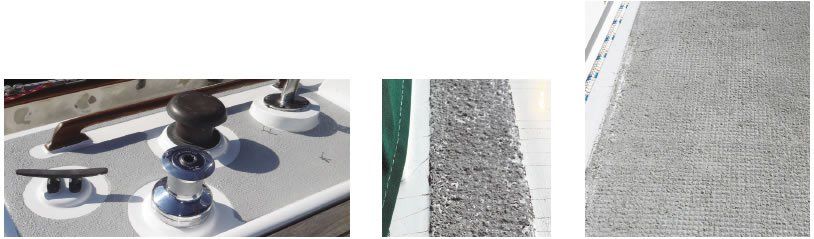

In the January 2012 issue, we evaluated the application ease and traction performance of do-it-yourself nonskid options. A few months prior to the report, a Practical Sailor tester applied the tests Best Choice pick, Durabak, to the coachroof of his Chesapeake Bay-based 1978 Union 36; this served as a real-world test of the coating systems application ease and coating longevity. That field test has reached the five-year mark, so we wanted to offer an update on the coatings long-term performance.

Long-term Performance

Over the years, we’ve had several readers write us with complaints that their Durabak nonskid paint had changed color over time and that the coatings integrity had broken down sooner than expected. Our tester had a similar experience: The paints original, pleasant-gray color weathered to a darker gray that resembled wet concrete, and the grit had begun to wash away after five years; however, the test boats coating still offers acceptable grip action.

We asked Durabak (the paints distributor, www.durabakcompany.com) about the color change and degradation.

The lighter colors may darken or dull somewhat over a period of time due to various environmental factors, explained Durabaks Jake Ickowicz. However, a dramatic color change is highly unusual. … Five years is normally the minimum time in which [Durabak] might begin to wear down, however, many customers do get 10 to 15 years of good use.

In light of our coatings color change and breakdown, Durabak offered to send new product for re-application, as they would for any customer whose coating failed. They instructed our tester to either re-apply a coat of the textured Durabak ($140 / gallon), repaint with the non-textured Durabak ($140 / gallon), or repaint with a urethane (prices vary). This would entail the same level of pre-application prep work as the initial Durabak application.

This echoed the instruction that the company offered to Practical Sailor reader Ernst Niebur, who also keeps his boat in the Chesapeake area and had reported adhesion problems with his DIY Durabak coating after just two years. (See Mailport in the May 2015 issue for details.) According to Niebur, he followed the companys advice, and in 2015, he applied two more coats of the Durabak nonskid, using the exact application steps that the company outlined.

Niebur explained, It failed even faster than the first application. Already early in this summer, I noticed the tell-tale flakes of a failing Durabak coating. Now, the coating comes off in huge patches. … The failure mode is the same as before: While the first coat adheres tenaciously to the original gelcoat, it is the subsequent layers of Durabak that separate from the lower ones. … The second batch of Durabak may have been perfectly fine, but it was applied over a layer that did not allow any bonding.

Bottom line

Given the long-term performance of Durabak aboard our test boat, as well as the field reports we’ve gotten from several readers, we can offer only a Fair rating for Durabak nonskid paints durability at this point in testing. It still maintains an Excellent for ease of application, Good+ for grit uniformity, and Good- for ease of cleaning.

Stay tuned for a full update on the weather-resistance performance of the other nonskid products we reviewed in the January 2012 issue.