The nemesis of inline strainers and pump inlet screens is limited area. High flow and the resulting pressure drop forces the debris deep into the holes, causing stapling and making cleaning difficult. Limited area reduces flow and increases cleaning frequency.

What if a strainer is built around the sump pump, allowing much greater area, so large that the pressure drop is reduced to no more than gravity? Instead of driving the trash into the mesh, debris often just falls off between cycles. If not, it is easily brushed off, because it is not driven into the holes.

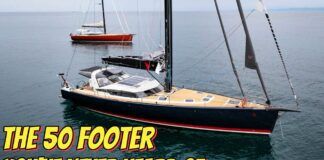

The ultimate in sump pump protection. The box frame can be wood, metal angle, or fiberglass. The sides are ¼-inch perforated metal. The top can be left open. About 8 inches deep and 1-2 feet on a side.

Minimum size is about 5 square inches per gallons per minute (GPM) flow, or about 150 times the pipe flow area, although twice this is better. This is more than 5-10 times the minimum recommend pipe strainer area.

Sure, keeping the bilge clean is the best practice, but even well maintained boats accumulate some hair and splinters, and in the event of serious flooding or a knock-down, all matter of paper scraps can wash down from nooks and crannies you didn’t know you had.

- A variation on the strum box, this DIY strainer is simple to build, clog-proof (it will overflow down the drain when it clogs) and can provide a lot of surface area.

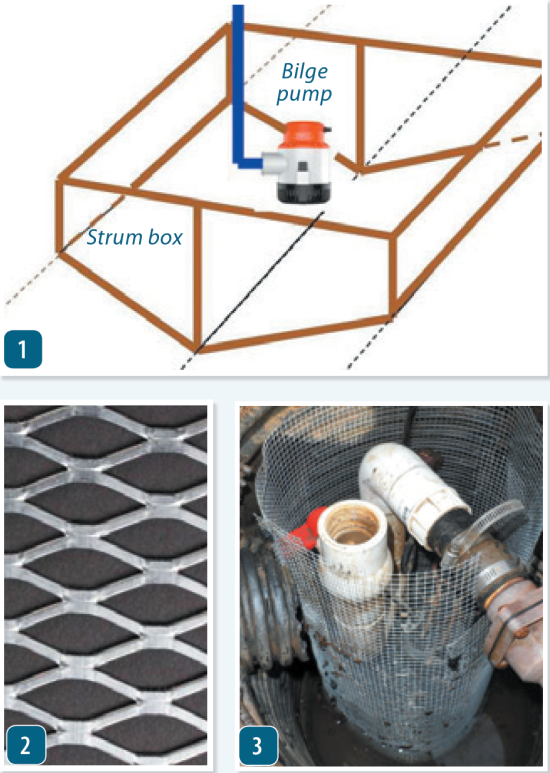

- Do NOT use expanded metal as shown here. Use perforated metal for the sides.

- This hardware cloth strum box keeps sticks out of tech editor Drew Frye’s backyard sump pump.