Weighty and solid, this new mainsheet traveler offers strength, performance, and redundancy at an attractive price.

Garhauer Marine is a name that has appeared in these pages with regularity over the years, and in almost every instance those references carry adjectives like “robust,” “sturdy,” and “economical.” One of the latest products from this Upland, Calif., company—an established manufacturer of blocks, line organizers, vangs, and other deck hardware—is the Unibody Mainsheet Traveler. Unibody (UB) is the term company president Bill Felgenhauer and his colleagues have given to their line of gear in which the principal components are machined from solid pieces of metal (See Unibody Blocks, “Chandlery,” PS, Nov. 1, 2004.) This traveler deserves some of the same descriptions.

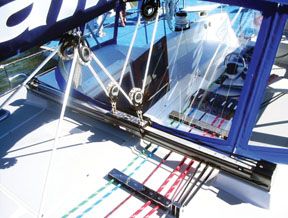

When PS last tested mainsheet travelers (the report was published in the June 2005 issue), Garhauer’s Unibody system was just being introduced, and thus wasn’t included in that evaluation. This system is based on a stout I-beam-shaped track extruded from 6061 T-6 aluminum, which is hardcoat anodized. One notable difference between Garhauer’s traveler and the majority of those PS tested for the 2005 article is that the base of this track is nearly double in size, adding substantial weight, but also rigidity so that this product can easily span cockpit footwells or companionways unsupported.

However, the primary distinction of the UB travelers is that the sheaves on which the traveler’s control lines turn are integrated into the car, end fittings, and the track. The advantage of this, according to Guido Garguilo, Garhauer’s in-house traveler specialist, is that this arrangement minimizes snags. And having the sheaves integrated in this fashion also means that their Torlon ball bearings aren’t exposed to damaging UV rays. Another difference is that the UB traveler system’s control lines have a 5:1 purchase; the others PS tested for the June report were 4:1.

Unibody traveler systems come in three models for boats from 27 to 60 feet LOA. On the midsize MT-UB-2, which is intended for boats from 33 to 45 feet, the anodized aluminum car is a full 10 inches long, 4.8 inches wide, and stands nearly 3 inches tall. (This whole system, including 5 feet of track, car, end fittings, and control lines, weighs 33 pounds. Those that PS tested six months ago average 20 pounds.) The track itself is 2.3 inches high, 1.5 inches wide, and more than 0.5 inches thick at the narrowest point. Beefy is the appropriate adjective here.

The reason for this oversized equipment, according to Garguilo, is to resist torque and distribute the loads from the mainsheet over a greater area of the track, which promotes better control, he said. It’s suitable for mainsheet loads up to 4,000 pounds, and can span areas up to 5 feet unsupported.

The track itself comes bored with countersunk holes for 1/4-inch bolts on 4-inch centers. The car moves along the track by means of four separate races filled with Torlon ball bearings, one race in each corner of the car. The placement of the races, Garguilo told us, counteracts torque even under heavy loads. Stainless steel bolts (3/8 inch) with firm rubber caps serve as the stoppers at either end of the track. To remove the car for inspection, you have to take one of these bolts out, which wouldn’t be an easy task, and depending upon where the track was mounted, it might also have to be unbolted from the deck to remove the car. But all the sheaves can be easily removed for inspection because their Torlon bearings are captive and won’t fall out.

All the components of this system—end fittings, mainsheet connection shackles, sheaves, etc.—are fixed in place using stainless bolts with hex heads. Except for the stainless bushings at the center of each aluminum sheave, everywhere that dissimilar metals come into contact, Garhauer applies Tef-Gel (a lubricant paste commonly used in the marine industry) to inhibit corrosion and seizing. According to Garguilo, the Tef-Gel also prohibits the intrusion of moisture.

We judged the motion of the UB traveler car to be almost equal in smoothness to the travelers from Antal Marine Hardware and Harken Yacht Equipment, which tied as winners in that portion of our recent test. Garhauer uses three elongated, D-shaped shackles to connect the blocks of the mainsheet purchase system. All of the other travelers we tested had only one attachment point.

And unlike all but Schaefer’s traveler system, these shackles pivot in an athwartships plane. The result is that the center of effort angle on Garhauer’s UB traveler is much greater than all of those in our last test. (PS used center of effort angles in that test to rate each traveler’s ability to handle torsional loading—the greater the angle, the lesser the ability to handle such loading. The angles are defined by a triangle drawn using the width of the track at the point where the bearings touch it as the hypotenuse, and the pivot point of the car’s mainsheet toggle or shackle as the apex of that triangle.) Despite this assessment, we doubt the UB Traveler will have any problem withstanding torsional loads due to the oversize aspect of all its components.

The Unibody Traveler is sold fully assembled—including end fittings and traveler control lines. The PS test version cost $495. That’s $174 less than Lewmar’s mainsheet traveler, which we judged as the overall winner of the most recent test. All you need to do is mark your holes, drill them, and mount the track on deck. Though this product can’t be modified for crowned decks, it does carry a 10-year guarantee. If bullet-proof is what you prefer in deck hardware and weight isn’t a consideration, this product should serve you well.

Contact – Garhauer Marine, 909/985-9993, www.garhauermarine.com.

Also With This Article

“Value Guide: Mainsheet Travelers”