Back in 1992, a friend of ours competed in the OSTAR (Observer Single-handed Transatlantic Race). Onboard electrical demands, especially from electronics, had recently grown, and he needed a charging source other than the engine. Marine wind generators were still unproven and solar panels were prohibitively expensive.

A group of us got together and bought for him a towed water-powered generator for charging his batteries. He came back with good stories of how much electricity it produced-but alas, he lost the boat and generator 500 miles from the finish, so we never got a chance to try it ourselves.

The past decade has brought only greater demand for electrical power. That demand has made wind-powered generators commonplace and solar panel technology far less costly. In addition to the engine’s alternator, these are the most common charging sources for a boat at anchor or underway. However, we rarely hear anything about towed water-powered generators. Always on the prowl for alternative energy sources, we decided to try for ourselves a towed generator on a cruise from the US East Coast to Bermuda and back last summer.

How It Works

The technology behind the towed generator is simple to understand. Its principle is very similar to the old Walker Log. As you sail, you tow behind the boat a spinning propeller on a long line that resists twisting. On the boat end of the line is a generator. As the boat moves through the water, the propeller spins, and the twist-resistant line transfers that spinning directly to the generator, which generates electricity. The faster the boat moves through the water, the more electricity is generated.

It’s worth remembering that it’s the movement of the boat through the water that turns the spinner, not the boat’s speed over the bottom. If a boat were anchored in a strong enough current with the towed generator behind, it could generate power. In this way, homesteaders living “off the grid” can make use of water-powered generators if they live next to a fast-moving stream.

Generator Basics

A generator consists of a rotating armature inside of a magnetic field. The armature contains wire windings connected to a mechanical commutator on its rotating shaft. The magnetic field surrounds the armature and the field is generally produced from permanent magnets mounted on the inside of the generator housing. As the armature rotates, the wire windings intersect the magnetic field. As the winding moves through the field, the mechanical energy of rotation gets converted to electrical energy. The generated AC voltage goes through two brushes “riding” on the commutator, which mechanically converts the generated AC voltage to DC.

The generator’s voltage output is proportional to the number of armature windings and the armature’s rotational speed. Since the towed generator can’t change its armature windings, the voltage output is proportional to the speed of the spinner through the water.

Two important parameters for generators are the electrical resistance of the windings and the number of RPM it takes to produce one volt in an open circuit (i.e. a no-load condition). The lower the resistance, the more current produced for each RPM of the armature. Some typical generator values are an armature resistance of 1.24 ohms and voltage constant of 26.5 RPM/volt. An example will help here:

If one wants to generate 5A at 12V, one needs to generate an open-circuit voltage of: 12V + (5A x 1.24) = 18.2V. The required revolution speed of the armature is: 18.2V x 26.5 RPM/V = 482.3 RPM.

This example shows that one can increase the generator’s power output by either spinning it faster or finding a generator with a lower armature resistance.

Real-World Use

Our goal on the Bermuda trip was to evaluate towed-generator technology for supplemental battery charging, not to evaluate all the different available towed generators. We chose the Ferris Waterpower 200 ($819) from Hamilton Ferris Co. as a representative offering. Other towed generator products include the Ampair Aquair 100 from Jack Rabbit Marine, the Redwing from Downwind Marine, and the LVM AquaGen.

We also brought along the Hamilton Ferris WP-200 R/S conversion kit for ($509) for mating the generator to a wind-powered propeller blade once we got to Bermuda. More on that later.

The Waterpower 200 includes a permanent magnet generator, a spinner, torque line, retrieval funnel, gimbal mount, deck connectors, cable, a Wind/Water Power Generator panel, and a diode/fuse box. The generator itself measures 4″D x 8″L, including the armature shaft. The generator mounts on the taffrail in a gimbal bracket. The bracket fits into a white nylon donut yawing movement. The 6″ x 3.5″ panel has an ammeter, a charging light, and a momentary brake switch.

The installation consists of mounting the gimbaled bracket, mounting the panel and the diode/fuse box, wiring them together with the supplied cable, and then wiring the generator into your battery system. For the purpose of our testing, and not wanting to punch too many holes in the boat, we mounted the panel and the diode/fuse box inside a cardboard box in the navigation area. We then wired this system into the boat’s main electrical panel. We were able to monitor the generator’s performance with the panel’s ammeter together with our boat’s Link 2000R.

The spinner is a 3-foot long stainless rod with a propeller on one end and a threaded receptacle on the other end. The standard prop for boatspeeds up to around 6.5 knots is a Lexan 8″ prop with 5″ pitch. Faster boats may need to change to a prop with greater pitch to slow down the spinner through the water.

The spinner rod can accommodate up to three cylindrical brass weights for keeping the spinner from rising to the water’s surface. Before purchasing any such system, check with the manufacturer for the correct setup for your boat’s size and speed.

The torque line connects the spinner to the generator. This 69′ 11mm nylon line is a very tightly woven braid. Its design is such that it acts as a flexible rod, transmitting each spinner rotation to a rotation of the generator’s armature. Each end of the torque line has a brass threaded screw firmly attached. The screw threads mate with threaded receptacles on the spinner and the generator. You must use a wrench to connect and disconnect these parts.

Deployment is very simple. First, fit the gimbal mount and generator into the white donut and tighten the restraining thumbscrew. Tie the safety line from the generator to a cleat, stanchion, or other fixed part of your boat. Assuming that the torque line was previously installed, start feeding out the torque line from the generator end while keeping the spinner onboard. Make sure that the torque line has no knots in it. Then, drop the spinner over the side. When the boat sails to the end of the torque line, the line will stiffen, and the spinner will start spinning, thereby turning the generator’s armature. The whole deployment process took us about 30 seconds.

Spinner retrieval is a little more complicated. The manufacturer’s recommended procedure is to deploy a retrieval device that consists of a large plastic funnel with the spout removed and a split up the funnel’s side. The idea is to put the split funnel over the rotating torque line with the large opening facing the spinner; then, when you want to retrieve the spinner, you “launch” the funnel down the torque line. When the funnel makes it to the spinner, it shields the spinner from water flow and stops its spinning. At that point it becomes easier to haul in the torque line with the spinner at the end. (Easier, but not easy.)

Water Generator Performance

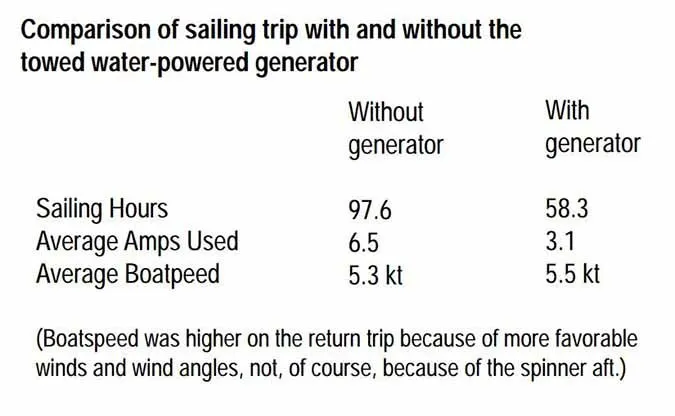

On the trip from Cape Fear, NC to Bermuda, we tracked our electricity usage for the trip. For 98 hours of sailing, we averaged a power usage of 6.5 amps. Our main power users were the autopilot, the refrigeration unit, and navigation lights. The power usage agreed with our historical usage from previous years. On the return trip from Bermuda to Portsmouth, RI, we towed the Ferris Waterpower 200 for 58 hours of sailing time. During this trip, our average power usage was 3.1 amps. The boat’s average speed during both trips was approximately the same.

We attribute the reduction in amps used to the power generated by the towed generator. We were able to monitor the generator’s current output with the ammeter on the Ferris panel and the Link 2000R.

From this test, the towed generator supplied 52% of our energy needs.

The most common question asked by sailors regarding towed generators is, “What’s the effect on boatspeed?” It was difficult for us to determine a quantitative response, but we did try to answer it with a couple of experiments. The first experiment consisted of recording the boatspeed for one minute before dropping the torque line and spinner over the side. After the generator started spinning, we again measured boatspeed for one minute. At 5 knots of boatspeed through the water, we could only measure a drop in speed of about 0.1 knot. We repeated this test twice and got the same result. The second test involved turning on the brake switch on the Ferris panel, thereby stopping the spinner’s rotation. There was no perceptible change in boatspeed with this test.

The amps produced by the Ferris Waterpower 200 on our graph are approximately 55% lower than the graph in the Ferris Power Products catalog. We discussed this discrepancy with Hamilton Ferris, who told us that the graph in the brochure is the current going into a 50% discharged battery. If the battery is less than 50% discharged, then the current output will be lower. This information agrees with our data-our battery usage for the test went from 100% charged to 58% charged.

The Ferris Waterpower 200 was very quiet while being towed through the water. There was a little whirring noise, but it didn’t interfere with cockpit naps. As the torque line streamed from behind the boat, it “walked” to port. The instructions say to mount the generator on the port side of the taffrail so as not to tangle towed fishing lines. We did not try fishing while towing the spinner.

Retrieving the torque line and spinner was much different than deploying it. The steps involve sliding the funnel down the torque line to shield the prop, pulling in the line from the generator end, and then retrieving the spinner from the water. The crew had a good laugh watching us wrangle in the spinner and line!

The funnel has a split up the side with three lacing lines that one ties together to keep the funnel secured around the torque line. All the time that one is tying the laces, the torque line is spinning very close to the fingers, and the line yaws as the boat yaws. It’s a frustrating business. A Velcro-type fastening system, requiring less manipulation near the spinning line, would be a big improvement.

Once the funnel is laced, it gets launched down the torque line. The first time we did this, the funnel sat about three feet behind the boat, in the air, riding on the torque line. Eventually, a few seas touched the funnel, which sent it down the torque line closer to the water’s surface. Once the funnel hit the water, it quickly covered the propeller, stopping its rotation. It would be nice if there were some way to force the funnel to reach the water’s surface instead of having to rely on patience.

Retrieving the spinner, funnel, and torque line at 6 knots was a challenge requiring some strength. The slowest speed we tried retrieving it at was 1.6 knots, which wasn’t very difficult. The real issue was how to handle the stiff torque line once on deck. The first time, we tried coiling the line in a single loop, which caused twists and kinks in the line the next time we launched it. The next time we coiled the line in a figure-eight. This coiling technique was better, but it was difficult to get the line to lie down neatly and stay in place. However, deploying, from the figure-eight was easier with less kinks. We secured the coil with a piece of shock cord to a nearby stanchion. We tried once to retrieve the spinner without the funnel at a slow speed. Twists galore!

Another storage problem was that generator, torque line, and spinner have to be connected together as a single unit with hand tools. It would be more convenient if they could be easily separated with a quick, tool-free disconnect system. As it was, the assembly covered a large part of our lazarette area.

We were also careful about bending the line sharply at each end because of the hard attachment of the line to the brass fittings without strain reliefs. We did notice some fraying at each brass/rope interface after our tests. Hamilton Ferris said that this wear was normal.

As for other concerns about the line, Ferris doesn’t recommend any special precautions with regard to protection from UV light. However, the line will not “forget” any hockles that it may sustain.

Wind Power, Too

Most towed generator manufacturers sell conversion kits for using the same generator as a wind-powered generator while at anchor. The idea has appeal, so we decided to try the Ferris Waterpower 200 to convert wind power into electricity while at anchor in Bermuda.

The WP-200 R/S conversion kit includes, according to the Ferris Power Products catalog, the “wind blade [propeller] and hub, rigging mount frame, wind vane and stainless steel hoisting cable set.”

The kit is a big thing to stow. The prop is 5′ long, and the rigging mount frame just slightly shorter. For the trip to Bermuda, we lashed these two items to the mast section in the cabin, to keep them out of our way. The prop is made from wood with a white coating. It’s light and somewhat fragile.

The first time we converted the water-powered generator to wind-power, it took us about two hours. Some items made the conversion process smoother, including the fact that all bolts were 7/16″ and all set screws were 1/8″. However, some things would have made the conversion go faster:

Labels or stamps on the metal pieces indicating orientation of up or down, especially on the rigging mount frame and the wind vane frame.

The 1-1/4″ bolts in the rigging mount frame that the generator support bracket attaches to are too short. We had to compress the frame to get the bolts in.

Instructions for removing the gimbal frame from the generator.

Make the rigging mount frame one inch longer than the prop, so that the frame’s length can protect the prop from hitting things and getting damaged.

Metal clips on the rigging mount frame for attaching the generator’s wire, instead of requiring disposable nylon wire ties.

The wind-powered system is designed to be hoisted in the fore-triangle. The upper hoisting cable (pendant) from the rigging mount frame connects to a forestay. A halyard hoists the wind-powered generator up the stay, high enough to not decapitate anyone. The two lower pendants attach to stanchion bases or other tie-down points on the port and starboard side of the boat. The wind vane has a line tied to the mast to restrict twisting of the generator. The electrical cable from the generator drapes down and away from the spinning propeller. Note: we would like to see a hole in the hoisting cable shackle pin so that it can be moused with seizing wire.

We quickly realized that we had a problem when we went to raise the wind-powered generator-our roller furled headsail covered the forestay! So we had to create a new temporary stay for the upper hoisting pendant to ride. We used the main halyard, tying the bitter end to a fitting on the stemhead and extending the headboard shackle end with another piece of line so that we could take a couple of turns on a mast winch and set the halyard up tight. Then we attached a snatch block to the hoisting cable and used its sheave to ride up and down our new “stay.” This system worked fine.

Once we converted the generator over to wind power, it still took us 20 minutes to hoist the wind-powered generator. We were doing it solo, and one challenge was how to keep the blade from spinning until it was raised to the proper height. There was no one else around to hold the momentary brake switch, so we tied a loose clove hitch around the bottom blade of the prop and the rigging mount frame, with the bitter end at deck level. After raising it to the right height, a shake of the line caused the knot to collapse and fall to the deck.

This rigging-suspended generator requires that the boat be on an anchor and able to swing (i.e., point) into the wind. If there’s a strong current counter to the wind, you may spend a lot of time adjusting lines to keep the generator facing the wind.

The propeller does not have a governor. This means that if the wind starts honking, you may be spinning the blade too fast. One way to “dump” the wind is to move the wind vane line purposely so that the generator isn’t pointed directly into the wind.

Getting the wind-powered generator down also took some time. The first time we tried to stop the blade with the brake switch. It did stop, but since it’s a momentary switch, by the time we ran over to the halyard, the prop had started spinning again.

We found that throwing a light line into the spinning blade would tangle it up and stop the blade.

If we were going to use the wind-powered generator for cruising, we would replace the momentary switch with a normal toggle switch. Another idea to stop the propeller is to tie off the wind vane 90 to the wind direction.

It turned out that trying to measure how well the wind-powered conversion worked was much more difficult than with the towed-water generator. Electrical usage varied with the number of times the icebox was raided, the Lectra/San ran, music blared, and propane cutoff switch left on. (Kids!) We collected data for 247 hours without the wind-powered generator and 154 hours with the wind-powered generator. Looking at the raw data, the generator supplied, on average, 1.3 amps, or about 35% of our needs at anchor. However, we also had a tropical storm pass nearby. If we eliminate the storm time, the generator supplied only 0.4 amps, or 12% of our needs. The average wind speed during the tests was approximately 7 knots.

We get a more telling indication of how well the wind-powered generator worked for us wheb we look at wind speed versus current output. With the wind speed below 10 knots, there was hardly any power generated. Our graph is about 65% lower than the graph on page 12 in the Ferris Power Products catalog. This time, though, our batteries were more discharged-the batteries varied from 76% charged to 32% charged. We can’t explain the discrepancy in the graphs, nor could Ferris.

Conclusions

For the amount of storage space it demands, the hassle factor putting it up and down, and the small amount of electricity it generates, we would be reluctant to recommend the wind-power conversion kit. If you require power generation at anchor, a dedicated wind generator, optimized to perform its one intended function, will be a better bet.

The Ferris generator itself, however, in the guise of the Waterpower 200, does generate electricity-quietly, safely, and with few hassles-and we can easily recommend it as an electricity generating source for any offshore cruising boat. We also believe that with a little optimization for each particular boat, one can increase the generator’s efficiency by choosing the most suitable prop for the boat’s typical speed and battery discharge level. We would like to see a few changes that may or may not be specific to the Ferris product, including an ammeter with a more expanded scale at the low end, easier connectors (tool-free) for the torque line, a toggle brake switch, and an improved retrieval funnel.

These systems are not maintenance-free. Brushes and bearings do wear out and need replacing after hundreds of hours of use. “We recommend a check of bearings every 6 months,” says Hamilton Ferris. “No one ever does it. When new, they are 5/8″. When ready for replacement they are half that. We offer a Brush & Bearing Kit for $44, plus shipping.”

Contacts

Downwind Marine, 619/224-2733, www.downwindmarine.com.

Hamilton Ferris Co., 508/881-4602, www.hamiltonferris.com.

Jack Rabbit Marine, 203/961-8133, www.jackrabbitmarine.com.

LVM Ltd., 011 44 0 1462 733 336, www.lvm-ltd.com.