As spring fast approaches (it’s coming, I promise), a few of our less fortunate sailing brethren discover their house bank batteries can no longer hold a charge. One of the most common questions we get regarding deep-discharge batteries-those batteries designed to power our lights and electronics-is whether to go with a gel-cell, AGM, or flooded lead-acid wet-cell battery.

If you’re the handy, thrifty type, and you watch battery electrolyte levels as closely as you watch your wallet, the good old, flooded lead-acid battery is hard to beat. In 2008, cruiser Andy O’Grady showed us how he stretched eight years of hard use out of his high-quality lead-acid. While living aboard, my wife Theresa and I had similar results with wet-cells-in our case, the heavy-duty Trojan 6-volts wired in series to produce 12-volts.

The downside is that these batteries self-discharge at a much faster rate than sealed batteries, so if your boat does a lot of sitting and little sailing, the sealed batteries have an edge. For most of the boating public, the low self-discharge, low-maintenance (and reduced risk of spillage) of a sealed battery is very attractive. These batteries are more expensive, and because they are sealed, they can be cooked for good, if the charge cycle is not well-regulated. Before you run out and buy new batteries, make sure your charging system is up to snuff, or youll just go through the same routine in a year.

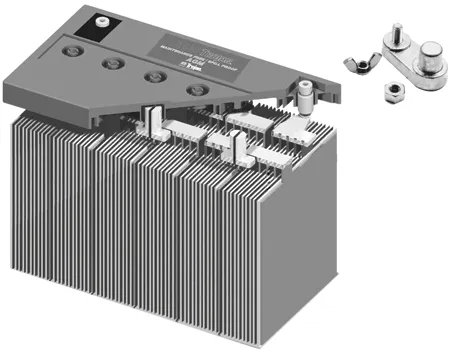

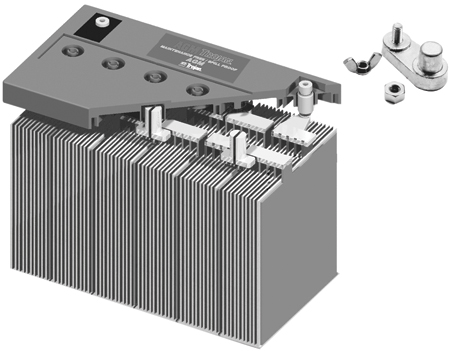

Courtesy of Trojan Batteries

Sealed Batteries

The chemical reaction that occurs inside of the sealed cases of AGM and gel lead-acid batteries differs from that of flooded-cell batteries. AGM and gel batteries undergo a recombinant chemical reaction during recharging, whereby oxygen and hydrogen recombine inside of the battery. This reaction is achieved by a gas phase transfer. Oxygen that is normally formed on the batterys positive plates during a recharging cycle migrates to the batterys negative plates and subsequently gets absorbed.

As a result, hydrogen gas normally produced at the negative plates of a flooded cell battery is suppressed, as the oxygen recombines with the hydrogen to form water. This design prevents the escape of hydrogen and oxygen gases under normal operation and aids in retaining moisture inside of the cell, making the recombining process normally 99 percent efficient. The individual cells of all AGM and gel batteries are fitted with special pressure-relief valves. The acronyms VRLA (valve-regulated lead-acid) and SVR (sealed valve-regulated) batteries are often used to describe this group of batteries. Never manually open the pressure-relief valves on a VRLA battery, because atmospheric oxygen will enter the battery and contaminate the entire cell, effectively ending your batterys life and warranty.

Gel Batteries

Gelled batteries use an electrolyte that has been thickened to the consistency of petroleum jelly by the addition of a silica agent. The agent allows the electrolytes water to bind with the acid. Once inside, the gel undergoes a chemical reaction, heats up, and liquefies. During the cool-down phase, the gel solidifies and tiny hairline cracks form between the gel and the batterys plates. During the charging, oxygen gas from the positive plate combines with the hydrogen gas on the negative plate inside of the cracks, producing water. The gelled electrolyte will then absorb the water, which keeps the closed system hydrated.

AGM and gel batteries require a well-regulated charging system. Gel batteries are extremely sensitive to charge voltages above 14.1-volts DC at 68 degrees. If you don’t have a voltage regulated, three-stage battery charger with temperature compensation or an alternator with a three-step regulator, then you should expect to get about half of the batterys rated life cycle.

The upside of gelled electrolyte batteries is that they recharge much faster than flooded-cell batteries, provided that a regulated charge voltage is temperature compensated and is at least 13.8 volts DC, but no more than 14.1voltsDC. (These voltages are averages; each battery manufacturer has its own recommended voltage levels, which must be strictly adhered to.)

In addition, the gels self-discharge rate is extremely low. Flooded-cell batteries self-discharge 1 percent per day or 30 percent per month (at 68 degrees), while VRLA batteries self-discharge generally less than 2 percent per month. This can be quite an advantage when laying up your vessel at the end of the season.

AGM Batteries

Absorbed glass mat (AGM) batteries use the same chemical recombination reaction as a gelled battery. But the AGM battery is fitted with an absorbent, matted glass fiber insulation material that is machine compressed between each of its lead plates. Unlike the gel cell, whose pasty electrolyte is loose inside the case, the AGMs electrolyte is 95 percent absorbed into the glass fiber separation mats by capillary action.

AGM batteries, like most VRLAs, require precise, voltage-regulated, temperature-compensated charging routines. AGM batteries can accept a charge rate of up to 75 percent of their rated amp-hour capacity. Thus, a 200Ah AGM battery will readily accept a 150-amp voltage regulated charge. Because AGM batteries normally require a higher re-charge voltage (about 14.2V absorption, 13.5V float, see specific battery manufacturers for recommended voltages), they end up having a higher terminal voltage and subsequently higher cranking amp capacities than other types of battery technology.

One type of AGM battery breaks ranks with an unconventional internal design and has a remarkable range of recharging voltages: the spiral-cell AGM battery like the Optima and Exides Orbital. Each cell consists of two long thin plates of high-purity lead (one positive and one negative) with a layer of electrolyte-laden absorbent glass mat in between. The materials are then rolled up tightly into a cylindrical shape and pressed into the batterys six pack containment case.

Spiral-cell recharging requirements are much more liberal than other VRLA designs. Optima recommends that its deep-cycle model be recharged at a constant voltage of 14.7V, with no current limits as long as the batterys temperature stays below 125 degrees. These parameters are much in line with the output from a standard alternator. Neither Optima nor Orbital offer a VRLA battery larger than a 75 Ah group 31.

If your vessels house battery bank is frequently and deeply discharged, then gelled electrolyte batteries would generally yield the longest product cycle life. If your boats house bank is not that frequently nor deeply discharged, then an AGM battery would provide longer service life. Atlhhough gels have a loyal following among cruising sailors, AGM batteries are far more popular in the wider market. Whichever route you take, you want to make sure your charging systems (solar, wind, shorepower, and alternator) have the set points (the point at which the regulator stops or adjusts the charging rate) specified by the manufacturer for ideal performance. This is particular important for gel cells, which have slightly lower charging voltages, and can be cooked prematurely at the higher-set points.

Battery Terms

Ampere hour (Ah): The amount of current expressed in amps that a battery can deliver at 80 degrees, multiplied by the hours it can deliver the current without falling below 1.75 volts per cell (10.5V on a 12-volt battery).

Cold Cranking Amps (CCA): The amount of current expressed in amps that a battery can deliver for 30 seconds at 0 dgrees and maintain a minimum of 1.2 volts per cell (7.2V across the terminals during load on a 12V battery).

Marine Cranking Amps (MCA): Same definition as CCA with the exception that the temperature limit for MCA is 32 degrees.

Reserve Capacity (RC): The amount of time expressed in minutes that a battery is capable of delivering 25 amps of power at a temperature of 80 degrees without falling.