The leading cause of death of metal tanks, on land and at sea, is corrosion. Industry standards for fuel tank farms require internal inspections starting at 15 years, and as a licensed API tank inspector, our Tech Editor Drew Frye knows well why these interior inspections are required.

Frye has crawled over and inside uncountable thousands of steel and aluminum tanks. After 15 years of service, hes found that few older tanks have no pitting at all, and serious damage is common. Salt, contaminated bottom water, sludge, galvanic corrosion, and stray currents wreck havoc. Plastic tanks are immune. Although not used in large tanks for reasons of strength and fire safety, molded plastic tanks have become nearly universal among small boats and passenger cars, commanding over 95 percent of the market.

We interviewed manufacturers, reviewed accident studies, mined inspector observations, and combed through boater experiences to determine the advantages of plastic tanks, as well as where the downsides might lie.

We also encourage readers to review our previous report on options for sailors looking to replace their existing tank (see Diesel Fuel Tank Replacement, Practical Sailor May 2007).

Causes of Fuel Tank Failure

Faulty installation is close behind environmental corrosion as a cause of tank failure. Frye has seen tanks collapse or burst because the vent was blocked, forgotten, or plugged. In Delaware he witnessed several million-gallon tanks corrode through 3/8-inch steel plate in months, after a vandal stole the grounding cable that had been safely conducting away a small stray electric current.

Failure to clean tanks on a regular basis is a risk factor. The oxygen or other ion concentration under the deposits can be different from that in the free liquid, creating a galvanic concentration cell. Sulfide reducing bacteria can quickly corrode steel. This is less of a problem with ultra low sulfur fuel, but biodiesel and diesel contaminated with traces of ethanol have increased bio-corrosion risk.

Though not technically a tank problem, chafed fuel lines are a serious risk factor and are a leading cause of fire. Combine this with a chafed power cable nearby and the result is fire.

Frye actually watched a fire like this happen on a truck. The driver had been gone for more than an hour, but he and some coworkers had stayed late to shut the plant down. In the dusk light they noticed a flashing under a truck, followed by flame and a stream of burning diesel running toward a row of parked trucks. Because the fire was out in the open, it was quickly extinguished. The cause was routing both the fuel line and the battery cable through the truck frame in the same bundle.

Ethanol caused the early demise of many fiberglass tanks in the 80s and 90s. Nevertheless, Frye has had fiberglass tanks made from ethanol-rated resins that lasted decades without ill effect. He has inspected hundreds of ethanol-rated E10 fiberglass tanks, some as old as 35 years, and never found a fuel related fault (about 85 percent of in-ground gasoline tanks at service stations are fiberglass). Modern resins are rated for up to E 25 (25 percent ethanol). Check the resin ratings before going down this road.

Causes of Fuel Aging

Something we have long noticed at PS is that gasoline and diesel control samples in our aging and corrosion studies never really age much. Only when the samples include metal samples do they generate gum and discolor. One explanation is refinery stability treatments, but the primary difference is that copper and zinc ions are powerful catalysts for polymerization. Fuel storage systems on land do not experience this type of decay because copper tubing, brass fittings and galvanized pipe are forbidden by code -only steel and aluminum are acceptable.

Low Permeation Hoses

Sometimes it is not so much what has been added, but what is missing that cause tank decay. Fryes last boat had an older plastic tank, and though quite sound and leak-free, the compartment always smelled of gasoline. Fortunately, it was a catamaran, and tank was in a compartment in the bridge deck, allowing the vapors to drain overboard, like a propane locker. Studies by Boat US and the EPA have shown that 5 to 20 percent of the contents of a portable or installed polyethylene tank can vanish over the course of a year, the result of breathing losses and permeation. The remaining fuel is lower in octane, contains fewer of the volatiles so essential for easy starting, and has reduced solvency for gum and varnish control.

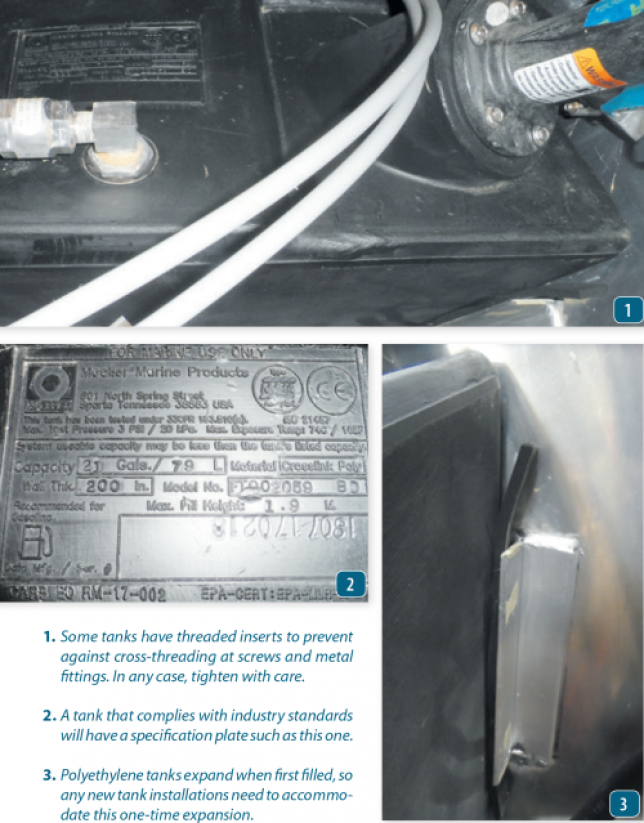

The solution is a tank made of low permeation plastic, improved vent management, and better storage locations. Starting in 2012, EPA required low permeation resins for jerry cans, plastic tanks, and hoses. A plus for the environment, this is achieved by using a two-layer construction (a bonded nylon liner), doping the PE with nano-sized clay particles, or fluorinating the final product in a chamber. Vent filters (see Practical Sailor, January 2013), which reduce water absorption and reduce breathing losses, pay for themselves over a typical 10-year life. Keeping the tank full reduces breathing. Portable tank vents should closed anytime the motor is not running and always overnight. Keep tanks out of the sun; not only does thermal heating increase breathing and pressurize sealed tanks, it rots the plastic over time.

Permeation is a problem for diesel also. Diesel smell has legendary ability to permeate and linger.

The Upsides of plastic

Low Cost. Plastic tanks are considerably less expensive to manufacture, particularly once the tooling costs are paid for. Manufacturers tell us the break point is about 20 units. But lets not equate mass production with lesser quality. There isn’t a yacht or luxury car on the market that doesn’t contain mass-produced parts. Since the human factor (welder) is removed, experience suggests that quality control of molded tanks exceeds that of welded tanks.

Many Stock Sizes. Over time, as more boats use plastic tanks, the range of stock sizes has blossomed. With a little creativity, a near custom fit is likely.

No Corrosion. A US Coast Guard study of the effect of E10 on aluminum tanks concluded that the average life expectancy was only 20 years, with some failures in less than a year.

The Downsides

Limited Baffling. Full baffles, in the sense that metal tanks can use full-high baffles with small holes, are impractical. What you get are molded in ridges, which have proven more than sufficient for small powerboat tanks. It can also be smart to break a single large tank into several smaller tanks. The tank on Fryes last boat had no baffles, was about as wide as it was deep, and it presented no problems.

Fuel aeration is always concern. Gasoline-powered boats can pass a few tiny air bubbles without difficulty; a carburetor is an affective separator and the fuel injection pumps are low pressure. Diesels, on the other hand, vary in the efficiency of air separation. The fuel return can sometimes generate enough fine bubbles to cause trouble when the tank runs low. The cure is probably as simple as avoiding running below 25 percent full in rough conditions.

And when it comes time to clean the tank, you wont miss those baffles one bit. Unfortunately, cleanout openings on plastic tanks are restricted in size for structural reasons, but too-small openings are common on metal tanks too, so nothing new. Without full baffles, a smaller opening can work.

Fire safety. Given the high frequency of corrosion-related leaks and the likelihood that such leaks may cause a fire, anything that reduces leaks is a positive. Even the shore-side fire code (NFPA 30), written for tanks from 275 to>10,000,000 gallons, allows for polymer tanks if corrosion problems makes this advantageous.

Approved gasoline tanks must pass the same burn test used for steel tanks (1200 F for 2 minutes without leaking). They are made of crosslinked high density polyethylene, which is a thermoset plastic and does not melt in the way that the polyethylene used in a milk bottle does. Its not as easy to burn through a tank below the liquid level as you might think. (Ever watch the boil-water-in-a-paper-cup experiment?) It is even legal to weld on large (million gallon) steel gasoline tanks as long as you are three feet below the liquid level; the gasoline on the reverse side cools the steel and there are no vapors present. Hard to believe, but Frye has watched the work in progress (note-the tanks covered by the relevant code, API 653,must be at least 3/16-inch thick). It is basically impossible to burn through a poly tank below the diesel level in any fire a fiberglass boat can survive.

Poor UV Resistance. Twenty to thirty years of sun exposure can do a number on plastic, but this is easily avoided by either covering or painting the tank. Additionally, by that time metal tanks are at high risk of corrosion. Even stainless can crack.

Hydrocarbon Expansion. When a polyethylene tank is first exposed to hydrocarbons, it grows about 2 percent in all dimensions. Any installation must allow for this one-time expansion.

Top Openings at Center. Without baffles, openings at the end are vulnerable to liquid slapping up. This is a known problem with unbaffled road tankers. Metal tanks generally contain sufficient baffles to reduce this factor … but not always. Poor opening placement is one of the more common causes of leaks across all types of tanks.

Chafe. All contact points should be padded with rubber or other non-abrasive material. On the plus side, plastic tanks do not suffer if bilgewater or condensation become trapped against the tank.

Custom Sizes. While possible, custom molding is considerably more expensive than metal tank fabrication if less than about 20 units are needed. Custom plastic tank builders, who weld potable water and blackwater tanks from sheet, wont touch fuels.

Conclusions

Frye is not implying polyethylene tanks are perfect. The relevant question is Are they better? He has seen too many aluminum and steel tanks fail to want either. Same with stainless. Monel is pricey but pointless to argue against if well-made.

Perhaps new, low-perm crosslinked plastics will impact the market as Dyneema has for standing rigging. It might be the next new thing. Or not.