After my recent post on portable marine heaters and insulation, a few people asked our opinion of liquid petroleum gas (LPG) heaters. Simply stated: We are not fans of portable LPG systems on boats. A boat fire in New England last month offered a pretty good example of the risks inherent with this type of equipment. Even fixed propane heating (and cooking) systems that employ all the safety precautions recommended by the American Boat and Yacht Council or comparable advisory bodies can be dangerous, if they are neglected.

In the first part of our upcoming series of tests of propane system equipment, marine surveyor Capt. Frank Lanier outlines the basics of marine propane systems. During his years inspecting old and new sailboats, Lanier has seen it all, but hes still amazed at the devil-may-care attitude that some owners have toward marine propane systems.

Because propane is heavier than air, it can slip into the bilge undetected, where a spark can set the boat ablaze. Propane locker explosions have also occurred. While industry standards aim to prevent this sort of disaster on new boats, even perfectly installed systems require vigilance on the part of the owner. Checking for leaks should be part of the regular routine before using any LPG device on board.

Here are some of his observations on propane safety:

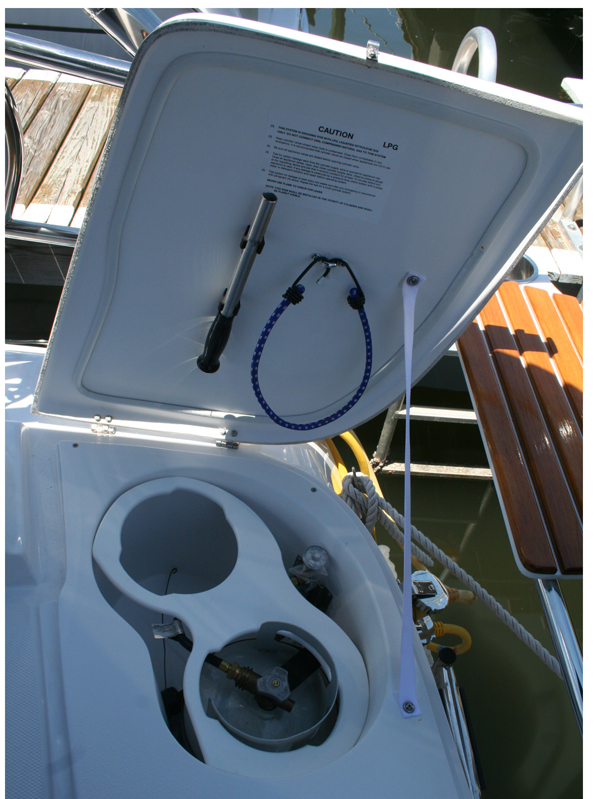

Every LPG system in the United States is required to have a pressure regulator designed for use with LPG. These pressure regulators have relief valves that can vent gas, so it is critical that this gas cannot make its way onboard. For deck-mounted cylinders, verify the regulators relief-valve outlet discharges outside the boat at least 20 inches from any opening on the boat. Most lockers will have an overboard vent, but if the vent line has any dips in it, gas can collect and pose a risk.

LPG systems are also required to have a pressure gauge installed on the cylinder side of the pressure regulator. This gauge allows you to quickly and easily check the system for leaks via a leak-down test. To conduct a leak-down test, turn on the stove or grill, then close all the burner valves, leaving the solenoid switch on. Note the pressure gauge reading, then close the tank valve – the gauge reading should remain constant for at least three minutes. If the pressure drops, then you have a leak (or leaks) and must inspect the entire system before using it again.

Leaks typically occur at fittings and connections, although they can occur anywhere in the system due to chafe or physical damage to supply lines or other system components. Use leak-detection fluid or a detergent solution to locate leaks. Dont use solutions containing ammonia (it attacks brass fittings), and unless you want top-billing at the Darwin Awards, never use a flame to check for leaks.

A word on leak prevention at fittings. Typical marine LPG system connectors include 1/4-inch or 3/8-inch NPT (National Pipe Thread) and/or 45-degree SAE (Society of Automotive Engineers) flare connections. Only NPT fittings require the use of polytetrafluoroethylene Teflon (PTFE) tape or thread sealant on the threads. SAE flare connections are self-sealing.

Using Teflon tape or thread sealant (also called pipe dope) boils down to personal choice, as both will work fine. Just use one or the other; using both is not recommended. Be sure to follow the manufacturers instructions. If you opt for tape, use the yellow PTFE Teflon tape, which is specifically designed for for LPG systems. Its thicker and more durable than the white tape, which is normally used for water pipe joints.

Check your LPG system regularly for leaks or anytime you fire up that stove or grill. Installation of a marine-grade, LPG sniffer or fume detector is also highly recommended. If you have one installed, ensure the gas sensor is mounted as low as possible and near the range (where leaking gas is likely to accumulate), and test sensor operation on a regular basis. Other desirable safety upgrades include installing smoke and carbon-monoxide detectors.

After cooking, leave one burner ignited and turn off the solenoid or tank valve. When the burner goes out, close the burner valve – this empties the line of gas and prevents leaking should a burner valve fail to seal. Its also a good idea to manually close the tank valve in addition to the solenoid valve if the system is not in use, particularly if you plan on leaving the vessel for an extended period of time. The solenoid should always be closed when the system is not in use.

Curious why is it ok to leak down after the 3 minutes, we have that situation where after 15 minutes after the valve is closed the needle slowly drops down.