375

Walter Schulz arrived in Bristol, R.I., from Connecticut in 1975 in his pickup truck with an irrepressible desire to design and build beautiful, semi-custom offshore yachts of the highest quality. He rented a portion of the old Herreshoff yards and put together a crew of seven to build what would be the first of Shannon Yacht’s most popular designs: the Shannon 38.

The first Shannon 38 splashed into Narragansett Bay in 1975, setting the standard for all the offshore sailboats Shannon has since produced. The finished boat married the elegant look of the classical Herreshoff with the construction and design details that distinguish a bluewater voyager. It is a testament to the breed that hull No. 1,

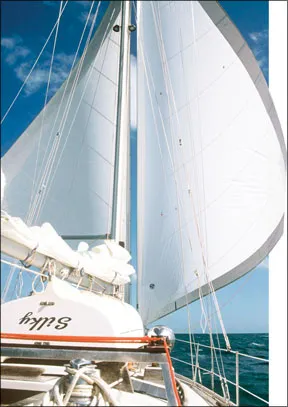

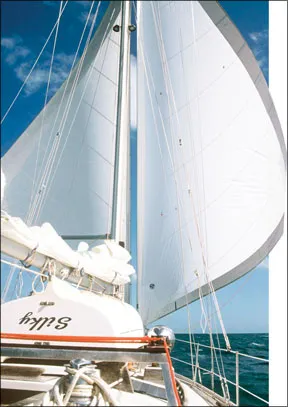

Long Passages

(owned by Bob Burns and Judi Nester), just completed a 14-year circumnavigation, though it is now over 30 years old.

DESIGN

With its traditional full keel, heavy displacement, and ketch rig, the Shannon 38 is a far cry from cutting-edge design. However, by successfully integrating a myriad of details required for shorthanded offshore passagemaking, the boat stands far above many of its contemporaries. A total of 99 Shannon 38s sailed away from the Shannon yard in Bristol between 1975 and 1984. During those years, Schulz extended the Shannon line by introducing the Shannon 28, 38 pilothouse, 43, and 50.

In the early 1980s, Schulz returned to the venerable design that had established the company, and the first Shannon 37 was launched in 1985. Above the waterline, the 38 and newer 37 were similar, though fuller sections in the aft quarter of the 37 were designed to increase stability when heeling and power when reaching. Below the waterline, the 38’s traditional full keel was replaced with a cutaway forefoot and a fiberglass-covered, stainless steel centerboard that retracted into a modified fin keel. The Shannon 37 drew only 4 feet, 3 inches with the board up, making it ideal for cruising the Chesapeake Bay, Intracoastal Waterway, and Bahamas. Nineteen were built between 1985 and 1993.

The Shannon 37 and 38 are traditional designs. The relatively heavy displacement and long keel on both boats makes them seakindly. Both hulls track very well, even running dead downwind, which means a windvane or electric pilot can maintain control in nearly all conditions. While performance will suffer in light coastal breezes, the conservative sailplan is well adapted for shorthanded passagemaking. At 11-foot, 6-inches, the max beam is about the same as a similarly sized, modern coastal cruiser, although it does not carry as far aft, reducing interior volume in the stern.

Like most boats this size, too much weight in the bow will cause the Shannon 37 and 38 to hobbyhorse. Running in serious storm conditions, the Shannon’s small, almost heart-shaped transom will rise over the largest of waves, so long as the stern is not loaded down.

The majority of Shannon 37/38s (60 Shannon 38s, five Shannon 37s) are cutter-rigged ketches with a staysail on an inner forestay and two parallel headstays. This rig divides the sailplan up into many small sails, which makes the boat easy to handle and gives the crew many different sailplan options. The others are cutters with the same parallel headstay arrangement. The cutter rig has somewhat better windward performance, while the ketch rig offers a greater variety of sail combinations running downwind in the trades.

Typically, a headsail furler is fitted to one of the two parallel headstays, and a hank-on headsail is flown from the second headstay when running downwind in the trades. The parallel headstay arrangement causes considerable chafe on the furling sail at certain wind angles. The stresses on the masthead crane from the two headstays can also cause cracking of masthead welds. But for a downwind passage, the advantages of the double headstay arrangement outweigh the disadvantages. Other sailors may want to remove the second headstay and use a flexible furling system to fly a large reaching or running sail in lighter winds. Most Shannons were fit with a self-tacking staysail on a club, which makes for ease of handling when tacking, but limits the size and compromises the shape of the staysail. On the ketch rig, a mizzen staysail can boost horsepower when the wind is on the beam and aft.

The centerboard on the Shannon 37 gives it better performance to weather than the Shannon 38, but neither are greyhounds on this point of sail. The centerboard trunk is below the waterline, which means that the boat must be hauled to fix any problems with it. The fiberglass trunk top was originally secured with a permanent sealant and bolts, making it difficult to open. Later 37s were built with a stainless trunk top that was easier to open. On some 37s, a host of different metals were used inside the trunk, creating electrolysis problems that damaged the stainless steel pendant or the bronze sheave it ran through. Unless you need the shoal draft, the Shannon 38’s full keel is less hassle.

DECK LAYOUT

The diamond-patterned fiberglass on the decks of all the Shannon sailboats makes for excellent nonskid and is emblematic of the focus on offshore safety evident throughout the deck layout. The sidedeck is wide, and the teak toerail is adequate. Solid teak handgrips run down either side of the coachroof. On the foredeck, the staysail club and staysail stay can be used as handgrips. The high lifelines and solid pulpits at bow and stern are reassuring.

At bow, stern, and midships, solid stainless-steel cleats large enough to hold two 5/8-inch lines in a proper figure-eight are through-bolted into the deck. Well-positioned bronze or stainless fairleads for the bow and midships cleats set into the teak toerail prevent chafe on snubbers and docklines while leading lines fair from almost any angle. Two large anchors can be deployed or retrieved easily from the anchoring platform. One bow roller is located about midway along the starboard side of the bowsprit, and another is placed at the end of the bowsprit on the port side. Separate deck pipes lead down to the divided chain locker, which cannot be accessed from the deck. The design is safe offshore, but it is inconvenient in an anchorage, where you’d have to go below to clear jammed chain.

The traditional-looking teak and frosted Plexiglas hatches, while handsome, tend to leak over time. Upgrading to top-of-the-line, offshore-rated hatches is recommended for any long passage. The sea-hood also tends to leak on older boats and will need to be rebuilt with extra gasketing material to be watertight.

The solid-teak toerail traps water on the deck, and the scuppers in the side deck have trouble removing water quickly enough in a big sea or a heavy rain. The large cockpit could also be fitted with better drainage for clearing green water. On some Shannons, the diesel tank breather exits the boat through a fitting in the side of the cockpit seat, making it vulnerable to flooding if the cockpit is pooped.

On the other hand, the cockpit is very comfortably laid out for sailing, watchkeeping, or for cocktails. The helm seat is humped and the deck angled behind the wheel, making for comfortable positions whether sitting or standing, even when steering for hours at a time. The cockpit seats are long enough for napping. Adequately sized primary and secondary winches are located on the coamings, and the mainsheet winch is located next to the companionway. The bridgedeck is high enough that the crew can leave the cabin without removing the hatchboards in heavy weather.

Depending on the interior layout, large lockers are located under either one or both of the cockpit seats. The lockers are sealed with hollow tubing gaskets and have drainage channels, but water can still find its way through on occasion. The batteries are located in this locker on most of the Shannon 37s, which makes the power supply somewhat vulnerable to water intrusion. Other water-sensitive equipment should not be installed in this locker.

ACCOMMODATIONS

Shannon prides itself on being a semi-custom boatbuilder, but you can’t get too creative with only 31 feet of waterline. Most 37s and 38s have one of two interior layouts with only relatively minor variations. However, the layouts vary significantly in terms of interior volume and stowage, and those differences are worth considering.

288

The main difference between the two layouts is the location of the head. In one, the head is aft, at the base of the companionway, with a hanging locker for wet gear behind the toilet. In this design, the navigation station faces outboard in front of the head compartment with a freestanding chair for the navigator.

In the other layout, the head compartment is placed forward, just aft of the forepeak. In these boats, the navigation station is oriented athwartships and located on the port side at the base of the companionway. The navigation table is larger than in the first design, with a small hanging locker built into its base. A quarterberth extends aft under the port cockpit seat behind a bench seat with a half-height backrest for the navigator. In deciding between these layouts for offshore voyaging, the quarterberth and larger navigation station must be traded off against the convenience of having a head right by the companionway and the comfort of a real navigation seat.

The attention to detail is what really sets this interior apart. Teak handgrips line the overhead on either side of the cabin, always within reach. The galley sinks are deep enough to keep water in even when heeled at 30 degrees, and close enough to the center of the boat that they rarely backfill.

Deck hardware, fuel and water tanks, and electrical conduit are accessible, though several teak trim pieces might have to be removed first. Even the headliner has been designed so that it can be removed without damage. The two opening hatches, six dorades, and eight opening portlights provide adequate ventilation even in steamy tropical climes.

The finish was also specified by the owner, but in most of the older 38s, high quality, matched teak was used throughout, which makes for a beautiful, but dark interior. The white paneling on the coachroof and headliner help to brighten up the interior considerably. A solid teak-and-holly sole was standard on both the 37 and 38, excellent nonskid in wet weather. Over time, galley countertops from butcher block to Corian, a major improvement, both practically and aesthetically.

While most of the tankage in the 38 can be accommodated below the waterline, the centerboard trunk takes up prime stowage areas on the 37. Water tanks are located under the settee berths on the 37, and the fuel tank is under the quarterberth. These areas can be used for stowage on the Shannon 38, greatly increasing the amount of stores and/or equipment that can be carried.

SYSTEMS

Though simple by today’s standards, the systems on the Shannon 37/38 are generally of high quality. Generous inspection ports allow for steam cleaning of fuel and water tanks. The fuel tank has a sump that will collect contaminants, though this cannot be drained from below and must be pumped out through the inspection hatch. While Shannon used bronze through-hulls and seacocks below the waterline, many of the fittings in the rest of the boat are PVC or nylon, including the above-waterline through-hulls for the deck scuppers, and these are prone to breakage as they get brittle with age. (Shannon switched to stainless through-hulls 10 years ago.)

The batteries on the Shannon 38 are located under the quarterberth, while those in the 37 are located in the cockpit locker. In both cases, the stock batteries are well-secured, but the cockpit locker location on the 37 is harder to access and doesn’t allow much room for additional batteries.

Wiring throughout the boat is marine-quality, tinned wire color-coded by function. The early Shannon 37s and 38s were powered by a 40-horsepower Westerbeke or Perkins, and the later models had 44-50 horsepower Yanmars. Accessing the engine is not without its difficulties (three cumbersome pieces of teak at the front and rear access through the cockpit locker), but it is better than on similar boats.

PERFORMANCE

On both the Shannon 37 and 38, the propeller lies in a relatively small aperture between the skeg and the rudder, which protects it from lines and logs, but reduces motoring efficiency. At 2,200 rpm in flat water, the 40-horsepower Shannon 37 motors at a bit less than 6 knots. When fully loaded for cruising, the boat will lose a half-knot to a knot of speed under motor. Like most boats with traditional underbodies, the Shannon 38 doesn’t like backing. Even with its modified fin keel, the Shannon 37 can be unruly in reverse.

Under sail, both boats’ passage averages reflect their heavy displacement and traditional designs. Burns and Nester averaged about 120 miles per day during the course of their 14-year circumnavigation. Well-known bluewater voyagers Beth Leonard and Evans Starzinger averaged 117 miles per day over the course of a three-year circumnavigation on their Shannon 37,

Silk

, including periods becalmed and hove-to. That means that the Shannon 37/38 is a 5-knot boat on average over a wide variety of conditions. However, in winds of 20 knots and more, the boat does considerably better, averaging 150 miles per day.

With the ability to easily carry double headsails, the more standard ketch rig, and the long keel, the Shannons are optimized for the downwind work of a typical westabout tradewind circumnavigation. The boat performs well from a dead run up to a close reach, but performance falls off markedly as the apparent wind shifts forward. Starzinger and Leonard reported that their ketch-rigged Shannon 37 with the modified fin keel could sail up to 38 degrees apparent and tack through 100 degrees in flat water when lightly loaded. Fully kitted out for cruising and in big seas offshore, the boat could tack through a minimum of 110 degrees. Burns and Nester said their ketch-rigged 38 performed similarly in offshore conditions. The cutter-rigged Shannon 38 will do slightly better.

The traditional underbody configurations may not match modern performance cruisers to windward, but they make heaving to simple. Starzinger and Leonard’s Shannon 37 hove to on the mizzen alone and lay about 50 degrees to the wind, making a knot and a half of leeway dead downwind. In winds over 40 knots, a reef in the mizzen kept the boat comfortably in the hove-to orientation.

Nester and Burns said they needed to heave to only once in 14 years on their Shannon 38. “We used the staysail, triple reefed main, and reefed mizzen. The windvane was set up to keep us into the wind—we forereached slowly.”

CONCLUSIONS

The new Shannon 39 costs $660,000. When the Shannon 38s and 37s were built, they were among the priciest offshore boats on the market. But as the Shannons have aged, their prices have come more in line with offshore production boats of the same vintage. Today, a Shannon 38 built between 1980 and 1985 can be purchased for between $100,000 and $120,000, about the same as for a Pacific Seacraft 37 of the same age and only about $25,000 more than for a Tayana 37.

A 25- or 30-year-old sailboat from any manufacturer is going to need some attention before heading over the horizon, but the initial quality of the Shannon build should translate into less money spent on the refit than for other production boats of the same age. While you may have to replace the engine or the rigging, the basics will be right on this boat, so you won’t be trying to rebuild the bow pulpit or figuring out how to shoehorn in more tankage. That said, like most boats in its size and age range, it was not designed to carry all the modern goodies and gadgets. Cruisers will be hard pressed to fit a generator or air-conditioning aboard. If that’s what is needed to go cruising, look for another boat. But those looking for an affordable older boat that is designed and built to be taken offshore should definitely put the Shannon 37/38 on their short list.