288

We’re 18 months into testing, and the all-star wood finish search continues. Practical Sailor launched a long-term durability test of varnishes and varnish alternatives in the summer of 2008 with 56 products; as we start 2011, 35 of them are still holding their own.

Because the life expectancy of a wood finish can vary from a few months to several years, we knew this evaluation would be a lengthy endeavor—a test of the finishes’ endurance and our patience. And so here we are, a year and a half after mounting the test panels, with some failed coatings and others that have aged less than gracefully, but no sign of the finish line on the horizon.

We opened this series of reports with a look at the coatings’ application and initial gloss in the August 2007 (one-part varnishes), October 2007 (varnish alternatives), December 2007 (two-part varnishes), and April 2008 (teak oils and stains) issues. Reports on the coatings’ durfability at six months and one year ran in the May 2009 and December 2009 issues, respectively. Here, we offer the 18-month report on those that have survived.

What We’re Testing

Our goal with this test is to determine the top exterior wood finishes in each category (one- and two-part varnish, teak oil, varnish alternative, etc.) and to find an overall all-star wood coating. There’s no one-size-fits-all solution when it comes to wood finishes, but in our opinion, the ideal finish is relatively easy to apply, easy to maintain, lasts multiple seasons, and is affordable.

“Easy to apply” and “easy to maintain,” however, can be very subjective concepts. The boat owner who considers the painstaking preparation and careful application requirements of a two-part varnish to be a sort of therapeutic meditation interprets the terms much differently than the one who regards brightwork maintenance as a form of torture.

With that in mind, PS designed this test to encompass all types of wood coatings, enabling every boat owner to find the finish that best matches his taste, potential labor investment, and wood protection needs. It’s up to you to decide what’s therapy, what’s torture, and what’s worth it.

When choosing a wood finish, knowing the pros and cons of each finish type is helpful. One- and two-part varnishes are clear, hard coatings that offer a deep, classic mirror-like finish. Prep, application, and re-application are more labor-intensive than with other finishes and require a more skilled hand, but they usually need less frequent maintenance and are more durable.

The top selling point for varnish alternatives is their ease of application: They require fewer coats than varnish, dry faster, and require little or no sanding between coats. The softer, flexible finishes need to be re-applied more frequently than varnish and generally do not last as long, but re-application and maintenance are a breeze. Although some can be overcoated with a glossy sealer, they don’t have the high-gloss finish of a hard varnish and often are pigmented. These opaque stains mask the wood’s grain somewhat but are touted as offering better UV protection than traditional clear varnishes.

Teak oils and sealers are favored for their ease of application, nonskid properties, and resistance to blistering. They are not as durable as other finishes and require frequent re-application, but they are easier to maintain. Teak-oil critics say they attract dirt and encourage mold and mildew growth, which we found to be true in some of our test panels.

288

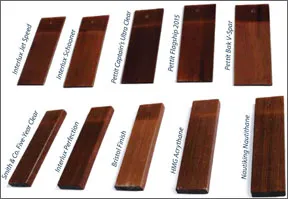

When this long-term exposure test began, the test field comprised 22 one-part varnishes, six two-part varnishes, 18 synthetics and stains, and eight teak oils. The test products included tried-and-true coatings and market newcomers from such resident boatyard names as Interlux, Epifanes, Pettit, Star brite, Signature Finishes, and West Marine; we also tested hardware-store brands like Ace and Min-Wax. The field has been pared down some in the last 18 months: None of the teak oils performed well enough to make it past the year mark, and nearly half of the teak treatments were cut from the line-up.

As we’ve noted in the past, marine coatings is an ever-evolving market, so it’s no surprise that over the course of a years-long test, some products are discontinued, re-formulated, or fall victim to the slowed economy. At the same time, new products are hitting store shelves regularly as coatings makers advance their own search for the ideal wood finish.

Since this evaluation began, Pettit discontinued the Bak V-Spar and Interlux reformulated Perfection (now Perfection Plus), boosting UV protection. Interlux also discontinued its Jet Speed and Goldspar, and replaced its Schooner varnish with Schooner Gold, which is said to offer better UV resistance; however, the maker re-released the original Schooner when its 2010 quick-dry finish, Compass, was recalled after a few months of production (Mailport, May 2010).

WoodPlus Coatings also has re-formulated its product: The coating we tested was labeled WoodPlus Marine Natural, but the current formulation is being sold as WoodPlus Ultra 10 Natural. According to the manufacturer, the only difference between the two is that the Ultra 10 has fewer VOCs (volatile organic compounds), making it more environmentally friendly.

Smith and Co.’s Five-Year Clear, a well-known two-part varnish, has been temporarily discontinued. The manufacturer cited the U.S.’s lagging economy for the halt. “The Five Year Clear will be made again when the economy recovers and consumer demand returns,” explained owner Steve Smith. “We are accumulating a waiting list.”

We’ve decided to keep the discontinued and re-formulated products in the test line-up as their performance is still relevant for comparison. New products have been put into testing in the field (See “Test Boats,”) or have been added to the roster for our next round of wood finishes testing.

Testers are evaluating the wood coatings on how well their coating integrity, gloss, and color fare over time with constant exposure to the elements. The results will help determine which type of coating offers the best and longest protection and which products stand out among their peers.

How We Tested

Each test product was applied per makers’ instructions to a 6- to 8-inch panel of bare solid teak, and each panel was assigned a number for blind judging. In instances where manufacturers gave a range for the number of coats to apply, testers went with the minimum.

We rated each product’s ease of application—how smoothly it went on, how complete the instructions were, and how simple the process was. Testers also rated the varnishes’ original gloss and reflective qualities. Coatings intended to have matte or semi-gloss finishes, like teak oils and stains, received no “original gloss” rating. (For more on the products’ application, revisit the previous articles in this test series mentioned above, which detail application requirements for each coating.)

The 56 test panels were mounted on a wooden rack, and in the summer of 2008, the rack was set up at a 45-degree angle in an unobstructed area on the roof of the Practical Sailor workshop in Sarasota, Fla. The test setup ensured that all panels received the same amount of weather exposure. The top part of each panel was covered, creating a control area testers use for comparison over time. Every six months, testers disassemble the rack and rate the panels.

The test protocol does not include regular maintenance or touch-ups of the coatings, so users can expect the products to last longer on a boat when they are maintained regularly and re-applied before the finishes are too far gone. Check out the online version of this article for tips on keeping your brightwork in good health.

How We Rated

Coating integrity ratings take into account the entire panel. The ratings translate to real-world use like this: Excellent and Good ratings indicate that no maintenance is needed; Fair ratings mean the coating is due for a maintenance coat; Poor ratings mean that some TLC is long overdue and extra elbow grease would be required to bring the finish back to top form. Excellent ratings are given only to those with an uncompromised coating. Panels with Poor ratings are pulled from the test.

Color and gloss retention ratings are relative to the panel’s original finish, not that of other coatings. So even if a panel’s initial gloss rated only Fair initially, it can earn an Excellent for gloss retention if it maintained that same level of gloss for 18 months. Initial gloss and ease of application are relative to the field within each coating category; these were assigned immediately after the panels were coated.

288

Recommended coatings in the one-part varnish and varnish alternatives categories earned three Good or better ratings at the 18-month checkup, and those in the two-part varnish group earned two or more Excellent ratings.

What We Found at 18 months

Regular brightwork maintenance is a must, but how often you have to apply a fresh coat or do a few touchups depends a lot on what type of finish has been used. Our test results so far have backed the generally held knowledge that teak oils do not have the longevity of hard finishes, requiring re-application a few times a year, and that one-part varnishes should be maintained annually. None of the teak oils and sealers PS tested made it past one year, and a significant number of the one-part varnishes began showing signs of weathering between the 12- and 18-month marks.

The re-application times for varnish alternatives/teak treatments is less predictable, and vary by product. In this test, a handful failed after one year, but those that held on have shown little change in the last six months.

The two-part varnishes have performed as expected, living up to their reputation for exceptional durability. All six original test products are still hanging in there, and most aren’t even ready for a maintenance coat yet.

Four one-part varnishes slipped in coating-integrity ratings from Excellent to Fair: West Marine 5-Star Premium, Pettit Z-Spar Captain’s Traditional Amber, HMG K Type Varnish, and Epifanes Clear High Gloss. In real-world use, these would be due for some sanding and a re-coat, as would the HMG Berenice, whose ratings dropped across the board.

As testers reported in December 2009, some teak treatments (LeTonkinois) exhibited a dried-out look after 12 months. Now, after a year and a half, some one-part varnishes have begun showing the same reptile-skin look, including Pettit Captain’s Ultra Clear, Interlux Goldspar, HMG K Type Varnish, and Deks Olje. The tiny cracks are imperceptible from 5 feet away but the finishes look dull and ready for some maintenance attention.

Epifanes’ Wood Finish Gloss and Clear High Gloss, which have done very well in past tests, also showed signs of drying out—a significant change from their Excellent 12-month ratings, and proof that annual refresher coats are essential to maintaining a finish.

In the realm of varnish alternatives, coatings with more pigment/solids (intended to boost UV protection) like the Interlux Sikkens Cetol products and WoodPlus seem to be faring better than the others, and those with a varnish-like overcoat are also doing well. The orangey WoodPlus, for instance has maintained coating integrity for 18 months, although its low gloss has turned to no gloss.

The Cetol finishes—with the exception of the Natural Teak—saw few changes in the last six months. The Cetol Marine slid from an Excellent to a Good in coating integrity, and the Marine Light with gloss overcoat lost some of its luster, but it and the Cetol Marine with gloss held on to their Recommended status.

The category that saw the least change was the two-part varnish group. Five of the six coatings earned the same ratings at 18 months as they did after one year. The Smith and Co. Five Year Clear-coated panel was the only one to show any signs of change as it lost a bit of gloss. The Honey Teak panel’s coating has pulled away at the edges some, but that was reported previously and has not worsened over time. A touch-up would be fast and easy, requiring a bit of sanding and an application of the two-part system’s honey base over the existing clear topcoats.

The three test panels that notched Poor ratings for coating integrity— Deks Olje No. 1 with No. 2 overcoat, Interlux’s Cetol Natural Teak (without a gloss overcoat), and the Ace Polyurethane Clear Gloss—will be pulled from the test rack for the next go-round. That cuts the roster to 35 products advancing to the next round: Twenty one-part varnishes, six two-parters, and nine varnish alternatives.

Conclusions

Our search for the “ideal” wood finish—easy to apply, easy to maintain, protects for multiple season, and is budget friendly—is something of a dreamer’s mission at this point. We’ve yet to find a single product that meets all of these criteria, so there’s always some compromise involved in choosing a wood coating. It’s up to each boat owner to determine where he’s willing to make that compromise.

If you’re game for sacrificing some extra time (patience and sandpaper) up front in exchange for long-lasting protection and the sought-after wet-varnish look, then a one- or two-part hard varnish is the way to go. The two-part systems have held up the best so far, and all of those rated Excellent for coating integrity can be expected to last 18 months or more untouched.

For their continued deep gloss and top-notch protection, we recommend the HMG Acrythane XSC and Nautiking’s Nautithane, although the Nautithane is among the most expensive products in the test. The standout single-part varnishes thus far are Pettit’s Flagship 2015, Pettit Captain’s EZ Care 1016, and the Coelan with primer. Perfection also is performing well, but we aren’t recommending it since we haven’t tested the re-formulated version. The Coelan finish—the most expensive test product—was applied over a primer, a step we recommend when using this product. The Coelan test panel without a primer saw a dramatic change in color after one year.

At the other end of the spectrum are the teak oils and sealers. No product in that group made it to the 18-month checkup, but the Star brite Classic Teak Sealer as the longest-lasting one.

Boat owners looking to take the middle ground—in terms of labor versus protection and aesthetics—would do well to give one of the Recommended varnish alternatives a try. Though they lack the high gloss of varnishes, the Cetol products are easy to apply and maintain, and they last seasons longer than teak oils. The Cetol Marine with gloss and Marine Light with gloss get testers’ pick so far.

With 35 products still in the running in this test, we’re keeping our fingers crossed that our continuous search for the Holy Grail of wood finishes will one day lead us to the ideal solution, one that doesn’t involve compromise. Stay tuned for the two-year report on this exterior wood finishes test.