The editors at Practical Sailorget a few reports of broken anchors each year. Typically, these are failed fluke welds on Danforth-style designs or bent shanks on plough-types. The experience of Ted Goodwin, whose 43-pound cast aluminum Barnacle anchor catastrophically broke on the Bahama Bank earlier this year, is fortunately quite rare.

In terms of tensile strength and reliability, it is hard to beat a high-quality drop-forged steel anchor. Although some of the most highly regarded anchors are investment cast steel (the original Bruce anchor, for example), the tensile strength depends greatly on both the design and the quality of the casting.

As many anchor manufacturers move their production facilities to Asia, Practical Sailor has become concerned about the quality of cast-metal anchors. Lightweight alloy materials such as aluminum can further compromise the integrity of a cast anchor, with potentially disastrous consequences, as Goodwins story reveals.

Goodwin was anchored on the Bahama Banks in 8 feet of water with at least 7:1 scope out and 3/8-inch chain rode with a long nylon snubber. When a 4 a.m. squall rolled through, the boat lurched violently to the right and began blowing downwind. Deploying their back up anchor stopped the dragging after 300 yards. When Goodwin retrieved the Barnacle in the morning, its single fluke was missing completely.

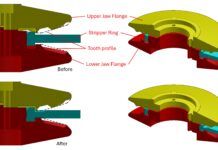

A close inspection of the broken section reveals a hollow area with a relatively thin wall thickness at the location of the break. Practical Sailor tested a steel Barnacle in 2007, but we could not locate the company recently, and the anchor appears to be out of production. These anchors can still be found on chandlery shelves, however. Based on Goodwins experience and our inspection of the break, the aluminum version of the Barnacle anchor is one we would avoid.