David Boye, the Arizona knifemaker whose unique folding boat knife of cast dendritic cobalt won our June 2000 sailors knives bench test of 14 knives and was a reference standard for our March 2004 test of 18 knives, recently introduced a new model Basic 3 Cobalt knife.

These knives doggedly retain a cutting edge when going through tough, blade-resistant materials like rope, cardboard, or even old rugs. Others give up long before the job is done. In our experience, Boyes cobalt knives last much longer-and when they finally do slow down, they can be resharpened with just a few strokes on a medium stone. The difference, we reason, is in the metallurgy.

Boyes cobalt blades are “cast to shape and retain the pristine crystal network of highly dendritic (branching) bonded carbide throughout the blade, which aids in cutting and maintaining the structure of the cutting edge,” according to the maker.

Most knives are from steel that originally contained a similar crystal microstructure, but then underwent rolling, stamping, or forging to shape. This process breaks down the original carbide microstructure of the metal. The carbides at the edge are then no longer rooted into the overall microstructure. Complex heat treatment is then applied to develop properties such as hardness and toughness.

Each sharpening of the Basic 3 exposes fresh hard carbide micro-teeth. The cobalt blade material is “completely impervious to seawater corrosion and is non-magnetizeable.”

The Basic 3 has a hand-filling handle wrapped in black paracord, and a hefty 4-inch, plain-edge, drop-point blade with enough “belly” and hand clearance from the cutting surface to stand in as a chefs knife. The finger guard is faceted with the same angle as the cutting bevel, providing a sharpening guide-a repeatable angle that shortens an already quick job by reducing the number of unproductive strokes across the sharpening medium-strokes that undo work already done, the bane of inexperienced sharpeners. The ambidextrous, multi-wear nylon sheath features a molded brass insert that acts as a spring to retain the knife without a keeper.

The Basic 3 also provides a scraping surface (last 2 inches of the top of the blade is flat and thick) and a hammering surface (butt of handle). The new Boye costs $360 and is available direct from Boye Boat Knives.

Redi-Edge Sharpener

In August 2005, we evaluated knife-sharpening devices in three classes, favoring types that help the user to maintain a given edge-bevel angle. Our recommendations of angle-assist or variable-angle sharpeners still apply for regular blade maintenance, as well as initial edge preparation.

Onboard, unplanned edge maintenance is, however, likely on any outing longer than a day sail. The process may be somewhat easier with the keyring-sized, -ounce Redi-Edge Tactical Pro ($23) from Klawhorn Industries. It combines an angle-assist device and a diminutive ceramic-coated freehand sharpener with rounded edges for serrations.

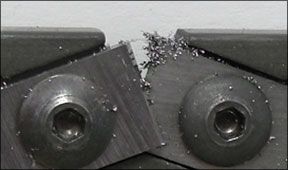

Hold the Redi-Edge on a flat surface and lightly draw the knife edge through the 20-degree edge angle formed by two small, hardened cutting inserts. For serrations, use the rounded corner of the device, or sharpen on the flat side in the conventional manner. On another ceramic surface, there is a groove for pointed tools.

For knives maintained at the sharper 10- to 15-degree angles, a few strokes with the Redi-Edge will produce a small secondary bevel that strengthens the edge with only a slight reduction in keenness, serving well for quick onboard edge maintenance. But be aware that a regular diet of this kind of sharpening can prematurely reduce the service life of your knife. Stick with the recommended tabletop models when you can, as they sharpen your blade by gentle abrasion rather than stripping away metal.

The Redi-Edge angle-assist cutters are available with aluminum and stainless handles and concealed ceramitized rods. They range in price from $23-$35.