Like most sailors, we purchased our meter to investigate the condition of a cored boat, and specifically to learn more about how far the moisture had travelled from a few fasteners where the bedding had failed. Like a glorified stud finder, the reading is based on capacitance and not direct measurement of water content. Thus, any belief that readings will be accurate is wishful thinking.

Moisture meters don’t read frozen water. Evean hot vs. cold can change readings as much as 5%. Whenever possible, we recommend calibrating with a section of material similar to the deck and core in question.

Perhaps the biggest variable can be reinforcements and changes in layup.Always compare both sides of the boat for symmetry. Samples of never-been-outside laminate from the shop sample stack read 2-16% moisture, depending on thickness, layup, and materials used.

Testing the hull on boats just hauled from the water is highly unreliable and prone to produce false readings. Let it dry for a few weeks. As for the cabin top, recent rain on gel coat has little effect so long as it has dried. Voids and dry core will block readings.

Areas that are wet but that have also delaminated can read relatively dry. Fairing material reads higher than laminate or core. A rotted core that is now dry will read as dry, so you still have to tap and press on the hull and deck to find delamination.

Below 20% moisture rot does not grow. At 30-50%, the core may not feel very wet, but rot will flourish. In solid laminate, high moisture readings deserve further investigation, but aren’t necessarily a death knell.

See review of moisture meters, “Moisture Meters, Can You Trust Them?” Practical Sailor, September 2000.

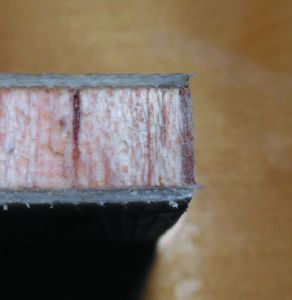

- Dry fibers cut cleanly.

- Readings on this panel increased from 8 to 30 percent over several days

- This panel is no longer wet, but torn fibers indicate past exposure.