Once you are in the slip, you can use them to easily adjust the boats position. And when leaving the dock, a full fore-and-aft spring can serve as a handy place to drape the stern line if you miss the dolphin. The full fore-and-aft spring line is also handy in a blow, and thats the topic of this article.

What We tested

Our test boat for this spring line evaluation was a 34-foot by 16-foot catamaran in a 41-foot by 19-foot slip. This is a relatively tight slip for the boat, particularly after you take into account the effects of storm surge. Our tester had always used bow lines, stern lines, and fore/aft spring lines on both sides to dock in this slip. Initially, the springs were added to reduce surging in gusty conditions. The spring lines are also a huge help when backing into the slip. They are invaluable when singlehanding in a crosswind. Thanks to the efficient use of these spring lines, the boat has survived several tropical storms and countless thunderstorms without chafe or damage.

Until recently, the testers spring line-tying routine was merely an intuitive approach. He was confident that the lines were plenty strong for anticipated loads and that chafe was the real enemy, but hed never actually measured the loads at the dock until he embarked on this experiment.

How We Tested

To determine the effects of storm surge on dock lines, we built a simple wood and string model of a monohull (Catalina 36) in an average size slip (45 feet by 16 feet). (See How We Tested on right.) This helped to visualize how a boat moves with different line arrangements. We then released lines in different combinations to simulate failures, observing how the boat shifted. Would it stay off the pilings and within the slip? How did the added slack we might need to compensate for storm surge affect the boats position in the slip?

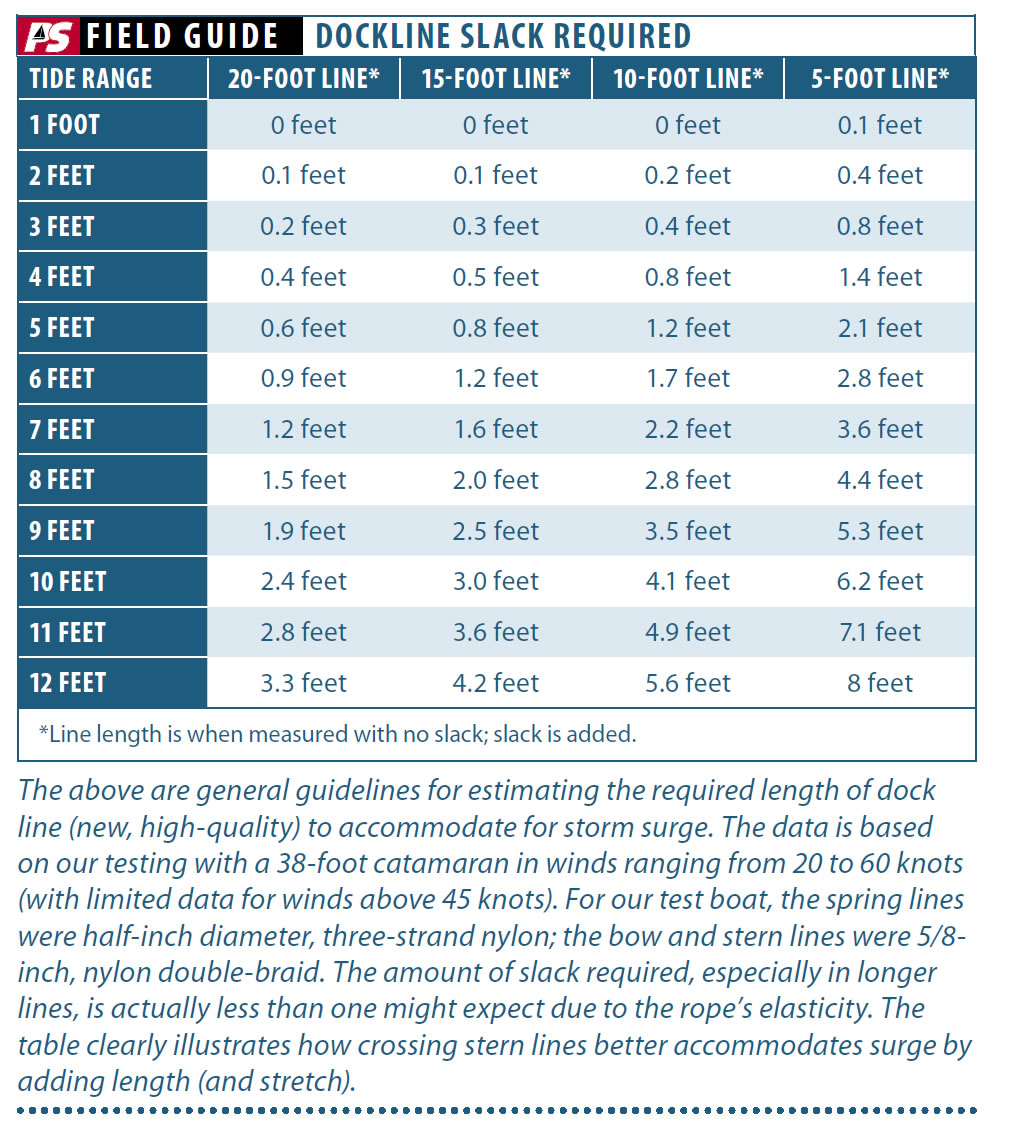

The experiment involved some relatively simple geometry: There should be enough slack in the lines to accommodate the boat rising due to surge, bringing the lines just taught at the peak. On longer lines, there may be far less slack than you expect. Be sure to check out the data table that accompanies the online version of this article; it suggests the amount of slack to leave in a line based on predicted tidal surge.

There are two clear lessons from the table. First, spring lines require far less slack than is intuitive or than most sailors allow. Our test boat lives with about 1 to 1.5 feet of slack in each of its 20-foot-long spring lines. This allows an adequate amount of stretch, without overloading, through surges up to 8 feet.

On the opposite side of the spectrum, short, little stern lines can’t manage storm surge. They become stretched beyond their safe working loads. Longer lines that are protected for chafe allow for more stretch.

After practicing with the model boat, we moved to our test boat and measured dock line forces. We measured with slack in the lines ranging from a few inches to two feet. Sailors constantly debate whether it is better for the boat to move more freely in the slip or to restrict its ability to gain momentum in a gust. Our observation at all wind speeds showed no significant difference, except when one line failed. In those cases, more slack in the lines put the boat at a greater risk. For this reason, an arrangement with adequate-but not too much-slack in the lines seems preferable.

On the Water Testing

To test on the water, we watched for forecasts with storm fronts, waiting for peak winds and for the wind to shift to a new angle to take each new measurement. We measured the tension on the lines from numerous angles and at varying wind speeds, determined by a calibrated masthead anemometer. Testers then released selected lines, as though they had snapped or chafed through. We populated a spreadsheet, using a simple relationship: Force is proportional to windspeed (with windspeed in knots). We used this to fill in any data gaps, primarily in the higher wind ranges. We also applied our portable test-rig to neighboring boats to confirm reproducibility.

The test location was sheltered from significant wave action; if your harbor is broad and exposed, the math will be different. The bow and stern lines were 5/8-inch nylon double braid, and the spring lines were half-inch nylon three-strand. The slip was exposed forward, flanked by 24-foot boats on either side, and sheltered to some extent by shore astern; a location deep in a marina with similar size neighbors will see less wind.

Test Boat Observations

We know from experience that certain combinations of failures cause little motion. For example, if we need to launch the dinghy from the davits while at dock, we often leave the stern lines off for hours at a time. During testing, we released lines in a controlled way, observed the results, and measured the loads on the remaining lines.

Releasing the stern lines allowed contact with the finger pier, but there was little motion, and the fenders prevented damage. Forces were measured with a load cell over 15-minute periods. The windage on the test boat is very high compared to a typical monohull, particularly from the beam or quarter. The behavior of our 34-foot catamaran probably compares to that of a monohull in the 38- to 40-foot range.

We were surprised that beam winds created smaller loads than fore-aft winds. This is partially due to the damping of the rudder and keel. Boats may quickly surge fore and aft in a bow or quarter wind, but they don’t surge to the side. So while spring lines have poor leverage when asked to support beam loads after the failure of a bow or stern line, the low dynamic loading makes this acceptable. Small chop does not contribute appreciably to beam surging, though large beam waves will change everything.

Changes in wind direction as small as five degrees often made the difference between a boat that will sit quietly to one that jerks around, doubling peak loads. This vulnerability was more pronounced in boats without spring lines, or with spring lines that were too slack.

We observed small loads on spring lines even in beam winds, and significant reductions on bow/stern line loads due to the spring lines presence. Perhaps it was because a truly steady wind is rare, and the spring lines stopped the fore-aft movement. Less motion means lower loads.

The spring line, if continuous, must be cleated at mid-ships in such a way that it is secure if either end breaks. Make the hitch in the normal way; be sure to start and finish outboard and to place a round turn at both the start and the finish.

What about line selection? Our test suggested that it might be beneficial to have less stretch in spring lines than in bow and stern lines. They are longer, so more length is available for stretch. Also, in the event of a line failure, spring lines with less stretch are better able to hold a boat in a safe position. Thus, double-braid springs (less stretch) and three-strand bow and stern lines (more stretch) may be the optimum combination.

Some sailors suggested polyester line for spring lines. We tried it, recorded loads two to four times higher than nylon, and rejected the practice as less practical for a typical slip with four points to which one can tie.

While collecting all of this data, we couldnt help but marvel over the cascading failure that awaits the failure of a single stern line. One boat crashes into the next, overloading lines, until the whole group lays piled together. Weve seen this in the wake of storms, of course, but sturdy spring lines can prevent this.

Data Analysis

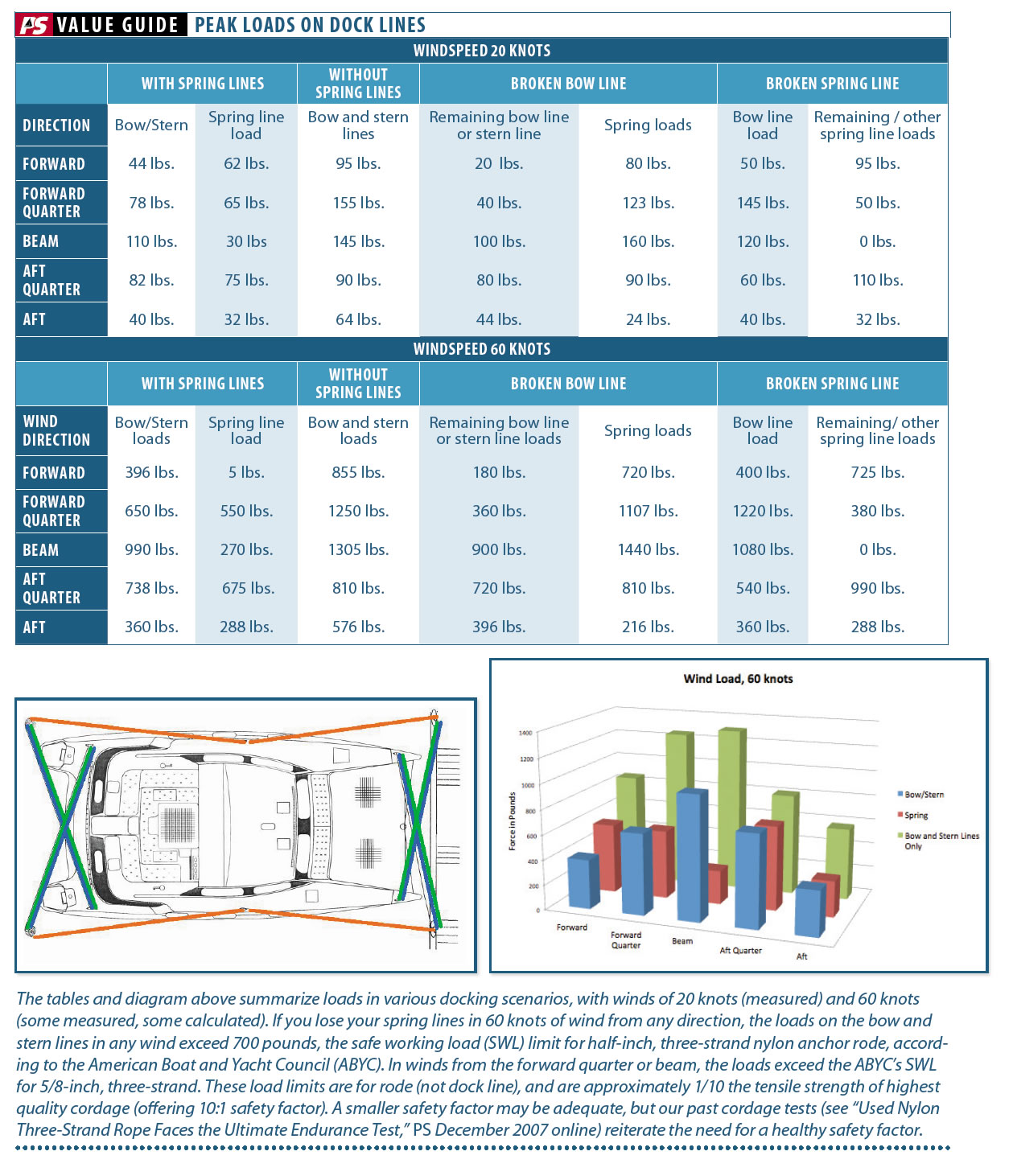

Although the accompanying table Peak Loads on Dock Lines, focuses on peak loads, we did cross-check these with average between readings on different boats, differing line adjustments, and different days. On any given day, the forces could vary greatly from what we recorded. Because we could not test in the strongest winds and could not test to failure, we must rely on extrapolation and knowledge of rope fatigue limits to suggest failures. Forces were extrapolated using the following formula: Force = Constant x Wind2. The short-term fatigue limit of nylon was taken as one-sixth of the breaking strength.

Conclusions

What can we learn from the numbers?

Conventionally sized bow and stern lines, if crossed, should be safe without spring lines up to 60 knots, assuming good chafe protection. But why go without? Spring lines greatly reduce forces and motion, and theoretically extend the safe range to nearly 100 knots, but this is for wind loads only-no waves, no chafe, no loose boat bearing down.

Fore and aft winds created nearly the same peak loads as beam winds. Presumable because the keel provides lateral damping.

Peak loads are reduced 20 to 50 percent by spring lines, although the degree of dampening depends on the wind direction and exact adjustment of the lines.

Spring lines for storm safety must be the same size or one size larger than bow and stern lines, if the full benefit of redundancy is desired. Loads become extreme on the remaining springs when a bow or stern line fails.

This experiments data was extremely variable, and though it shows certain trends, we must be very cautious extrapolating with other boats or locations. Boats vary in windage, weight, and underwater appendages. Marinas vary in protection from wind and wave; slips vary in fit; and cordage varies in elasticity.

Frankly, the data we recorded is a poor guide for every boat, but our exercise does offer a clearer picture of how the lines work together to keep the boat in its slip, and how, with some forethought, we can minimize the damage to our boat using our existing cleats and lines.

Spring lines clearly reduce force and motion, and offer redundancy when you most need it. A full set of spring lines should provide tropical storm level security every day, a great source of confidence when you leave for home. When a hurricane threatens and you have no safer option but to stay put in your marina, add additional lines where prudent, but remember that the starting point for any storm docking arrangement includes well-adjusted bow lines, crossed stern lines, and spring lines that wisely balance stretch, strength, and chafe protection.

The tables and diagram above summarize loads in various docking scenarios, with winds of 20 knots (measured) and 60 knots (some measured, some calculated). If you lose your spring lines in 60 knots of wind from any direction, the loads on the bow and stern lines in any wind exceed 700 pounds, the safe working load (SWL) limit for half-inch, three-strand nylon anchor rode, according to the American Boat and Yacht Council (ABYC). In winds from the forward quarter or beam, the loads exceed the ABYCs SWL for 5/8-inch, three-strand. These load limits are for rode (not dock line), and are approximately 1/10 the tensile strength of highest quality cordage (offering 10:1 safety factor). A smaller safety factor may be adequate, but our past cordage tests (see Used Nylon Three-Strand Rope Faces the Ultimate Endurance Test, PS December 2007 online) reiterate the need for a healthy safety factor.

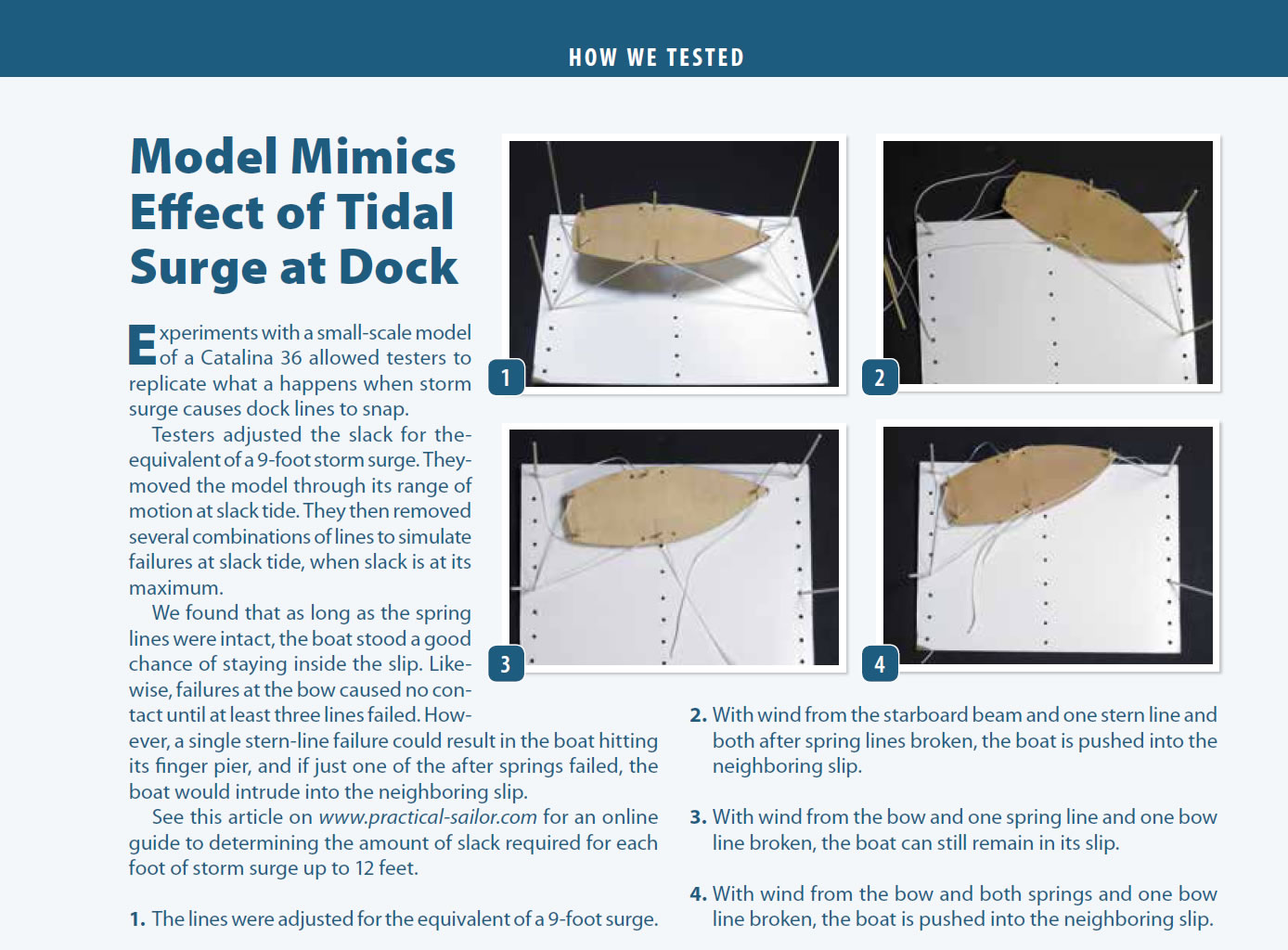

Experiments with a small-scale model of a Catalina 36 allowed testers to replicate what a happens when storm surge causes dock lines to snap.

Testers adjusted the slack for the equivalent of a 9-foot storm surge. They moved the model through its range of motion at slack tide. They then removed several combinations of lines to simulate failures at slack tide, when slack is at its maximum.

We found that as long as the spring lines were intact, the boat stood a good chance of staying inside the slip. Likewise, failures at the bow caused no contact until at least three lines failed. However, a single stern-line failure could result in the boat hitting its finger pier, and if just one of the after springs failed, the boat would intrude into the neighboring slip.

-The lines were adjusted for the equivalent of a 9-foot surge.

-With wind from the starboard beam and one stern line and both after spring lines broken, the boat is pushed into the neighboring slip.

-With wind from the bow and one spring line and one bow line broken, the boat can still remain in its slip.

-With wind from the bow and both springs and one bow line broken, the boat is pushed into the neighboring slip.

Please give the raw data. Thank you.