Spring is here, and that means its time for systems and safety checks. Among the items that should be on your to-do list are checking your seacocks and making sure essential safety gear is on board. For us, that has always included keeping an inventory of soft wood thru-hull plugs for plumbing emergencies, but this year, we decided to also add a few of Forespars new closed-cell foam TruPlugs.

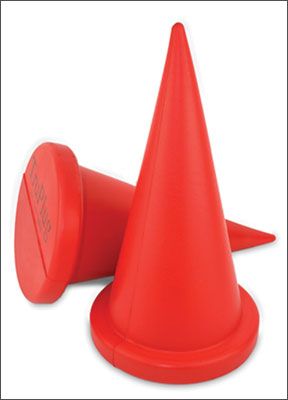

The TruPlug is more versatile than a traditional wood plug. Like the tapered wood plugs, the 9-inch-long, cone-shaped TruPlug can be used to stop or slow leaks at a thru-hull, but it also can be crammed longways into a hull breach or cut to fit varying sizes of busted hoses, broken pipes, or any irregular hole up to 4 inches in diameter.

Invented by a sailor, the TruPlug is manufactured by Artelier Studio of California and distributed by Forespar. It is made of a soft, proprietary foam that allows it to be compressed to fit an irregular opening. Where wood plugs often must be pounded in place by a hammer, the TruPlug can be inserted by hand or using a screwdriver or putty knife. Once its inserted, the cone de-compresses to fill the space, slowing or stopping leaks.

Practical Sailor

One benefit testers noted of the wood plugs over the TruPlug was the fact that the traditional plugs come with drilled holes for attaching them to seacocks via a lanyard so they are readily available in an emergency. It would be easy enough to cut the TruPlug to fit a particular seacock and hang it by a lanyard, but that would negate the benefit of the TruPlugs adaptability to an unexpected leak.

Its price, $20 per plug, is comparable to a similar-sized wood plug. A set of four or five smaller wood plugs (up 1.5 inches in diameter) runs about $15.

In our opinion, the TruPlug is an innovative product, and it would be wise to keep a few on hand for unexpected emergencies. But we still recommend keeping an inventory of various-sized wood plugs, and we plan to continue our practice of hanging a properly sized plug near each thru-hull on our boats.

found the TruPlug easy to cut to size, using scissors and a knife. Cut sections of the plug, where there was no sealer coating, tended to absorb water during testing, but the amount was minimal and would not affect the plugs ability to stem a leak.