Fiddle rails are pieces of wood to keep the dishes on the table. A fiddler’s green is a sailor’s paradise of dance halls, bars and worse. A fiddle head is either a fern frond alleged by those with no taste buds to be edible or an end of timber carved like a violin head. And it’s the shape of the common violin body that supplied the name for what sailors call a fiddle block.

Known to purists as a long-tackle block, the fiddle block has two sheaves of different sizes placed flat in the same plane. It’s not as compact as a double block, which has the sheaves side-by-side on a single axle. Either one can multiply purchase power by three—or four with a becket. Another fiddle or double is needed on the other end, the one that moves.

Double blocks can chafe line (even when equipped with swivels), but fiddle blocks behave beautifully. They see sterling duty for boom vangs, mainsheet systems, backstay adjusters and downhauls.

They can be used, too, for swinging supplies aboard, bending ship timbers or retrieving the MOB, as the hapless man overboard has become known. (As a matter of fact, the MOB now is often called the POB or COB….and could as well be called the LOB, SOB or BILOB; for the latter three acronyms, substitute “lady,” “skipper” or “brother-in-law”.)

Fiddle blocks usually are an integral part of what are called “fiddle,” “chain” or “cascading” systems… most of which can be single-speed or double-speed. The increasingly popular double-speed arrangements retrieve or ease line at two different rates, using one or two tails. Mind you don’t lose either tail.

Because fiddle blocks come in many sizes and, in many applications, are rigged with cam cleats, Practical Sailor gathered up for this review several dozen fiddle blocks—almost all fitted with cams, as well as beckets and swivel heads.

The Collection

Included in this collection are blocks from the big-name manufacturers known to most sailors. In alphabetical order, they are Barton (British), Frederiksen (Danish), Garhauer (U.S.), Harken (U.S.), Lewmar (British), Ronstan (Australian), Schaefer (U.S.) and Wichard (French).

Except for Barton and Wichard, all of these companies offer an amazing array of blocks of all kinds. Barton, a once-powerful English firm, has mounted a vigorous re-entry into the yachting market but does not yet offer as many choices. Wichard, noted for its stainless steel shackles and snap hooks, recently started offering a fair range of blocks.

The premium end of the market is still dominated by Harken Yacht Equipment. Like most of Harken’s extensive line of blocks, these fiddle blocks are loaded with bearings. Harken likes its position as the maker of the most friction-free marine hardware—if you can afford it.

Nipping at Harken’s polished heels, and also seeming to care not a whit about price, is Frederiksen, whose line was introduced in the United States in 1994. Placed side-by-side, for examination or hard usage, both Harken and Frederiksen represent the ultimate in smooth, easy-running fiddle blocks.

Occupying the middle ground are the giant Lewmar, Ronstan and the very solid, reliable Schaefer. Not as precision made nor quite as free-running as Harken and Frederiksen, the fiddle blocks from these three companies offer excellent quality at reasonable prices.

The maverick is Garhauer, a California company that in its fiddle blocks couples great strength with amazingly low cost.

The Strength Question

It’s important these days to pay close attention to blocks. Blocks and other hardware once were stronger than any line with which they were rove. In other words, if subjected to extreme loads, the line broke long before the hardware. That is no longer true.

With expensive lines like New England Ropes’ Z-Tech PBO Zylon or Sampson’s Spectron 12 Plus, what looks like pretty but ordinary half-inch line can have a breaking strength, respectively, of 25,000 or 36,250 pounds. Even the now-common lines such as New England’s Sta-Set and Yale’s Yacht Braid can have, in the half-inch size that’s easy on hands, breaking strengths of 3 or 4 tons.

For such half-inch lines, one might use 75 mm Harken Air Blocks, Series 8 or 9 Schaefer blocks or 80 mm Lewmar racing blocks. For strength, all of them would be seriously outmatched. They have maximum working loads, respectively, of 5,000 pounds, 2,750 pounds and 2,200 pounds.

Overload these combinations and what will break is the block.

When fitted with cams, as with this collection, ultimate strength becomes somewhat academic. The strength needed by a crew to secure and release a line from the cams becomes the limiting factor…unless the pressure, for instance, of the mainsheet or vang is eased by a quick luff.

However, because fiddle blocks often are led to winches, strength is a big issue…especially considering the shock loads often imposed on blocks by running rigging.

Testing the strength of these cheek blocks is complicated. The breaking strength might be easy to detect, but the point where they begin to distort permanently (the safe working load) would not only be difficult, it might be subjective. The failure can come through slight bending, which can accelerate wear, or the fracture of ball bearings (in those blocks so equipped). To detect initial damage, blocks with solid bearings would require repeated dismantling and careful measurements. With blocks with bearings, a grinding noise from shattered bearings usually signals failure. Blocks with ball bearings generally are not as strong as those with solid bearings. In fact, Schaefer states in its catalog, “Ball bearing blocks are not designed to withstand long-term static loads.”

In lieu of bench testing, the table above displays each manufacturer’s claims of both safe working loads (sometimes stated as maximum working load) and breaking strengths. The figures are for fiddle blocks selected primarily for a 3/8″ maximum line size but also for their sheave diameters. It was the only way that anything resembling a matching set could be lined up for comparison.

The chart above also shows suggested retail prices for these particular blocks.

The Evaluation

Working alphabetically means beginning with the innovative Barton line.

Barton fiddle blocks range in size for line from 5/16″ to 9/16″ with safe working loads (which Barton calculates as half the breaking strength) from 815 to 2,750 lbs. All are available with a plain brass bearing or Barton’s new twin-race Delrin balls. The cheeks are glass-impregnated nylon, but the plastic sheave loads are carried by ss straps mounted inside the cheeks.

The Kevlar cams also are new to Barton. Barton calls them “K” cams. In the smallest sizes, the cams are mounted on plastic arms, with excellent (about 65°) adjustibility. On larger models the cam platform is stainless, with a skimpy adjustment range (about 25°). Barton’s “Variloc” swivels allow the shackle to be fixed at 30° increments or left to swivel.

Frederiksen blocks, for big or small boats, are expensive because the Norwegian company goes for a careful balance between high strength and low weight, using combinations of aluminum or stainless cheeks, aluminum or Delrin sheaves and Delrin or Torlon needle and ball bearings.

Frederiksen’s standard fiddle blocks are available only in the Series 60, 75 and 100 racing blocks. They have three-way heads and handsome black-anodized aluminum cheeks (no straps) and sheaves with two or three rows of Delrin bearings. Frederiksen uses Holt-Allen cam cleats (with roller bearings) mounted on stainless arms with 60° of adjustment.

Even further up the save-weight-at-any-cost line, a big titanium Frederiksen fiddle block (breaking strength: 24,696 pounds) with both needle and ball bearings (but no becket or cam), will cost you…if you really want to know, call and we’ll whisper “about $1,500” in your ear.

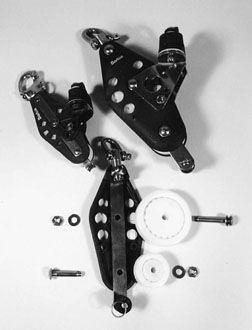

Garhauer’s fiddle blocks are, like most Garhauer equipment, powerhouse stuff at low prices. Although the California company makes some big titanium blocks, the standard versions come in two basic styles— those with stainless cheeks and stainless load straps, and the now-more-familiar “hollow” blocks, whose cheeks serve as load straps. The latter are lighter—but equally strong. Garhauer uses Ronstan and Harken cam cleats.

Garhauer makes three sizes of fiddle blocks, with safe working loads from 1,150 to 2,450 pounds. Equipped with beckets, swivels and either Ronstan or Harken cam cleats (the cam bases are not adjustable), the fiddle blocks range in price from $41.80 to $59.40. The company does not specify breaking strengths. It just guarantees everything. However, its catalog states that “if used in exceptionally high load areas, we recommend switching to the next higher size.”

Harken offers perhaps the most fiddle blocks—ranging from the tiny 22 mm version with a simple V-cleat to the big 76 mm “double ratchet fiddle cam” used in its widely known two-speed mainsheet systems (see photos). Like Frederiksen, Harken uses combinations of high-strength plastic, black-anodized aluminum and stainless steel to appeal to those who like high-tech equipment.

Always innovative, Harken introduced plastic ball bearings in 1967 and followed that with fitted ball races, carbon-filled balls, adjustable shackles and removable beckets (an important consideration for those who do the splicing).

On its fiddle blocks, Harken uses its own cams, which have an adjustable range of 60° for the smaller models to about 45° for the large ones. The cams are uniquely reversible for up or down belaying.

Like Harken, Lewmar offers what it calls “hard-working, well-proven fiddle blocks” with, in the small sizes, either plain plastic sheaves and stainless straps, or, in the larger sizes, with gray-anodized aluminum cheeks and aluminum sheaves riding on Delrin or Torlon ball bearings.

The standard blocks (called Ocean blocks) are not especially handsome, but the lightweight “hollow” blocks (called Racing blocks) vie with Fredricksen or Harken in appearance.

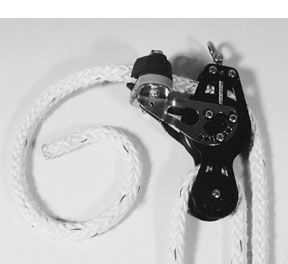

All Lewmar fiddle blocks are available with adjustable heads. Some are equipped with Ronstan cams, others have German-made Servo cams. The standard fiddle blocks’ cam platform is fixed (see photo), but the Racing blocks have a circular mount secured with three Phillips head bolts that permits more adjustment than any other make. The becket on the Ocean fiddles is easily removable; an Allen wrench is needed to remove the becket on the Racing blocks.

Ronstan has worked hard to incorporate some interesting and unusual features in its fiddle blocks—which range from a tiny stainless V-jam to medium-sized ball bearing models to big tough fiddles with unusual black-chromed stainless cheeks.

Indicative of Ronstan’s creativity is its Series 50 fiddle block (see photo), which was introduced in January of 1999. Made far more compact and much stronger than comparable fiddles, this block has a one-piece stainless strap—up one side, over the top and down the other side. It has the highest advertised breaking strength of any of the fiddle blocks in this review.

Other clever features include a becket in keyhole slots, a head that is adjustable with a sliding lock operated with a thumbnail (no tools, no screws) and a 70° range on the cam lock platform. The fiddle blocks are fitted with the excellent Ronstan cams.

The ever-reliable Schaefer fiddle blocks cover the gamut—from the best little stainless V-jammer to a big stainless giant that rivals Garhauer for both strength (SWL: 2,750 lbs.) and weight (2 lbs., 1 oz.). That largest fiddle block has a special bearing made of Nomex, glass fiber and Teflon (for lubrication). Schaefer says the bearing, rated at 35,000 psi, is “immune to load-induced distortion” and requires no maintenance. The side-load Delrin ball bearings should, however, be flushed often with freshwater.

In between are models with black-anodized or stainless cheeks, available with either ball bearings or the stronger Delrin-on-stainless axles.

Schaefer’s fiddle blocks are equipped with stainless cam cleats, some on adjustable platforms with about a 45° range, some fixed.

Wichard, relatively new in the block business, offers three sizes of fiddle blocks. Each comes in two versions, with plain or ball bearings. Unlike other bearings, the Wichard patented system places the ball in races in the cheek. When the load overwhelms the bearings, the load shifts to the axle. Wichard lists the same SWL and breaking strength for both versions

The cam models are equipped with Servo cams; the cam platform, which has a limited adjustment range, is not well designed.

The Bottom Line

All of these fiddle blocks will give good service. Some are a bit stronger, some have clever features, some are a little smoother running and some might be said to be better looking.

It’s doubtful that the Frederiksen fiddle blocks will appeal to anyone but serious racing sailors or those willing to pay outlandish prices for very high-tech equipment.

Barton’s new line of blocks is well done. Ronstan’s innovations are thoughtful and make for strong fiddle blocks. Wichard’s patented ball bearing system makes very good sense.

Harken is for those who prefer smooth operation over strength. Schaefer’s extensive line probably encompasses the best compromise.

If cosmetics are a factor, Lewmar’s standard fiddle blocks are least appealing; its ball-bearing blocks are fine. The Lewmar and Garhauer fiddle blocks are the Best Buys.

Also With This Article

Click here to view Value Guide: Fiddle Blocks.

Contacts- Barton, Imtra, 30 Samuel Barnet Blvd., New Bedford, MA 02745, 508/995-7000, fax 508/998-5359. Frederiksen, Maritime Supply, 12 Plains Rd., Essex, CT 06426, 860.767-0468, fax 860/767-6560. Garhauer, 1082 W. Ninth St., Upland, CA 91786, 909/985-9993. Harken, 1251 E. Wisconsin, Pewaukee, WI 53072, 262/691-3320, fax 262/691-3008. Lewmar, 351 New Whitfield, Guilford, CT 06437, 203/458-6200, fax 203/453-5669. Ronstan, 7600 Bryan Dairy Rd., Largo, FL 33777, 727/545-1911. Schaefer,158 Duchaine, New Bedford, MA 508/995-9511. Wichard, 47 High Point Ave., Portsmouth, RI 02871, 800/852-7084.